-

Posts

1,616 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by Nobody Special

-

-

What a pretty little Trenton, and in California too. You must have lived a good, clean, wholesome life. My second thought was that somebody didn't love it very much. Too much cold work on it, left all those little rings and wallowed out the hardy hole some. Looks like you cleaned up some mushrooming too, and they got welding spatter on the feet. Poor little guy. Fortunately Trentons will take some abuse if it's not applied wholesale. Keep it warm and feed it lots of hot metal daily until it feels better. Nice find.

-

Fair enough, what's one more Ancient One? And besides, careers in advanced electric trends towards the mystical, eldritch, and devolved anyways.

What was the original question again?

-

You clean the parts to be joined, very very clean. Then you heat to about cherry red, take a fast pass with the scale brush, and add copper, brass, bronze, or whatever you're joining it with. You can use other non-ferrous metals, but copper or brass works fine is tough, and takes some heat. You will likely want to wire it together before the initial heat so that they're held in place together. Anywho, rambling a bit. Add your non-ferrous metal, a bit of flattened pipe, wire, or brazing rod, and put it back in the fire until it melts and joins the pieces.

I've seen it done with brass powder, but never tried it. And you may want borax as a flux, copper oxidizes easily when it's hot and doesn't like to flow. Someone correct me if I'm wrong, or my technique is off, I've done it a few times, but I did more forge welding than brazing, and no brazing in a few years.

-

10 hours ago, ThomasPowers said:

And the Great Old Ones have such trouble finding architects these days! Though I hear the codes in R'lyeh are interesting to say the least!

I'm not about to complain. If Yog Sothoth and the Goat with a Thousand Young don't insist on GFCIs, then I'm in, regardless of how many dimensions the build is in.

-

I don't suppose it could be a political token, could it? 1912 was a hotly contested election year. Please, no discussions of politics of less than 100 years ago.

-

On 10/31/2020 at 12:02 PM, Steve Sells said:

wootz does not have layers, its a crucible steel

That's why you need the unicorn blood, naturally. Allows for pattern welding of wootz without resolving the carbides into nothingness. The fact that it's glittery and rainbow colored is simply an aesthetic bonus. You could use griffin spoor, but that leads to undesired traces of phosphorus, and a stinky blade.

For something a design that complex, I second casting. Although if cast separately and attached, I would have serious concerns about it cracking or becoming damaged upon striking.

-

22 hours ago, ThomasPowers said:

Why around the disk instead of welding the disk on top of the ring and filing to true it up?

Because that would be easy, and make a lot more sense? *slaps forehead*

Pnut, you reminded me of when we used to make barkeep's "friends", basically a Louisville slugger with the end cut off, drilled out, and weighted with lead. It was easier to store, conceal, and swing indoors, but ya, it was a total bushwacking weapon, and I think they're illegal in many states. They also tend to break in use if not wrapped in friction tape.

Cannot emphasize the no kiln dried wood enough. Part of the reason I'm not allowed to watch forged in fire at home anymore was shouting at the screen every time they take a 4 kazillion layer wootz blade quenched in unicorn blood and the urine of red-headed children (looking at you Theophilus) and attach it to a shaved down shovel handle.

-

At that kind of weight, aside from the high probability of injury, speed becomes a major issue, and you've got to be beating your hands to death when you hit something, especially if you've been using 3/4". Even with pipe, it's going to hurt. You're also going to be highly restricted on length, and part of the point of a pole arm or staff is that it's used to keep the other person at a distance, and often has to be kept moving. The shorter it is, the more you're moving it. Ever watch someone fighting with a bearded axe? It'll make ya dizzy.

For staffs, or any hand combat, I'll be the first to admit, I'm badly out of practice these days, but I used to prefer hard wood, old growth, and no kiln dried, for preference - with iron caps, but I've only used one with caps a couple of times. If you need a bit more weight, you could band it with iron, but if you go overly heavy, at some point you increase the chance of breaking it. Wood flexes, and absorbs more of the recoil. Imagine the difference between hitting a telephone pole with a wooden bat and with an aluminum bat.

Incidentally, when I've tried my hand at it, I found out that I suck at forge welding ferrules around a circular disc to make a hollow iron end cap. Anybody got suggestions?

-

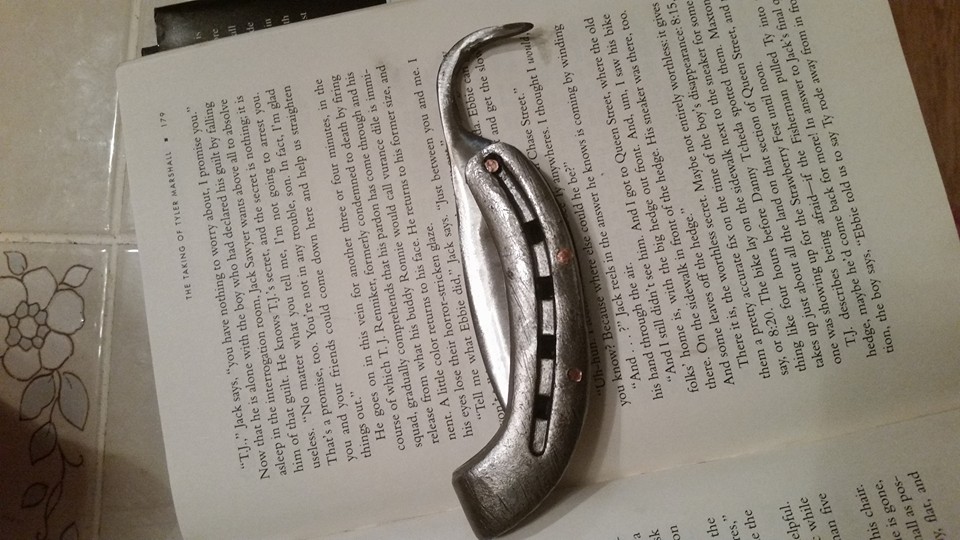

I had a friction folder I used to make by folding half a shoe. It's heavy and clunky as is, but you can file down the inside to about half thickness or so and it works well. Back end works as a hoofpick.

-

George, A locking, folding pocket knife, but the body of the knife is made from something like a .25" or .375" round rod, usually flattened on the side, and the attachment point for the blade is flattened into an offset medallion, like the half-penny on a scroll. There's a small place filed out in the top back of the blade, which holds the blade open with the body acting as a spring. Schrade used to make a very ugly one. There's an older Gary Huston video showing him making one somewhere; I can't find it. This is one of my early ones, if you couldn't tell by the terrible pairs of tongs.

Frosty, with pigs, I rarely got close enough to use vinegar until they were hammered. Those boogers are fast, and in the case of piglets when they stop in the grass, invisible.

-

Hitting a hay bale with a zwiehander is a bit like chasing a pig. Ineffective and it annoys the pig. Ask me how I know.

Incidentally, to catch a pig, train them ahead of time to follow treats, or get them blind drunk on cheap vodka mixed into mash. Of course then you have to move a drunk 300 lb. pig that can't stand up on its own from the middle of a muddy field. Whee.....

You brought back some bad memories, Thomas. I made a 5160 wire jack for daily carry on the farm, and tempered it a bit soft on the spine, on the theory that I would abuse the heck out of it. It took sharpening often with as much as it got used, but it survived the farm (now my ex's farm), the railroad, and the Army. Got used for everything. The first thing I used it for was well, to kill a pig. Also on chickens, as a screwdriver, auto repair, cut hoses or wire, making rabbet joints on hive parts, to spread cream cheese on bagels, opening feed sacks...you name it.

I made a small knife with a seax style blade, but I really didn't like it for farm work. I found I could slice stuff more readily with a bit of a belly on the blade. I had to finally sit the thing aside the other day so I could regrind the bevel (it wore high enough to be a bit wide) and put a new rivet in it.

-

E pur si muove. (And yet it moves) In this case, literally. When I use a harder anvil (which in turn has more rebound), I move more metal and I get less tired. Maybe your experience varies.

-

Fire works. But have you ever smelt it burning? Eww.....

-

Lot's of bleach will get the maggot smell out, for rot, it takes an mild acid, or for fat...man this got gross, for fat that's turned, it needs an alkaline. Don't ask me how I know.

-

The "dish" in the windowsill reminded me. You can use a broken piece of porcelain to sharpen knives, although you have to be careful not to scratch the blade. Done it a couple of times in a fix.

-

Still doesn't smell as bad as cutting bone with a power saw or a cutting disc.

-

There's several things to consider. You need to allow for zinc loss before adding it. Done right, you shouldn't lose more than about five percent. You don't want the copper heated beyond the boiling point, then add solid zinc at the last minute. You may also want to cool your alloy right after dissolving the zinc, and are you using flux? A heavy layer of flux on the surface will keep more zinc in the mix, especially since it's harder for it to burn without oxygen.

I don't know your experience level in casting, but you're taking precautions working with molten zinc, right? Zinc gasses do incredibly nasty things to the respiratory system, and I wouldn't give fume fever to my worst enemy.

It's just Aluminum brass, Frosty, they went to using it in coins after they had so many issues with Aluminum bronze tarnishing.

-

Kanka actually says on their website that undesignated parts of their anvils may be soft, with a hardness of 30-40 hrc. Love the look of the hollands and Jymm Hoffman's double horn colonial. I now know what I want for Christmas.

-

Good morning,

I've read that about oroshigane, in the far reaches of the internet, along with intense debate over whether it was tamahagane, or tamahagane including scrap, or any scrap billet made by the smith. Definitely internet fodder though, the Japanese swordmaking section of my library is a bit scarce, although I recently obtained Mark Kulansky's microhistory of paper, the Beekeper's Bible, and several books on the OMC stern drive they were putting in Bayliners in the early 80s. My love of obscure, or at least not mainstream texts runs in the wrong direction, I suppose.

I confess, I completely miss the 38 reference, unless it's the sum of the square of the first three primes, number of slots on a roulette table, or the caliber of a Saturday night special. Definitely Mister, btw. I would probably actually read that, although the only thing I remember about Taprobane is that it was Sri Lanka, I think? I went through a Greek history phase while I was in Iraq.

I remember reading about wind powered bloomeries, and copper furnaces elsewhere, and I would love to try the smelting furnace, but I only have scrap here, no ore and don't have the advantage of building on a hill (I'm on the water) to catch prevailing winds. I also have a small lagoon handy to the property that would be fun to play with, but I think the bloody homeowner's association would flip over a tidal mill. This the article? Juleff, G. An ancient wind-powered iron smelting technology in Sri Lanka. Nature 379, 60–63 (1996). https://doi.org/10.1038/379060a0.

-

For casting and for what smelting I've done, I've mostly preferred charcoal. If I remember correctly, (a definite maybe), orishigane was steel put together by Japanese smiths from selected pieces of tamahagane iron blooms (a famous steel made from Japanese iron sands in a complex three day process). Sometimes they added other bits of steel to lower the iron content. Tamahagane was the starting point for katanas, orishigane was the end steel for katanas, welded into a billet.

Mr. Powers has an intimate knowledge of metallurgy, and will assuredly know what I have messed up above. From my experience, he will also be able to recommend three amazing books, which will only have four copies each in existence, one of which will be his, and one copy of the rest you will be able to get from your local library through a lending exchange program.

I highly agree that you will want different setups for different ores. You will also almost certainly want different setups for casting than from smelting. Freshly smelted metals often take a good deal of cleanup or refining, and many behave differently from each other, depending on the other compounds they contain. (This is also true for casting from ingots made from scrap metal). Both casting and smelting can be incredibly dangerous and have steep learning curves.

If you have questions, I would recommend hunting down or joining a group or finding someone that does casting near you and taking a class, or seeking mentorship. It may help you avoid fume fever, or some of the funny looking scars that I got trying to teach myself. At least it's been enough years that you have to know where the white dots are on my legs, crucible failure suuuuuuuucks and should be planned for). Or there was the time that I spilled flux and accidentally created a small limelight. My wife thought that the sunburn was hilarious though. Mind you I'm not saying don't do casting, just that you will have a much safer, more successful time if you seek help.

-

Hard to go wrong with Coq au vin. The Coq is optional, the vin is not.

-

3 hours ago, Marc1 said:

NS ... do you still get africanised colonies in your corner of the woods?

Africanized bees, yellow jackets, murder hornets. We've got all of it...especially dang varroa mites.

Youse guys have inspired me. Gonna go work on the 74 Dart. Swapping a leaky fuel sending unit.

-

Me to Self: I'm finally immune to beestings again, I barely even feel them.

Bees to Self this morning when I was covering the hives which were being robbed: The moron thinks he's tough now. Good morning earlobes.

-

2 minutes ago, Frosty said:

"Apple proved a wrist TV wasn't going to sell."

Nah, but if you put it on a phone and stick it in your pocket...

Y'all aint' careful you'll be branching into fantasy. Can't read Adams and not Pratchett. And nobody mentioned the Outer Limits?

Is it possible to melt and cast railroad track steel?

in Smelting, Melting, Foundry, and Casting

Posted

Just once, I'd love to see a post that said, "Hey, just wondering guys, if anyone knew if it was possible to get with a reputable foundry and for $30,000 or so and cast a small run of double horn anvils using H-13 or some other air hardening steel. If I could participate in some small way outside of design, that would be fantastic!"

Instead, it's always, "Hi guys, I saw a YouTube video, and I was just wondering how to go about melting the souls of my enemies, unicorn tears, and some rebar by buddy Joe gave me into a useable three bladed sword made of Valerian steel using a Balrog and two salamanders. Could you please hurry? The Balrog is getting hungry, and ate one of the salamanders. If that doesn't work, I've got a popcorn tin casting furnace made of cement and as fuel, a mix of fulminated mercury and potassium cyanide. Has anybody else tried this?"

Response - "Hi, Welcome to IFI. Thank you for your interest and could you please post your location? What you're doing is illegal and moderately dangerous to the entire state of Nevada, and you may want to take this minor and cheap safety precaution, like approaching Balrogs only in the presence of Gandalf the Grey, or wearing safety goggles."

"Nah, I'm good, I've rethought the whole thing. I saw another video by the **** that said you can use plaster of paris and ANFO instead."