-

Posts

1,056 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by Gergely

-

-

-

If it's dead flat or flat-ish it would be a killing planishing table. With all those rectangular holes in it for tooling... man! Just some heavy legs under it and you're golden.

That's what popped in my mind anyway.

Bests:

Gergely

-

Congrats James! Nice blades, very nice. Always like to see your works. What's length of the parangs?

Bests to you!

Gergely

-

JHCC Wow, nice piece! I found two similar shaped knives from Nigeria at the https://anthro.amnh.org/collections which is my nr1 place to look for African tribal objects. But yours represents very sophisticated lines and style.

I own several edged weapons from the Central-African region and after looking, touching them closely and trying to reproduce some of them I can tell the same: those smiths there really knew their job. The rustic and "primitive" lines of the old ironworks are often made with such precision and care that no shame if you can't get it done yourself.

Bests:

Gergely

I'm on holiday now, but the parangs' epoxy curing while we're having fun

.

.

-

Hi,

I'm a bit behind with it but, JHCC I really like your African inspired ring handle knife. Is its original from Cameroon? - Or have you got more info about it? I tried to search for something like that and found almost similar shapes but I'd like to know more. (While searching I happened to run into a very inspirational shape of a wooden knife, that I will try to forge sometimes.)

Thank you ausfire ! Just got the response from the buyer, they love them - what else can one need to hear.

I was thinking maybe a thinner lined oval for the hood rings on the cobra, I'm not sure if deeper cut will do better - but we'll see, won't we

I very much like your snakes, too.

I very much like your snakes, too.

About work: Yesterday I had to forge a Chinese made masonry hammer into an electrician's small pick axe. It was not fun... Especially when I tried to quench it in oil and it didn't harden, then quenched it in water and it cracked. A bit more work to do, but doesn't matter - got it done anyways. I had to make another e. pick axe from scratch, and it was easier and quicker to get ready.

Also preground and HTed two parangs with over 10" blades - now that was fun! Also HT-ed my first pieces of the Rollerblades series: one bearing roller forged into two knives.

No picts this time, but soon...

Bests:

Gergely

-

Made these hairpins from upcycled materials: pins are forged copper, and the straps are pieces of a leather belt of the last transmision belt driven wheat mill in Hungary. Put the pictures and info on my FB site, and both of them were sold right away. - Now I have to make new ones... Oh, the sufferings I bear...

Bests to all of you!

Gergely

-

Also using a smaller hammer with a bit "sharper" peen might help a bit, too.

Bests:

Gergely

-

I hope you feel better already, Frosty. Take care and heal!

Bests:

Gergely

-

Beautifully executed!

Bests:

Gergely

-

Ranchmanben -

That's real nice work, Ben!

If I may suggest: shorten the cutter tool for the power hammer. A tool that tall can be very dangerous. You don't need more height than 1 1/2" - you can cut through 3" thick bar with it.

I use this one, it's made of the equivalent of AISI L6 hot working tool steel, it's 30mm (1 1/4") tall:

John Rigoni has a great video on youtube about the how to.

Bests:

Gergely

-

JHCC -

Oh, yes. And even the ones with all the education!

Craft fair dialogue:

C: -What these things are?

Me: - These are key fobs with the signs of our old runic alphabet on them. (Showing the writing at the board.)

C: - Ooh! I see. So these mean something?

Me: - Yes. These mean the letters of the old alphabet.

C: - Ooh, I see! Is there any system in these if want to find one?

Child standing nearby: - Yes, dad/mom, there are the letters of the alphabet...

I don't blame anyone though, there are so much to see in the world...

-

Thank you, Aus!

These are made of very fine grain WI, it usually forges almost like old mild steel. I do forge them at higher heat and stop it in time. The only problem I face sometimes is when the stock has some greater inner delamination - like the line showing at pic1. It can mean defection that is not worth repairing. But like in this case it's not always fatal.

Yeah, I sell these, people like to hear about the old harrow story. My "business name" refers also to recycling, so I do keep telling these stories over and over and over...

I'm thinking about labels attached to items, but people tend to not read signs and writings around here.

I'm thinking about labels attached to items, but people tend to not read signs and writings around here.

Bests:

Gergely

-

Hi Aus,

If you want to use it for hot punching you don't need very exact tempering - the first dip in the orange hot stock is ruining all heat treating at the business end.

If I were you and if it is a hot use tool, I'd just put its business end tip back in the fire for a short time (~10 sec in a normal coal fire). It gives some ease for the steel, and then the first punching job will do the rest.

Bests:

Gergely

-

-

-

Awesome, thank you!

Bests:

Gergely

-

I like it very much, Ben! Nicely grained wood with beautiful color, simple but yet elegantly decorative steel parts. And nicely welded for sure!

Bests:

Gergely

-

On 1/28/2018 at 10:06 AM, JHCC said:

I’m particularly happy about these two seams (although the dogs seem somewhat less impressed):

Yepp, those were the ones that caught my eyes in an earlier picture.

20 hours ago, jlpservicesinc said:That is one of the most likely places to get a crack.. One of things that took me a lot of years to learn is. " Cracks happen in many places while forging, 90's, bosses, shoulders, etc, etc.. Difference between a good piece and a bad one is watching out for these kinds of things.. You'd be surprised just how many forgings have forging cracks or cold shuts..

I have a factory made axe of the same style, and it has small cracks in the very same place, too. Now I may know how it got them... (or not

)

)

Bests:

Gergely

-

5 hours ago, jlpservicesinc said:

I don't know where this is going but there is a cold shut in the corner.. I imagine you will be grinding it out??? I'm also sure I had no reason to point it out as I'm sure you had seen it and all ready had a plan to deal with it..

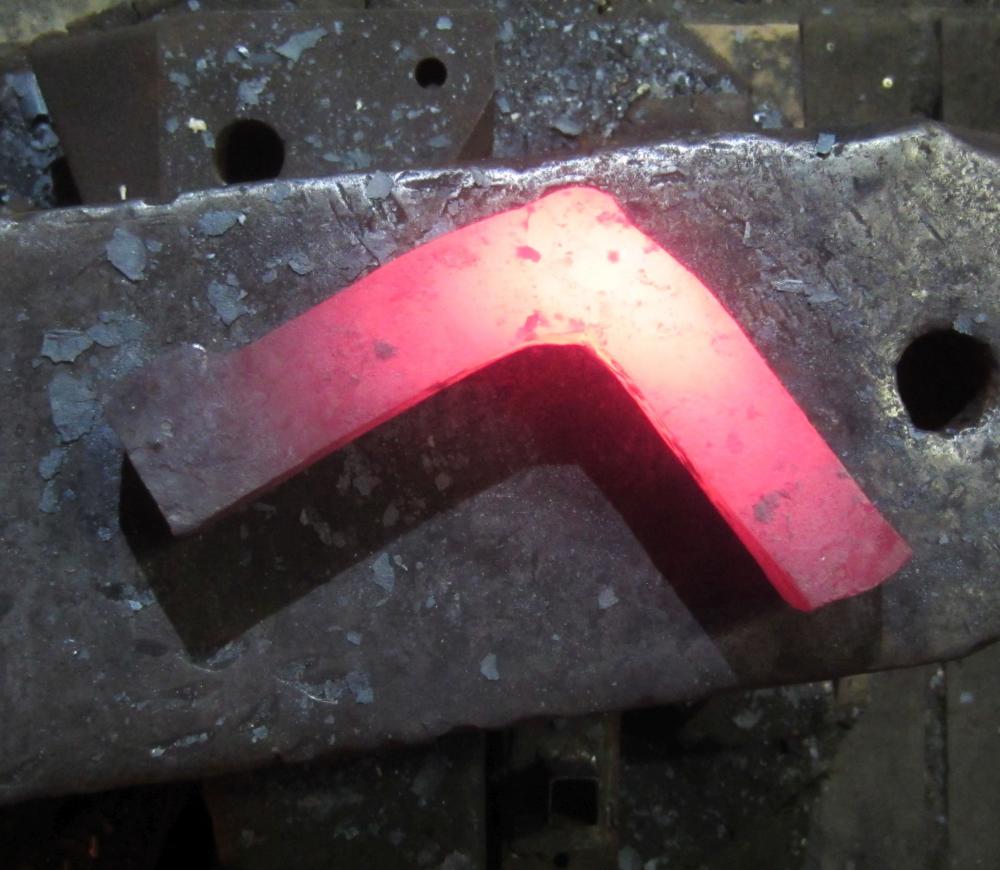

It's a cold shut, you're right! I've seen it and thought: how on earth got it a crack there?! But it's actually coming from the bending not from some cracking force. - Thank you!!

And yes of course it has to go.

Bests:

Gergely

-

@JHCC

That happens more often then one could imagine... There are some seams around the pivot that are pretty nice - you're really getting better continously. If you don't mind though I think when you welded the long seam holding together the angle iron and the base plate you either welded it too fast or with too low amperage. Also a bit more surface cleaning can help a lot.

That happens more often then one could imagine... There are some seams around the pivot that are pretty nice - you're really getting better continously. If you don't mind though I think when you welded the long seam holding together the angle iron and the base plate you either welded it too fast or with too low amperage. Also a bit more surface cleaning can help a lot.

@Origins of Iron I like that tripod and trammel very much!

I only had short time in the shop. Was fighting with a 1,5 kg / 3,3 lbs piece of 1045 trying to make it into a bearded axe. Not even halfway there but so far I got this time. My coal is so poor quality now that it makes everything very painful, finally I lost my patience and let it be. Also one of my main power hammer tools got broken. Been less nervous

Today, hopefully I can continue, repair and make new tools. On monday I'm getting better coal, too.

Today, hopefully I can continue, repair and make new tools. On monday I'm getting better coal, too.

Bests:

Gergely

-

Hanging by the axe making feeling: made an axe drift and a portable hole for the drift.

The drift was forged from an old railway wagon axle - ~2" dia and the starting stock was 3' long. I cut it to size only after forging the handle part of the drift. The second picture shows the bigger half resting on the 450lbs anvil (not bragging, just. size reference

)

)

Bests:

Gergely

-

Thank you, Guys! Hopefully today brings another one, will see...

Some people just want to do it the hard way, eh, Das?

Bests:

Gergely

-

-

Hi bigb,

You're trying pretty similar sparking stuff. If you want to work with scrap try to compare these: 1. piece of smaller angle iron - sure structural mild steel. 2. piece of leaf spring - almost sure 5160 type medium carbon low alloy. 3. piece of ball bearing - almost sure 52100, 1.0% high carbon steel.

Also I use an angle grinder with the thinnest cutting disc. Works for me. But I gave up to try identify steels this way elsewhere than in my own shop.

Bests:

Gergely

MIG problems

in Welding/Fab General Discussion

Posted

Hi Aus,

It can't hurt to look after the gas thing. Although those blobs look like they were shielded all right so the gas did its work. To me also it looks like there is some main configuration problem with the machine. I think Marc and Biggun got into the heart of the trouble. (BTW I use a machine something like yours at everyday basis, you can mess up the very simple config, if you switch the timing/spot/continous/normal functions by mistake.)

Bests and good luck:

Gergely