-

Posts

274 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by angiolino

-

-

thanks for the tip, I think I have to find a system for ballasting to level the blade share

, the depth of cuts and the advance otherwise brings me to the crooked floor and the bumpy path is not on the flat, if it takes a large stone it clings the bucket creating damage, thanks anyway for the suggestion. maybe instead of a hydraulic lifting system I put pulleys or a hoist or winch device, I have to think about it.pull dozer Tow behind road grader

-

this would be the tractor, how would you build it? practically it would be like the bucket the blade of a bulldozer.

maybe with a schematic, how much I regulate, thanks. it would be like a towed plow-

-

hello, sorry if I disturb a friend of mine would like me to build a box blade gannon, it is an agricultural tool that is towed like a plow a ripper that is used to fix the dirt roads is like a skip loader, some suggestions thanks

-

-

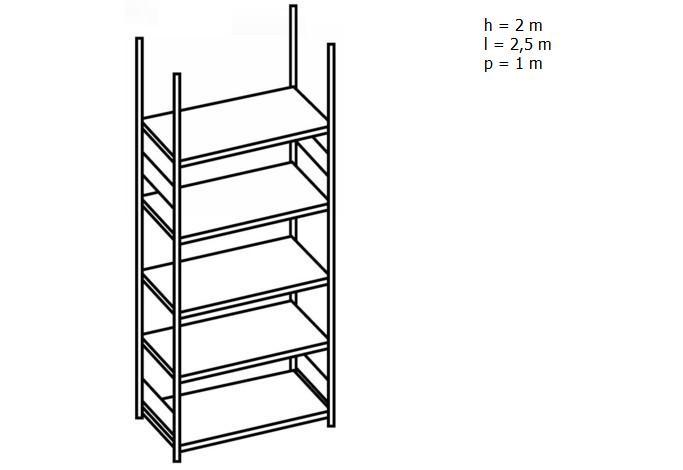

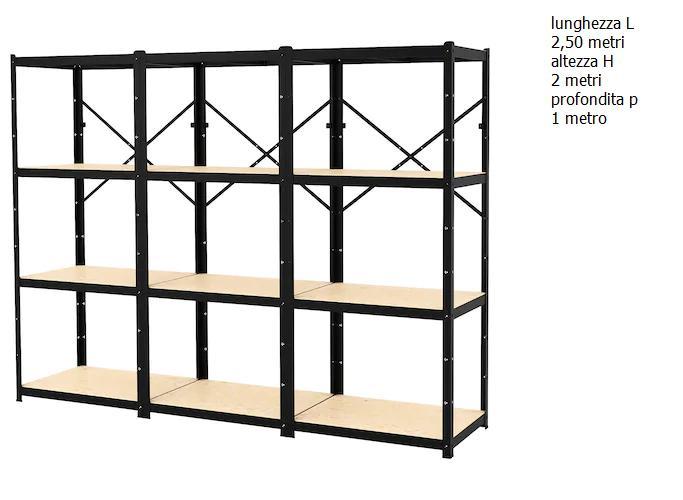

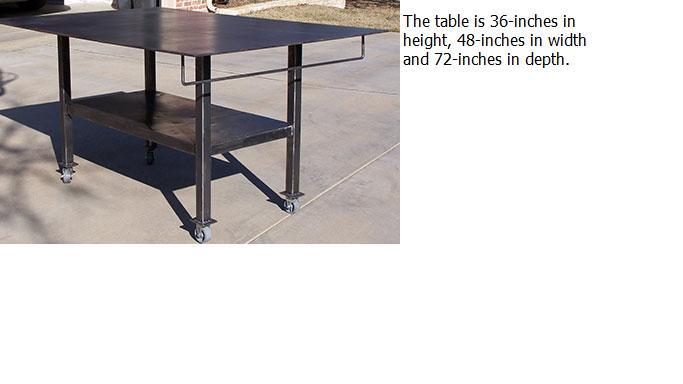

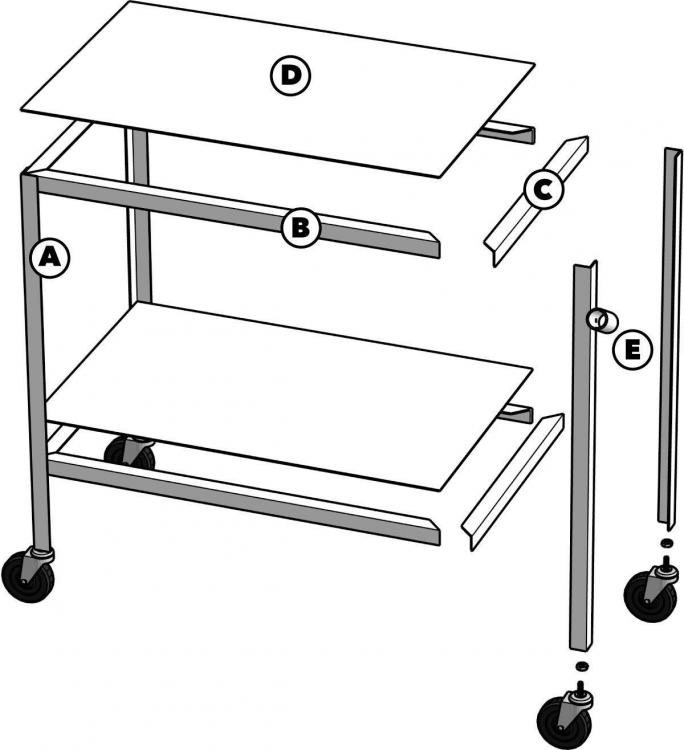

thanks for your valuable suggestions, the wheels cannot be placed due to a question of stability, I have to store heavy objects, but I believe that in the middle shelf that I will put at about 80 cm I will bolt a vice and I will use the same as a service counter to perform chores repair and I will equip it with suitable tools thanks

-

thanks for your valuable suggestions, sorry if I disturbed you with my question

-

sorry if I disturb, I should make a big one

metal shelf to put my shop in order, I need a very heavy and robust structure, a shelf that I want to make about ninety centimeters high, it will serve as a service counter. some ideas to take as inspiration. what material do i use? dimensions two meters long, two meters wide one meter deep, it should support several quintals and be economic in construction. maybe coin recycled materials, let me know thanks greetings to all -

make a virtue of necessity. the need sharpens the ingenuity, we don't make grilled sausages and steaks, we eat baked pasta, parmesan cutlets brought from home, contained in bundles brought from home that's why bundles, bundles that contain food like sack breakfast. all the original Italians, especially the Neapolitans, experts in the art of getting by with little they have and lots of imagination and inventiveness

https://youtu.be/85vtAPZPK2U

https://youtu.be/HaKi7oeYZEo

The Ottoman and Balkan yataghan sword/knife

https://steemit.com/crafty/@elvis.stepcic/a-blade-from-a-not-so-far-past-meets-my-wild-idea-and-so-a-hybrid-is-born-indigo-recurve-yatagan

-

pic nic , scampagnata

in the Roman dialect the people who make the picnic call them "fagottari" they bring the food cooked from home and make revel

-

thanks for the right suggestions, unfortunately I live in the suburbs, you understand that I can't emit combustion fumes, my neighbors, too close to each other, would complain or worse, they would report me to the authorities in charge. , first I went to my uncle who had a mechanical workshop, around me parts of the blacksmiths no longer use the classic coal forge even with gas, now they buy the iron bars and the elements already forged and stamped by the factory, segmantano the they assemble and weld, from blacksmiths they have evolved into welders, they don't even have a blowtorch flame, I have to find an ingenious DIY solution that is home-made and safe and cheap to manage. thanks anyway for the right suggestions. I have to investigate heat treatments, temper annealing, nitriding cementation. Thanks again

-

thanks for the valuable advice. I have a modest equipment, like steel I use the elliptical sheets of old truck springs, I don't have a forge I have to find a way to make up for it with foirtuna equipment thanks again sorry for the trouble, thank you ..

-

I did not use the ax with the iron pipe as time passes, I use the one with the yellow handle and the machete to clean the garden of shrubs from bushes that form spontaneously. I had to interrupt the construction of blades. before I went to my uncle who had a machine shop with machine tools and equipment, since he died and the workshop is closed I built a small workshop in my house, but I don't have the comforts of a mechanical workshop. I have a banquet and some tools, so the results are modest. I can't shoot the blades on the anvil. I just cut out the shapes of the blades on sheet metal cuttings and then sharpen and polish them. therefore the result is modest. thanks for the right suggestions

-

-

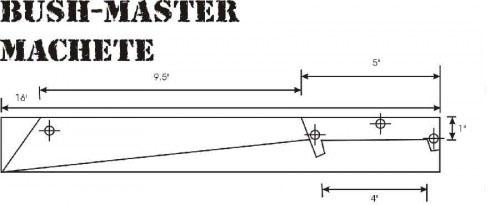

I tried to make a machete with a crossbow sheet truck it is very rudimentary and rustic I use it to clean up the soil from the bushy bushes shrubs. I can't make the ergonomic handle ... thanks anyway

-

hello I would like to try my hand at building a knife. I thought of a kukri I think originally from Nepal or a Yatagan, of Russian origin I think, you would kindly have pictures or drawings, what material do you advise me to use, have some friend friends built these specimens? I just a few rudimentary machetes. if I can I would like to make a big bowie knife later, which they tell me is an indestructible knife. thanks

-

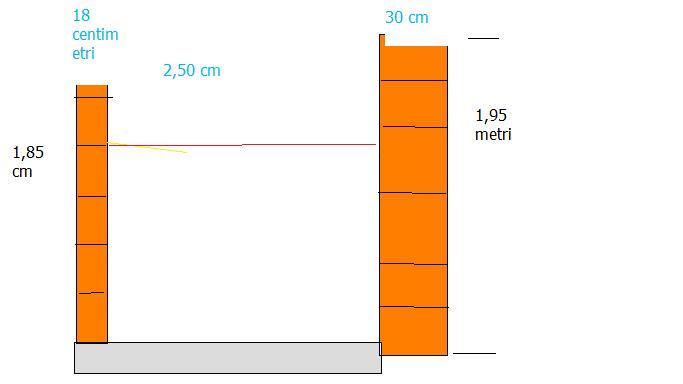

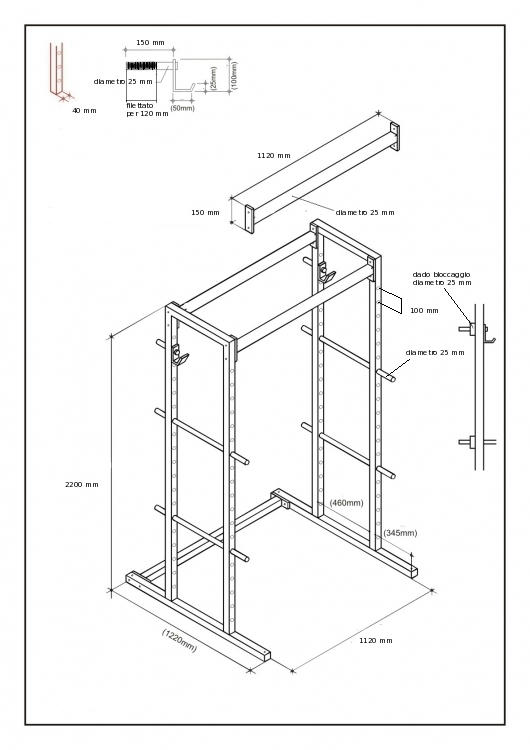

the whole place is 3.70 meters, calculates that I am 180 cm tall therefore, the walls are weak, I would like to find simple robust and cheap materials, maybe scaffolding pipes, what do you say how would you do spending a little money, but realizing a robust structure ? thanks for your opinion

http://minamishika.com/tubi-innocenti-bricoman.html

-

hello I should make an internal mezzanine in my shop, I have two parallel brick walls I would like to place on it the beams on which to apply the platform.

wall dimensions: a wall is 2.20 meters long, 1.95 meters high and 30 centimeters wall thickness

the second wall is 1.85 meters high and 18 centimeters thick, the distance between the walls or width is 2.50 meters, as I realize that I use material, that load and capacity I could load on it thanks ... -

thanks for your advice I found 80 cm x 40 cm boards you think it is enough L-shaped iron from 30 mm height 90 cm from the ground 3 shelves.

Required Materials

1/8" standard steel angle iron (sizes chosen to accommodate 4-foot lengths angle iron is available in):

Four 1/8" x 1" x 1" - 18" in length mitered at 45 degrees

Four 1/8" x 1" x 1" - 30" in length mitered at 45 degrees

Four 1/8" x 1-1/4" x 1-1/4" - 36" in length (legs)

Two 1/8" thick mild steel plates measuring 17-1/2" x 29-1/2"

Four casters with threaded shafts and matching nuts

Four coupler nuts used to fasten threaded rod together

Four lock washers to fit caster shafts

One steel tubing 3" in length, 1-1/4" inside diameterMaterials List

- 1-1/4″ x 1-1/4″ x 1/8″ x 10′ angle iron (3)

- 32″ x 20″ x 1/8″ sheet metal (2)

- 1-1/2″ x 1/8″ x 4″ round tube (1)

- 4″ x 130-lb.-rated caster with brake (4)

- 7/16″ non-zinc or galvanized nuts, fit to casters (4)

-

welding cart

hello, I should make a small table with ruoote to put on a synergic welder the measures are 170x 320x 400 mm the weight six kg should be at least 80/90 centimeters high from the ground with all the wheels, I would like to create a welder trolley on which to make even shelves like shelves to keep the welding machine, the mask the cables the electrode packs and all the necessary equipment, some economic and aesthetically pleasing ideas to lose little time and little money thanks

Commercial link removed.

-

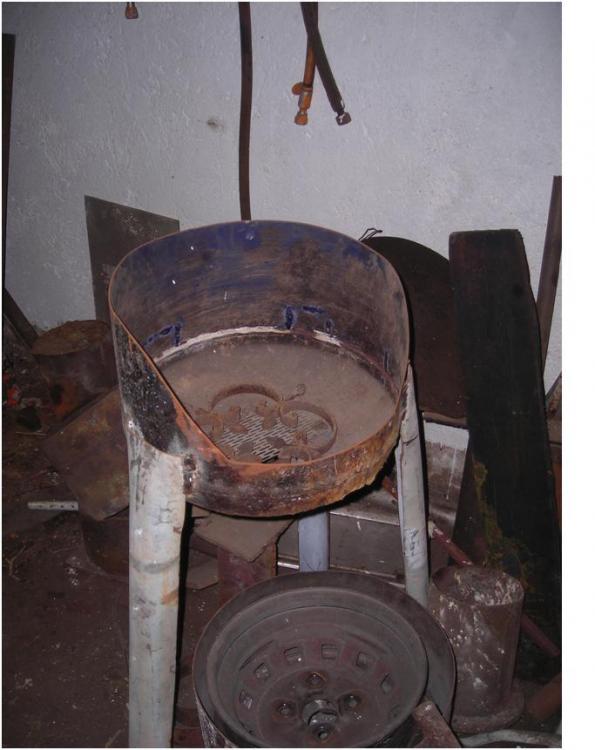

I should add the bellows, thanks for everything, if maybe you would do me the favor of attaching some image you would do me a great favor, thanks again, sorry if I disturbed you thanks

-

sorry could you be clearer, maybe with picture or drawing what should I do to make it usable? sorry if I have an insight, a picture is worth + 100 words thanks for your availability. maybe link me to a picture or similar discussion, thanks again, I'm sorry if I'm boring and repetitive

-

-

hello I would like to build a homemade forge with recycled materials, I recycled the container of an old electric water heater, how do you advise me to make it? better to gas or to firewood type brazier. do I have both a gas torch to weld the tarry sheath and a large gas stove? do you need refractory bricks as you advise me to proceed? thanks

-

thank you sorry if I take advantage of your patience and your precious time thank you again, I'm too fussy and boring forgive me.

thank you sorry if I take advantage of your patience and your precious time thank you again, I'm too fussy and boring forgive me.

Halligan_bar homemade

in Tools, general discussion

Posted

https://en.wikipedia.org/wiki/Halligan_bar#/media/File:Pick_adz.jpg

hi, I would like to make this fire brigade tool, could you help me, how would you do it? thanks