-

Posts

93 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by aaamax

-

-

There is no need to quote what we all just read.

I had my eye on a 300# Soderfors so I can relate. When you do get your monster anvil, I bet you will indeed use it. The rebound I have found on heavier anvils is sometimes unreal and once you get used to that, there is no going back.

Cheers mate!

-

There is no need to quote what we all just read.

That is a gorgeous stand you made up for that big-boy. And BIG it is! I will probably pattern my stand after yours.

Cheers.

-

Didn't even think of that! Indeed, that would have made it a whole lot easier. Maybe it was a sense of "getting out of there with the loot before he changes his mind" that kept me from thinking straight.

next time I will remember this for sure,

thanks.

-

100Kg... xxxx! a true monster.

I've used wood at the foot with good effect in the past. am guessing that with such a stout unit as yours, as long as the wood doesn't split, it's good to go.

-

How does she look on the floor? I can't quite make it out what the leg is resting on.

I am thinking just using a steel plate with a hole on a similar vise.

are the jaws 9" across? that is a monster! how much does she weigh?

-

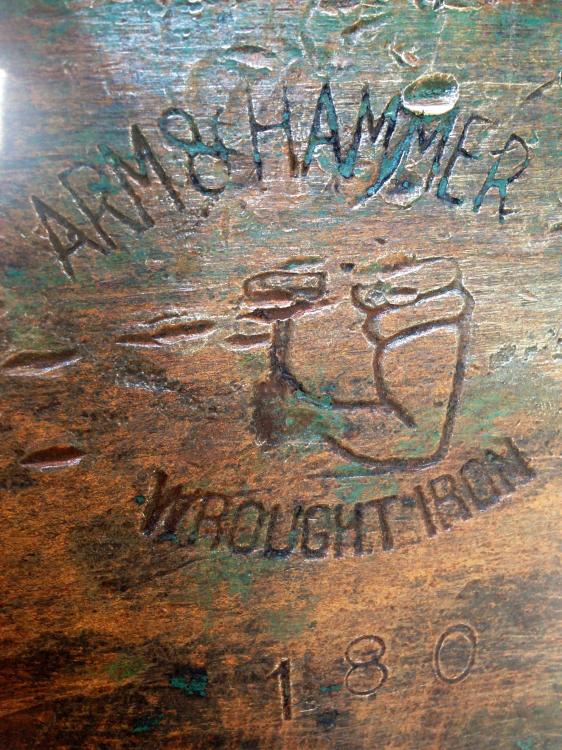

Well guys, I hit the xxxxxx jackpot. I couldn't bring myself to just post it on the "it followed me home" I had t take it a step further.

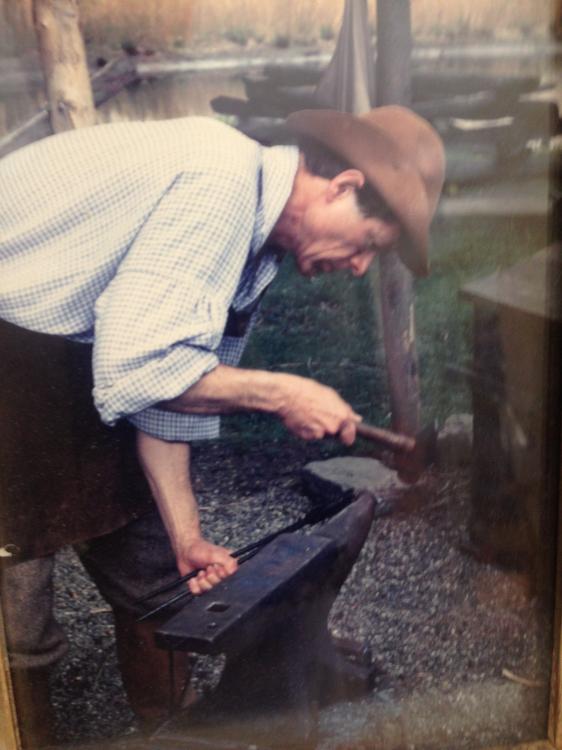

Was at a ranch a guy was selling and I saw this sitting outside next to some trash. he said he was in the process of cleaning up and getting rid of stuff. $50 later and a sore back getting it out of the trunk, I got this gem home.

over a meter in length and 17cm wide jaws (7"?) and the thing weighs over 100#

Since it is so tall I think that I will just make a simple base on the floor (maybe some 1/2' flat stock with a hole to accommodate the foot?) to keep it off the ground and then anchor as usual to a bench. Any mounting suggestions welcome.

Cheers.

-

On 2/26/2018 at 8:26 AM, bluesman7 said:

I do PWS [damascus] by hand very often. A lot of the work can be minimized by making your billets just big enough for the project. Extra material = extra work.

How long it took me to figure out that size matters... lol. All that extra time breaking down stock when getting/buying it closer to spec to begin with would have saved a lot of sweat.

-

On 8/8/2017 at 1:46 PM, lyuv said:

So did I. Until I watched this https://youtu.be/RuCnZClWwpQ

Spoiler - They do make stuff by hitting hot iron on an anvil. But that's the END of it, and the easy part...

If I had the privilage to participate in such a project, the tool made this way would be my most treasured possession.

Now that my friends is a "Rounding hammer" and check out the movable bottom swage, adjusted by the foot. Truly impressive and I love how it is an almost communal activity. Wish we had something like that.

-

On 7/29/2017 at 1:47 AM, Thief_Of_Navarre said:

I like how you make such a vast place sound so cosy. I feel isolated in the UK with only 70-80miles between IFI members :s

Here in my neck of the woods it's only old guys that talk fondly of their old gran that used to smith. they love to come by when i have the fire going and use up all of my "heat time." A neighbour told me recently how they were cleaning out his granddad's garage and found 100s of kilo coal-coke and how heavy it was to take to the dump. Lol.

Off subject i know, but it got me thinking....

Cheers to you guys that live near each other.

-

It aint easy, but I find that it is all in the way we store it. A mountain of scrap can be fine if you had the time to straighten and get the pieces manageable which in turn gets you a nice looking pile of material. But who has time to make the mountain look nice???? Having it all sized and sorted sure does make one want to work though.

-

On 2/11/2016 at 6:59 AM, JHCC said:

"Railroad spike knives are great knives, except for one minor thing, which is that they suck." -- Walter Sorrells

I just had to repost this one because it made my morning coffee squirt out my nose...

-

Worthy of a repeat. That is some sage advice right there. Hell, My forge would still qualify as a Box of dirt that has an old pipe with holes drilled in it.

As Will W. said:

Seriously though, don't get so caught up in the hype that you break the bank. You can do a lot of work and learn a LOT using a section of rail track, a pair of channel locks, a hammer, and a JABOD (just a box of dirt) forge. Check out the overwhelming amount of information on this site, and you'll see that you don't need a 500 pound anvil and a $1000 dollar forge to make beautiful things.

Good luck.

-

Not exactly as the OP originally meant, but I have on occasion leather wrapped a hammer handle to improve size or grip. Done either as a cord wrap or as the Op showed above. Gives a whole other feel and can work in a pinch if you're using a slightly smaller handle.

-

On 10/30/2015 at 5:44 AM, John McPherson said:

Since most of the photos in the old threads have disappeared into the ether, here ya go. Some of the 10,000 or so captured and stored on my system.

Bloody Awesome pics!!!!!!!!

-

-

The Vise to end all Vices.

in Vises

Posted · Edited by Mod34

Excessive quoting

There is no need to quote what we all just read.

Thanks Frosty!

I like the simple plate and lower height idea a lot. There is that slight knob at the end of the foot of the vise which then goes up to some shoulders about an inch above. Is it meant that the "shoulders" support the complete weight of the vise? If so, maybe just cut the correct size hole into the plate on the floor to accommodate the knob at the end of the foot and call it a day? This would bring the height of the jaws to just about knuckle level. What do think?

\Cheers!