setlab

-

Posts

199 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by setlab

-

-

Well you don't seem that busy if you're surfing iforge... Just saying

-

Not really a problem, why not ask a Smith with a similar hammer than bother a busy guy?

-

So I'm in the process of changing my 30wt oil out for 10wt oil in my 33lb anyang and am just letting the oiler drip on full blast to empty it. Before I go chipping all the paint off the oilers bottom in search of a drain, Is there a set screw on the bottom of these oilers to quickly drain all the oil?

-

All torque from a #6 should be close to the same no? But it's a deep throat Norton. I don't think it will twist the table legs out of square, but all the fly press tables Ive seen are pretty heavy duty.

-

I'm building a stand for my #6 flypress and am wondering if I'm building it to light duty. Looking at my steel pile, I have a bunch of 4"x4"x1/8" square tube for the leg columns/bracing and some 1/4" plate steel for the top of the stand, I plan on having 3 or 4 legs bolted to the floor. Will those 4x4 legs probably keep up the the flypresses torqe without distorting?

-

They look simple enough to make

-

-

I'll see if I can hold my phone and hold my tongs at the same time for a video. The treadle isn't hard to push, it just takes a lot of trial and error to maintain a slow and steady hammer rhythm. Seems like there's this very small window to play with and once you're out of it it's hard to find again. I have no idea how to calculate the blows per minute, I imagine that's a pretty long math equation. What is tup, hammer to anvil ratio? The ram head minus the hammer dies weights 50lbs and it's a 6" solid round anvil.

It's probably wishful thinking on my part to slow it down to my skill level of smithing. One of those things I have to do more often I suppose.

-

I've been useing it for about a year now and while it's really nice to have it just doesn't have the control and steady rhythm I've seen on other hammers, mostly air hammers come to think of it. My hammer seems to only have one mode, hit hard and very fast. It's kind of difficult to find the right balance between foot control and how fast the hammer hits, it's hard to hit lightly. What can I do to slow this beast down a little? Besides the ram that is adjustable height I built it following the directions pretty closely. So far I've adjusted the tire pressure down some and it's given me a little more control but not too much. Can you put a variable speed control switch on a standard single phase 110v motor?

-

Where is a good place to buy some various sizes?

-

Oh wow, your google skills are much better than mine lol. After a little spit polish on the tag mine is a 5x5 too, it looked like a 3 earlier. That is the same saw though. Almost a shame to do it but I plan to put a nice coat of paint on it and put it in my living room.

-

-

-

The blade is 14.5" long. Defiantly will be taking some pictures when I get home within a week or so. I originally thought it was for really thick stock but 3x5 is hardly thick by any means, maybe it was made for an application where the cuts needed to be as parallel to the ground as possible?

-

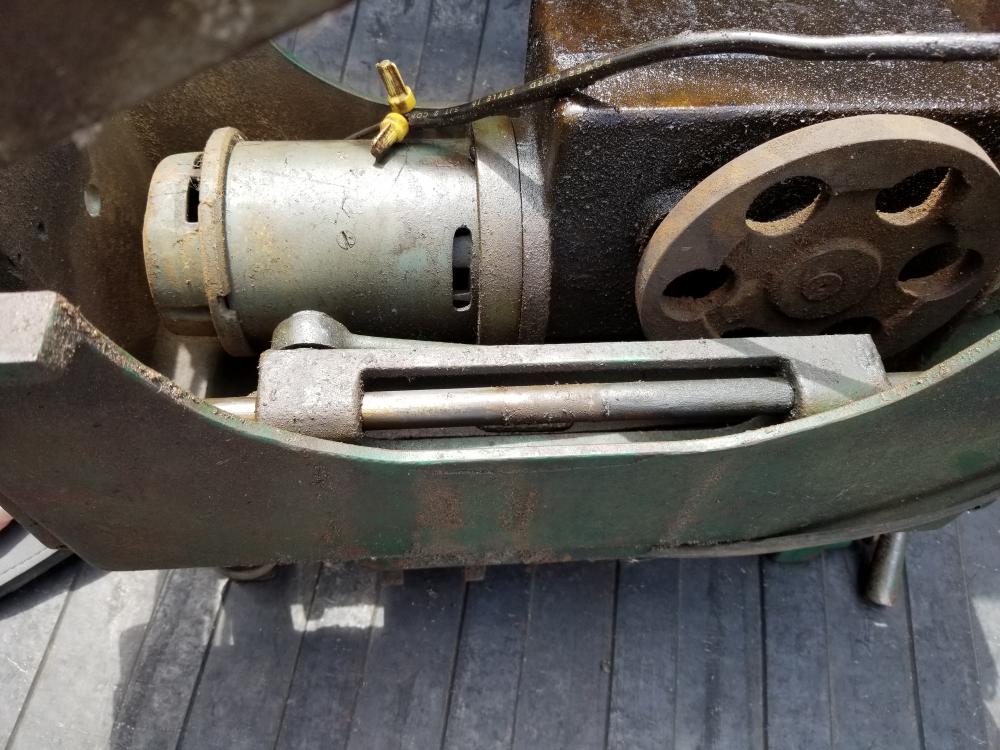

So I found this little guy today and brought it home, thought it would look pretty neat with a fresh coat of paint on it. Has anyone ever seen one like this? I did a Google search but so far no luck on any information out there on it. It was made by Louisville electric manufacturering company, no. 26065 type CD 3x5 capacity 90 rpm.

-

Awesome thanks!

-

My leftover can of itc100 has dried out onto a brick. Can I pour a little water in it again to reuse or is this stuff pretty much done with?

-

Luckily it's not going to take but a few minutes to make another. I think i'm going to keep this one to hang on my wall of mess ups instead of salvageing it.

I went back and spark tested it and it does look quite a lot like cast metal.

-

Haven't spark tested it yet.

-

-

Has anyone used the new dewalt flex volt angle grinder? I've been eyeing them for a long while now

-

How do you guys that make your own drifts end up with the final dimensions? Do you just aim for a squareish oval shape and call it a day or are you going for a specific dimension?

-

A concern I have is the quality of the welding that will go into it. Before I built a power hammer, I read and searched for every hammer group build out there and a some of them left me a little wide eyed from the atrocious welds. I'm far from a professional welder myself but from everything I've read on building Forging presses weld quality is a pretty big safety issue.

-

What part of the state do you guys meet in? I would definitely be interested in joining your build if the costs are in your ballpark estimate range. I wouldn't have an idea how to do it besides following Jim Batons book though.

Anyang hammer oiler drain

in Power Hammers, Treadle Hammers, Olivers

Posted

Amen, I love this place. Just wish people who didn't want to reply didn't chime in stating that fact. Lots to learn just by reading.