Vito

Members-

Posts

74 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Vito

-

Not exactly ''just'' heat treating..

Vito replied to Vito's topic in Anvils, Swage Blocks, and Mandrels

Frosty, thank you for this elaborate answer. Just two things: perimeter welding (with controlled interpass temperatures and cooling down before next side welds) would top out 600celsius of the whole plate? As I have said before; You absolutely need to consider that H11 is capable of resisting temperatures as high as 600celsius before getting to soft for this purpose. I'll probably ditch the plan, as I'm getting ahead of myself, I suppose, and just stick to forging. Although I have been playing with the idea of hardfacing and then machining it flat. That would maybe be a better (and cheaper) option. Again, thank you for the recipe...will definately take it in consideration. Best, Vito -

Not exactly ''just'' heat treating..

Vito replied to Vito's topic in Anvils, Swage Blocks, and Mandrels

Thanks. Best, Vito -

Not exactly ''just'' heat treating..

Vito replied to Vito's topic in Anvils, Swage Blocks, and Mandrels

Charles, thank you for reply. Will look up for high alloy welding rods, maybe that would be a better option, yes. We'll see, but for now I'm sticking with H11 plate for a face, because that's what I have. Thomas, yes, root pass would be done with deep penetration rods (probably 6012). But nevertheless, you can't weld more than the outline of the plate, you know what I mean? Only the outline of the plate can be welded on, you can't weld UNDER the plate, it makes no sense, unless you do as Charles described. It's a hot work tool steel, so temper draw too far is not my concern...you BARELY start touching the temper of this steel at 500celsius, which is about right for welding preheat, so that should be fine. Thank you both. Best, Vito -

Hello everyone, I'm in the middle of the anvil making process. I'm stuck with a big block of mild steel that I wish to properly hard-face it. I have already done that before but with different steel, that's why I'm asking how to do it. I have a 12''x4''x1'' plate of H11, hot work tool steel. I want to weld that plate on top of that mild steel base in order to provide a hard surface. The thing that bothers me is the effect of shrinking/expanding metal during the process. I intend to heat treat that plate PRIOR to welding. I've seen a guy on youtube that welded a plate of 4140 on mild steel block and then he quenched it AFTER welding...I can only imagine that EXTREME stress occured in the weld areas during rapid cooling, but it seemed that everything was fine. Now, do you think that this would work: 1)Do a normalizing phase and thermal cycling, let that plate cool. 2) Heat it up to 1000 celsius, hold, air quench. 3)Preheat the surfaces to be welded, to 500 celsius 4)welding, maintaining preheat temp. throughout the process, cool very slowly when finished to enable hydrogen escape. ? Please, let me know your opinions on this one. Thanks, Vito

-

Oh yes..I sincerely hope that this time the thread is in the right section :/ I really tried to put it in the right section but I just seem not to figure out on where to ask things :/ Mods, please move to the right place if this isn't the correct section. Thank you and all the best,Vito

-

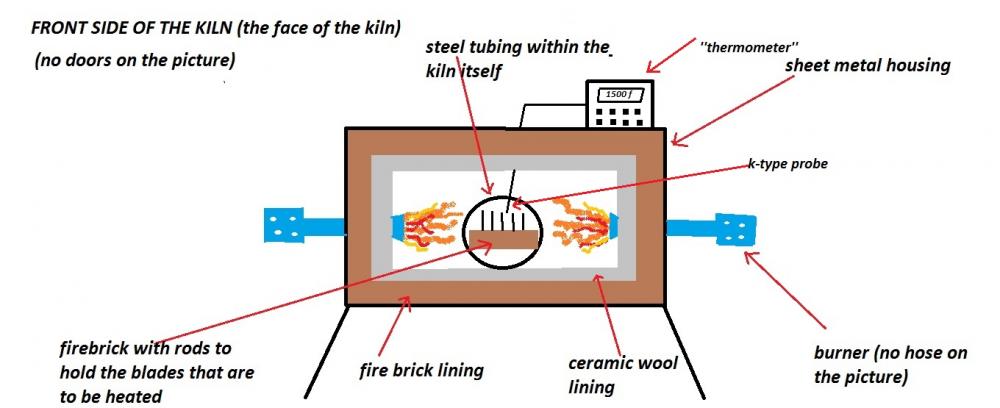

Hello everyone It has been a while since I've last written anything on this forum, which translates to being busy all the time hehe Anyway, I was thinking (already started) of building a gas powered, digitally monitored, heat treating kiln. I want to present you my ideas and post a couple of pictures about the idea itself. Let me know if that ''do-able'' and if I'm going in a right direction For starters, I plan on building a sheet metal housing, from 1/64'' or 1/32'' sheet metal. Overall measurements will be: -aprox. 13'' wide, -aprox. 19'' deep (long) -aprox. 10'' high. After all the welding has been done, I plan to line everything with fire bricks, bind everything together with refractory cement, let it dry and cure. After that, I would line everything with 2'' thick layer of mineral wool and apply ample amounts of rigidizer over that lining. When the kiln main structure will be done, I plan to put in a 6'' dia. tubing in there, to prevent direct flame/centralized heat to touch the blades and enabling only the ''air''/atmosphere to get hot. Inside that tubing, there will be a firebrick, with holes drilled in it and steel rods inserted to hold the blades edge up. That idea with steel tube inside the main structure should work, to enable even temp. for accurate treating right? I'm just not sure about how many burners I should use and where they should be located to ensure the best ''eveness'' of heat and fast temp. climb. Will one burner suffice to EVENLY heat all the atmosphere? Anyway, let me know, what you think Best, Vito

-

Charles, but this topic IS in the bladesmithing section and it IS in the heat treating section and NOT in the ''general blacksmithing'' section. Everything is where it supposed to be. I can't see the problem? Best, Vito

-

Steve...afterall...isn't this a forum called ''Heat treating knives, blades, etc.''? This discussion is in its proper location already. I'm not interested HOW to make a knife. I'm interested in identification and therefore heat treatment of this particular steel... What seems to be the problem? Best, Vito

-

Frosty: I know proper names for heat treatment and if it at some point seemed like I don't then I apologise. But after revision of my own posts I can't find such case. When have I used the word ''temper'' incorrectly? It seems to me like you have missunderstood my messages and not that I don't use terms correctly. I know the terms and what they stand for; everything: from temper colours to differential tempering (that's what you were refering to)....please re-read my posts and you will find out that the word TEMPERING hasn't been out of place one single time. If it has, please feel free to quote me and I will clarify thins up for you. Best, Vito

-

Haha, Charles, I was also thinking of buying a case of beer as a bribe Yes, or I could just cut the main shape a bit angled, so the part with more carbon covers the whole edge; from the plunge to the tip.

-

Thank you, I was thinking alike. Best,Vito

-

Thank you but this file doesn't seem to work properly (again on this forum, like the picture posts) Could you please send me this file to my e-mail? vito.zibert@gmail.com Thanks and all the best, Vito

-

I'm sorry Steve, no pun intended but I'm in a constant rush for a last couple of weeks and spend most of my time in the workshop, in the meantime (when something's curing or cooling or something) I come here and write/ask/reply, etc. This is offcourse no excuse and therefore, I'm sorry. Best, Vito

-

Frosty, that's exactly what I was thinking about. I'm just not completely sure about what tempering cycle should I do after that? Tempering which will suit the core of the sandwich or tempering that will suit the sides of the blade? Charles, I have tried googling that number yes. And this time, was the first time that the google didn't find anything-no results. I will try experimenting with it yes. I've also considered to pay 60€ (about 70-75$) for analisis of the steel because I have unlimited access to that steel and that could pay off in the long run...we'll see. But even with the steel that is only around the teeth, I would still be able to do some decent wood whitling blades, fillet knives, leather cutting tools, scandi knives, etc. The steel that is different from the rest of the blade, is about 20mm wide, which is something like the width of Mora knives... Best, Vito

-

Hello everyone, I have discovered a couple of minutes ago that the saw blades actually are made out of two different steels. The part where the teeth begin and about 20mm upwards towards the spine, the steel sparkles WAY WAY hotter and WHITTER! Where does that lead me? Higher carbon content at the teeth area of the blades? Best, Vito

-

There, I've tested what I've made...and quite honestly, it came out like the thing that comes out when you go on the toilet (can't swear) Long story short...FAIL WAAAY to soft... Something went wrong but I don't know what :/ I'll just keep trying until I get decent result or until I run out of that saw blades hehe Unless one of you comes up with a sensible idea of temperature ranges of individual stages. Thanks and all the best, Vito

-

Ronin, I already have done that...actually that was the first thing that sprung to my mind because doing so would have the most sense. But offcourse...I should have known better...nothing comes free afterall...They said that they can't tell because they have 5 different suppliers and they said that with a tone from which I could presume that they don't want to be bothered with my ''nonsense'' questions. Gergely, yes I'm aware of my ''luckyness'' hehe Well, as you've said. I don't wan't to use the cold stock removal methods, because I have a feeling that this steel is capable of achieving much more. The steel has been treated in a manner which allows maximum toughness and flexibility and not in a manner that a knife should be (harder). Because I will be making mostly small blades out of it (due to thickness), I roughly grinded 85mm long blade, with a rat tail tang, annealed it twice, heated it to non magnetic, hold it there for about 2 or 3 minutes, and quenched it in agitated water. Nothing cracked or anything...now is in the oven at 220celsius. I will leave it there for about an hour and we'll see what happens. Best, Vito

-

M, yes I did. Nothing that could one call a good aproximate. Nothing in particular to find... Thanks, Vito

-

Hello, I recently acquired 5 large saw blades. They're not circular but in a shape of a ''flat sheet metal with teeth on one end''. 2,3mm thick and the blade is made out of one piece (teeth not coated with anything or nothing...). They have been used at local wood processing company and they had to replace it, so I jumped in and without any questions they happily handed me 5 of these blades. Now, that is quite a substantial amount of steel that could prove to be great. The blades have these number etched on them: 5p/8001065-60.1 Could it be that the number 1065 is an identification of the steel? Shouldn't that kind of blade be made out of some kind of high speed steel and not out of simple 1065 steel? I already did the '''quench test''' and after quenching, that piece of steel broke off like steel, with very little effort. The grain at the point of break, was silvery grey, quite fine I must say. Anyway, do you maybe know what could that be? From what steel are those kind of blades mostly made of? I really want to identify that steel because apparently, I can get 5 of those blade every 6 months and I really don't want to pass this up. Thank you for all your help, Vito