emtor

Members-

Posts

44 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by emtor

-

Tried some lathe work today by making a flared choke part from bits and pieces of scrap steel laying around in the shed. I did it mostly to get the feel for the sequence of lathe operations not worrying too much about dimensions. Using plumbing stuff straight from the shelf is a neat thing . . . in the USA,-not so much here on the other side of the pond. Almost everything used for plumbing over there does not exist here and buying from Amazon is a lousy deal thanks to the EU taxing everything that smells american. -So, I'm glad I own a metal lathe and an el cheapo milling machine.

-

Dispensing needles for use in dispensers of some sort (?), not disposable needles (syringes) . . . I get it. I had some trouble finding zirconia until I checked out potter's stores. The blacksmith's community is quite small here contrary to potters so it pays to look in the direction of the clay-people for materials. They sell zirconium silicate powder by the name Zircon 5 here in potter's supply stores. This may be the glaze used for porcelain toilets and sinks I think and would act well as a reflective surface and would also tolerate high temps in a forge. Colloidal silica is everywhere, even at the local paint shop. Bentonite is also easy to obtain at potter's stores. Regarding the parts the book says that call-out sizes isn't always the actual sizes. -Is this also true for the internal diameter of the 1/2 inch burner body which is, according to what I found on google to be closer to 5/8 of an inch?

-

If I choose to go with my propane tank forge,-keep the 2 inch kaowool and keep the depth of 8 inches the diameter would become close to 7 inches instead of only 4. The internal volume would now become close to 300 cubic inches. Now the forge won't be long and thin anymore but more "square-ish", but I imagine that despite a larger volume to heat, the burner(s), as you mention will work better in this situation so hopefully the forge will not become a propane thirsty monster after all. ITC-100 or Plistix is hard to find here in Sweden, but there's always Amazon. By dispensing needles I assume you mean syringe needles.

-

A flame photo won't be neccessary since after reading your(?) book, Gas Burners for Forges, Furnaces, and Kilns,- I will not use the Sievert burner for other than what it is intended for which is obviously not a forge. I found the book after posting my question. And no, I did not stick the burner into the opening. I have a 20 pound propane tank. The cost of refilling it is about 20 USD. The Sievert burner uses 600 grams per hour @2 bar, so in such a setup the propane tank should last 18 hours. With a better burner and a small and well insulated forge it should become even more economical. I only need a forge for heat treating knife blanks and perhaps for forge welding small billets. I started making a forge last summer and I'll continue the work now. It's an old propane tank (20 pounds), and I've already lined it with 2 inches of kaowool blanket and I'll add another 2 inches to make a chamber of 20 cm. (8 inches) deep and a diameter of 10 cm. (4 inches) which should give me 1570 cm3 (96 cubic inches). The fibre blanket will be treated with waterglass solution since I seem to have lost my bottle of rigidizer. Lastly a thin layer of refractory will be added. The refractory is good for 1400 deg. C (2550 deg. F). So, the remaining question will be wether to use the 1/2 inch burner described in your book or the 3/4 inch burner. Avoiding hot spots by using multiple burners are of no concern since I heat treat knife blanks inside a piece of steel tubing which gives an even heat.

-

I've made a small gas forge for heat treating, internal volume=900 cu cm (55 cu inches). I've tried it with the burner that came with the propane tank, a Sievert 2941P, length=75mm (2.95"), diameter=28mm 1.1"), orifice seems to be smaller than 1mm (3/64") possibly as small as 0.5mm (1/64"). It takes a little while to get up to heat treating temp, but once there I can crank down the pressure quite a bit. My question is: -How does this Sievert burner compare to, let's say the Ron Reil burner? The recommended operating pressure for the Sievert burner is 2 bar (29psi) and at this pressure is uses 600 grams/h (21 oz/h) of propane. According to what I read on this forum the diy atmospheric burners built here operate at much lower pressures than 2 bar. Regarding the Ron Reil burner;-is there a minimum forge size that these burners will operate well in?

-

Heat Treating in a propane forge.

emtor replied to emtor's topic in Heat Treating Knives, Blades etc

Yes, that's one way of solving the problem, but I have a small bunch of 1095 equivalent steel and it likes to soak for some time at temp so the steel tubing method allows the knife blank to lay still in the forge without heating up unevenly. I do admire japanese sword smiths that manage to heat the whole length of a sword to an even temp in a charcoal forge. -I'm not quite there yet . . . if ever. -

Up until today I've been heat treating knife blanks in a simple charcoal forge. It's not easy to keep the temperature steady and even harder to keep the tip of the blade at the same temp as the rest of the blade. One trick is to place a piece of steel tubing inside the forge and place the knife blank into that to get a more even temp, but even this doesn't seem to help much since the tip always seems to get way to hot. So, I made a propane forge from a can lined with 2 inches of ceramic fibre blanket treated with waterglass and a thin layer of refractory. The burner is just the burner that came with my propane tank and the 2 bar adjustable pressure regulator. Rumour has it that its hard to keep a knife blank steady at the desired temp inside a propane forge. Today I tested with a piece of steel tubing inside the forge. After ten minutes the steel tubing was glowing along its full length with a color indicating about 800 deg.C (1472F). Then I inserted the knife blank (1095) and adjusted the gas flow till the knife got to non-magnetic and then some, and then I let it soak for five minutes. The blade was at a very even temp along its entire length including the very tip. Quenched in oil and tested with a file. File skated across the edge and then I broke off the tip and examined the grain structure. The knife blank was glass hard and the grain structure was very even and fine which indicates the temp was high enough to harden the steel but not so high as to cause grain growth. So, yes,-it's seems to be possible to control the temp in a propane forge within reasonable limits.

-

Newton's third law . . . action / reaction. I think the college 101 physics class would use this law. If you sit in a chair, your body will exert force on the chair (from above),-and the chair will exert the same force on your body (from below). In our case, a piece of steel between a hammer and an anvil will be hit by two forces;-one from the hammer and one from the anvil according to Newton. If this has anything to do with anvil hardness,-I don't know. Let the 101 physics figure it out.

-

Well,- THIS video link removed due to language on Youtube claims just that . . . anvil rebound is horse xxxx. The video further says that blacksmiths prefer anvils with a good rebound because it makes the hammer jump back up and therefore saves energy for the blacksmith's arm. In my opinion (I might be wrong), rebound has to do with Isaac Newton, and that any action produces an equal reaction. So, when the hammer hits the workpiece from the top, an anvil with good rebound will hit the workpiece back from the surface of the anvil with a force depending on the rebound. Now,-is it true that rebound is of no value in an anvil, and should I trust Isaac Newton or the xxxxxxxxxxxxxxx on Youtube? BTW,-both my Swedish anvils have rebound a bit above 90%.

-

Soderfors is a really small place with less than 2000 inhabitants, which is typical for Sweden's industrial policy. Locate industry in places where people otherwise would move away from. My other anvil is a Lesjofors, another mini town with less than 1200 inhabitants. The common feature of these places is a river, a fast running one, to produce the power needed, hence the suffix -fors in the names (fors=waterfall). So, if you end up in a town with a name ending with -fors, be sure it was or still is an industrial town producing items that require steel as a raw material. For people like us Sweden is "the land of milk and honey", or should I say, the land of second hand anvils, tongs, lathes and milling machines and any other steel item.

-

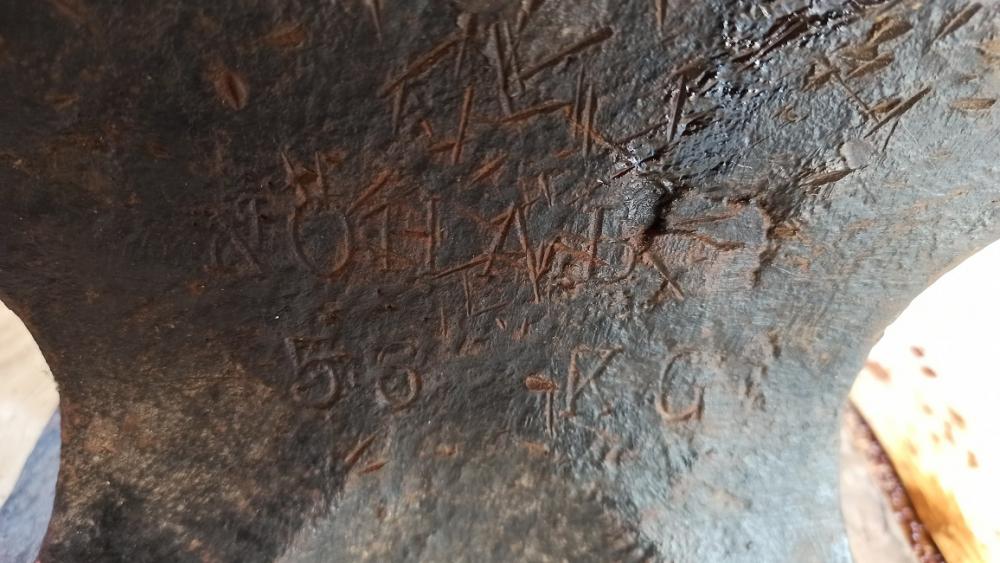

It's a Nohab anvil. Nohab of Trollhättan, Sweden, startet manufacturing in 1847, producing locomotives, hydropower turbines and tank chassis and obviously anvils. Weight: 56 kilos. The anvil appears as almost unused and rings loudly like a bell when struck lightly with a hammer. Now,-it looks like it has a steel plate forge welded on the face. -Maybe it has, maybe not, but cast steel anvils usually has the name of the manufacturer protruding outwards. This anvil has the name and weight chiseled into the metal. -Perhaps it's a forged anvil with a tool-steel faceplate welded onto it. The face is flat with only a couple of very small scars. The edges are undamaged and a very small portion on one side is sligthly rounded. I'm not selling this . . . ever!

-

Thanks Frosty, It makes sense.

-

I'm not sure about the weight, but it is smaller than my 80 kg Lesjöfors anvil. The vise weighs 20 kg. I'll take some more pics, hopefully tomorrow. -I need to buy some chalk too. I haven't really looked at it yet. Been busy adding a concrete floor and insulating my old shed.

-

Came across this one today,-an old Swedish anvil, can't remember the brand. Look closely, it has a thick toolsteel face forgewelded onto it, no dings, cracks or wounds on the face and the edges are without blemishes. The face is very smooth and flat, I consider myself lucky. The seller had several anvils for sale but this one was the nicest of the lot. Oh BTW,-I bought a blacksmith's vise also.

-

I've tried welding a piece of high carbon steel to a rod of unknown steel once. -Should have known better,-the weld cracked a few days later. -Never again.

-

I don't know much about anvils either, but I know they can be cast iron (cheap and not very good), cast steel, soft iron with a tool-steel face etc. Different anvils would require different methods of repair. A welder working in a shipyard may only weld low-carbon steel in his or her lifetime and may know nothing about hardening and tempering higher carbon/tool-steel.

-

Cooling down is critical since the base metal and the weld will shrink at different rates. Too fast, and the welds will crack. I once tried to weld cast iron with nickel rod, which should be just fine. It cracked due to the fact that I didn't preheat, and let it cool down without insulating.

-

I know that many reface their anvils by welding, and it's OK as long as they follow the rules. Preheating, correct rod that goes well with the base metal etc. I'm not a welder by any stretch so I'll use the anvil as it is. There's a video on YT where some guys are heating an anvil up to hardening temp and then dropping it in a barrel of oil. -Not for the faint of heart.

-

I'm a Norwegian expat presently living in the north of Sweden. Sweden is nice since it used to be an industrial nation, so there are loads of machines and equipment hiding in garages and barns to be had for cheap. Swedish stuff by the way, is of very high quality. -I like it here. I'm not sure I understand the question. -What I'm planning to make, or what I'm able to make (on an anvil)? I make knives (stock removal method), so for doing that I really don't need an anvil, but it would be nice to be able to make chisels, drifts, candleholders etc. and for that the anvil will come in handy.

-

As I said,-there is an air hardening tool steel welding rod to be had, but I do not know if this rod would match well with the steel in the anvil. And if not, the anvil would be ruined, so I won't take that chance. I'll start using the anvil as it is.

-

Robb Gunther's method requires heating the anvil to 400 F before welding, but there exists a welding rod made from air hardening tool steel (Selectrode 1256) that do not require the base metal to be heated up. Hardness when untempered is 55-60 HRC. But, it all depends on wether this rod welds well to the base material or not. If it does, all is well,-if not, the anvil is ruined.

-

I wonder what could have caused the damage. A chisel will raise a lip, but the marks on this one looks similar to what you would see if a grinder with a thin cut-off wheel was used so there's nothing to planish. Yes, it has been mistreated badly, and it makes me wonder what could have caused it. However, the old anvil has been rescued from the grave and will give years of service still.

-

I'll follow the advice given here then,- I'll do nothing. I've been looking for an anvil for years, and now I've got one 121 years of age. Would be a shame to ruin it.

-

All of you are quite correct, not a good idea to remove the hardened face. -No idea how deep the hardening goes. Would filling the dings with weld (stoody 2110 rods) be a better idea and then grind flat with a flap disk? Doing nothing at all would still make the anvil quite usable though.

-

Picked up an old Swedish anvil, made by Lesjofors Bruk, Sweden in 1899. -Weight: 181 pounds. Lots of dings in the face, no cracks, rings like a bell, very loud and the sound seems to last forever. Lesjofors anvils from this era have a reputation of being of high quality. I cleaned up the face somewhat with a flapdisk but a couple of the dings were a bit deep so I'll take it to a machine shop and let them mill the face. It seems that the steel develops a patina instead of rusting.