-

Posts

275 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Momatt

-

Jason do you just set that on top of the bottom die?

-

Thanks frosty, sounds like a really neat forge, too bad the coal situation is not great there. I’ve been thinking of cooking a drum of wood inside a 150 gallon oil tank and making batches of charcoal. I am unrestrained by neighbors for the first time in my life and have unlimited wood. I don’t want to forge with it but I have a extra large green egg kamado grill that eats a bag of lump every time I use it

-

Thanks !

-

Thanks George much appreciated!

-

Hello, I’ve decided to add a coal forge to my kit after using exclusively gas for a decade. I will be burning blacksmith or bituminous coal and will have a manual crank blower. I’m about to order from centaur forge and have four questions that I would really appreciate your input on. Now is my chance to get it just right and I’ll be living with it from then on. 1.) Fire pits are listed as coke or coal. If it’s a shape or volume optimized to burn one or the other I’d rather have coal. If one is just heavier than the other I’ll order the heavier one. 2.)do you prefer a round fire pot or a rectangle and why? 3.) Do you prefer a sliding gate vs a ash dump and why? 4.) The hearth or platform are 24 by 30 inches and can be had with the pot oriented in either dimension. Is there a type of work that favors one over the other, maybe it’s just which fits your space in the shop best and doesn’t matter. thank you!

-

Daswolf, thanks! I admire your work. I am very blessed to live where I do, wake up feeling lucky every day.

-

Thanks Billy and anvil!

-

-

I just got a 70 pound tire hammer it’s the clay Spencer type but with the newer modifications 8 inch anvil and heavier ram. I have no experience to compare it to but wow opens up new avenues compared to a hammer!

-

So David you are using a flatter to do it? I have trouble with the flatter handle jerking in my hand and bending.

-

How would you go about forging a wedge shape say like on a froe with flat dies? I’ve made a flatter and various fullers and am experimenting. Once I get something out of square I struggle with it jumping around. Still training my foot to let off the pedal it’s gotten interesting a time or two.

-

Next steps: I took a piece of a sway bar from and old car and forged it into the bit it’s spring steel I like a meaty bit then fire welded it in. I ground the top quick and poured hot vinegar over it to see the weld. I have a nice bit in there with the outer mild steel nice and even Tomorrow I will finish forging and hang it 1forguer he hasn’t gotten it yet, next weekend!

-

Jobtiel, once it’s wrapped I will forge the poll thinner, I like it 3/4 inch or so thick on the poll of the axe. This is just a preform I forged yesterday I need to cut a piece of spring steel off an old car sway bar for the bit which was under snow yesterday I couldn’t find it. As to the eye they come out an elongated d or a triangle but I will drift it with a teardrop drift.

-

Inelegantly worded I guess. I intended to reference that most of us use one of the wheels on our 2 by 72 grinders to fair the curves of things like axe langettes and encourage forging vs grinding just trying to generate some conversation on a forum that doesn’t see the traffic it did in the past. Also the attachment most used in my grinder and probably yours is the flat platen and that little 2 or 3 inch wheel on top gets a lot of use

-

Axe making is very rewarding and I think anyone can turn out one without a bunch of tools if you do a wrapped eye. All you need is a bar around a half inch thick at least an inch and a half wide 8 or 9 inches long. Using your anvil corners to start the eye and the poll you will easily see what to do next. This is the easiest forge weld, especially if you can tack weld the bit in place. I say it’s easy because it’s thick and once the bit and the rest of the axe are the same color white for a minuite it will stick! thought I’d share a few pictures of preforms to shoot for. If you want a Viking style with pointed langettes top and bottom they appear as you thin the area between the eye and poll. If you only want them on one side like in the photo below you have to continually push the top side down. Forge your languettes instead of grinding them it’s not hard. Every axe shouldn’t have the radius of a 2 by 72 grinding wheel but most do (including mine) Try a poll with fullers an inch and a quarter to and inch and a half apart and the eye one 3 inches or so apart. Try it and show us what you make!

-

Hello, I’ve been smithing for a few years now as a hobby. I’ve always used a chili gas forge. It’s been run hot now for a decade and stored outside. I’d like to switch to a coal forge as I live in the middle of nowhere now on 460 very rural acres. Smoke is no longer any concern and gas is a long way away. I’d like the ability to heat more specific areas, and not worry about fitting something into the forge. I successfully forge weld in my forge all the time but it never gets to sparkler heat and I’d like that extra heat level. Ive been watching for an antique to pop up but now leaning to buy one from centaur forge or build one, probably with a fire pot from dave Custer. How thick should the steel be surrounding the fire pot? Is a hand crank blower a pain? I’ve never used one. Should I buy a new blower or pick up an antique. Please share your thoughts and insights! matt

-

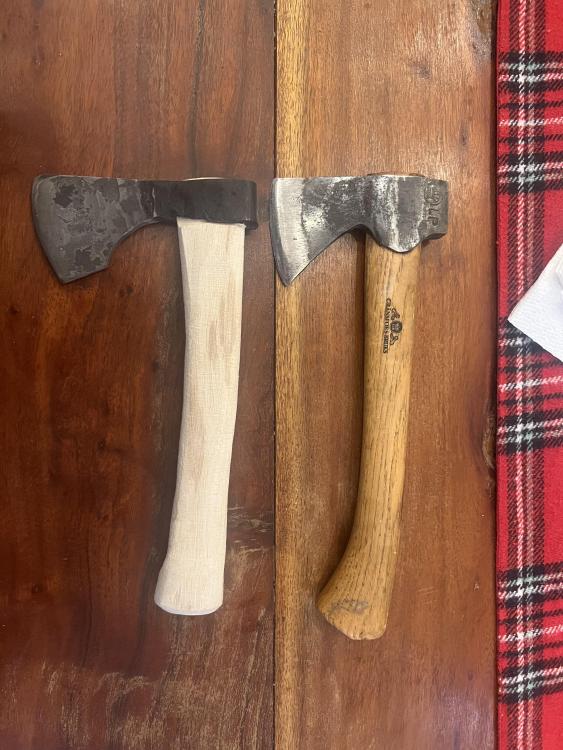

The handle is ugly but it’s white oak from my kindling pile! I can make a handle using my 2 by 72 grinder in a few min. And should have used cherry or walnut there is plenty in the pile and strength isn’t a factor. For some reason I always char my handles and rub in linseed oil. I like that look. My wife says I specialize in the over the top and unnecessary lol! I posted this to my Facebook page and I have a lot of friends wanting one.

-

George, great suggestion you are right!

-

Charles a few years back I had a gransfors mini hatchet. We did use it in the kitchen for a while just for fun.

-

My nephew is about to turn 8 I think I’ll put a little handle on this and give it to him. I made it same as a real one with fire welded bit. Eye got a little thin would have liked a pointed langette

-

IMG_3842.MOV

-

This fun pizza cutter axe I forged as a folded eye. made with step downs on the anvil corners. I just acquired a power hammer and my new technique is to fuller in step downs for the poll and eye with a piece of 1/4 inch round. These fullers are easy to feel on the anvil. Then I go back to the power hammer and iron the hill out with a flatter. Sure makes a wrapped eye axe fast and fun! Also I can make the half inch by 1-1/2 inch bar stock I like to use from scraps of whatever I have around, usually cultivator shanks. I go to my junk pile with the cordless portaband and then forge what I have into what I want. I’m in love with my power hammer

-

I made a good one from a mower blade. The most common one is made by necker. It’s curved sharp on the curved front it slices the back is almost square maybe a 10 degree angle. That’s your scraper for coon fat fox and cats. The slicer on the front is great for deer hides and coon shoulders.