-

Posts

2,024 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by Marc1

-

-

If you want it to look good, Pull it apart carefully and put it in molass bath. Like TID said, if the screw is good, and the spring works, probably needs nothing.

Are the jaws in good nick? Line up, no big cuts?

-

For the occasional user it's' OK at 99 for acetylene and 66 for oxygen. and you own the bottle for I think $200, no rent to pay.

For the heavy user you can't beat BOC for cost of gas and if you use a lot, retning is a non issue. The same goes for Argon for mig welding. I used to rent but now that I use less, bought my own bottle from Speedgas and refill when needed at a premium price but no rent anymore.

-

Poplar is soft, we used to make decent beehives boxes with it, Probably not very good for handles even when there are hundreds of varieties of poplars if you include the commercial clones and they vary in hardness.

if you want to experiment with different wood for handles, try Privet. Particularly the one with large shiny leaf, called Ligustrum lucidum makes great handles. Ligustrum sinense is better but hard to find a large enough branch.

-

Like others said, the more you clean it the more you expose the steel to the air. Leave the surface rust and oil it. if you really want you could rub it with wet and dry sandpaper and oil, but the important thing is the oil.

You could also rub it with plumbago. Fanciful but will make it look very nice.

Your anvil surely has a history. I like it. Is it a Peter Wright?

-

On 9/23/2016 at 0:01 PM, stan said:

I have a couple of oxy sets but the bottle rental costs are too high in Aust.

Not anymore. Bunnings size D swap and go.

-

I agree, yet the purpose of the seller is to achieve the best possible price at that point in time without affecting the demand. Too low or too high a price, the demand will be compromised. Reach the optimum price and the demand will be maximised at the highest possible price. That is a change in the offer or if you prefer, the supply.

However when the supplier is a person and that person is not just a merchant but an artist or an artisan, he will be handicapped by a long string of bias and preconceived notions of what is "right" and what is "wrong" and this will most likely influence his choice of price, and sabotage the outcome.

The buyer's bias that cheap is bad and expensive is good is part of the market idiosyncrasy and should be noted every time rather then interpreted as buyer's stupidity. It's a fact of life, the result of a culture, mass media advertising and a lot of other factors that work in the seller's favour. No one should feel he is cheating the buyer, rather understand that the buyer appreciates what he is receiving and pays what he believes to be good value. That is all it matters.

My comment about cost, again in the context of this forum that seems to be mainly about individual artisan workshops, is important because many time someone may feel bad about charging $20 or $200 for a lump of steel forged for a few minutes or perhaps an hour. The cost of the bit of steel, the coal used and the time is only one aspect of the true cost of the item. What is the cost of a painting worth $1000,000? $500,000? Hardly, only a few dollars of canvas and a bit of paint. The price is the result of the unique talent that is required to produce the painting or the forged item in question or a particularly clever software, and that can not be measured easily but the creator should always be willing to get paid what people are prepared to pay without feeling guilty about it.

-

Crane tracks make the best rail anvils if you can find them. Way bigger then train tracks ... I know a scrap yard that has a pile of them but it's in Sydney Australia ... a bit too far ...

-

After a long search and after buying 3 other anvils, two farrier ones at 40K each and one little Kohlswa at 25k, finally came across a decent size anvil in working conditions. There are a lot of extremely abused ancient clumps of metal sold as anvil around here, with price tags that would make your toes curl upwards. This one was advertised for 2.5 times the price I paid for it. And I still paid a good sum.

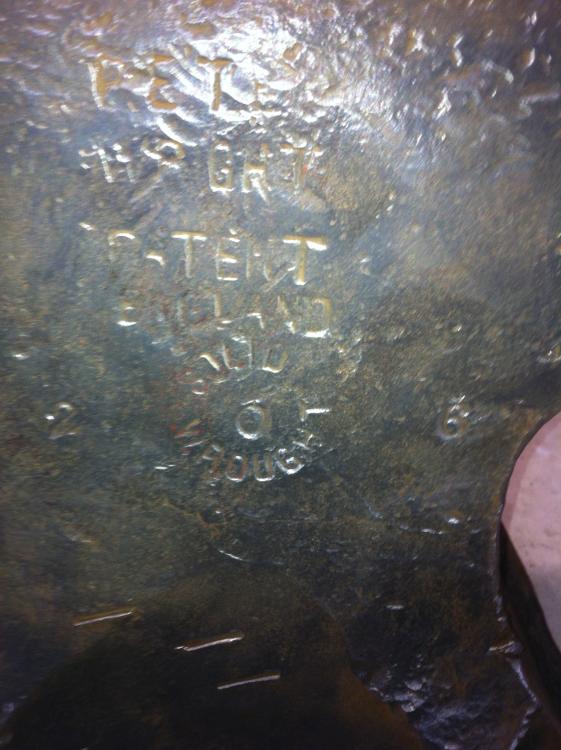

It's a Peter Wright marked 206 so 230 pounds. Surprisingly clean face particularly around the hardy hole, almost no use in that area. Plenty of marks of abuse on the sides ... chisel marks it seems, and someone's initials welded on the other side, fortunately had the decency to leave the manufacturer's marks alone. On one side there is a letter D and on one of the legs the letter W.

As you can hopefully see from the photos, one edge has a marked long chamfer that I can clean up and make it into a nice radius for forging. The opposite edge has two big chips, the biggest is about 6mm deep into the face and 10mm down the side but it has a radius so measuring from the edge at 45 degrees, it is about 3-4mm deep. The second chip is smaller.

i could of course make another radius and make the chips disappear but I am afraid that it is a bit too much metal to take off. I could also add a bit of weld to the small area of the bigger chip so that the radius will not need to be that deep. I am however reluctant to do so and compromise the heat treatment even when it is a very small area.

I could also ignore it and just round the edges off and use it when I need a bigger radius.

It rings like a bell particularly at the heel and has a very nice bounce.

Would also like to grind off those initials left on her by someone about 50 years ago according to the seller.

Sorry about the upside down photos.

-

1) NameMarc

2) LocationSydney Australia

3) What type blacksmithing do you do, what do you make.Haven't re-started yet, just getting ready.

4) How and when did you get started in blacksmithingMy father had an antique shop and he would commission local blacksmith to forge decorative pieces, beds, tables, lamps, chandeliers and sold them in his shop alongside the antique paraphernalia. He soon realised the market was good and started his own smithy. He was no smith, in fact he had 5 thumbs in each hand, but hired a couple of blacksmith and got me at age 15 to learn with them. I learned the trade and worked making all sort of items for some 10 years. Life got in the way after that.

5) What object or thing did you use as your first anvil,100k Kohlswa

6) Tell us about your first forge, hole in the ground, camp fire, brake drum, stacked bricks,

German made coal forge with pedal driven blower.

7) Who assisted you or encouraged you in the craftMy father.

8) What event changed your attitude about blacksmithing.

No change, always liked it.

9) What tool has changed or made your life easier in the shop.Never used a power hammer but sure would like to have a go. Mig welding beats transformer stick welding hands down, however I still have my trusty 3phase Lincoln bullet welder

10) What advice would you give those starting out in blacksmithing.Things are different from my days as a professional blacksmith and I have more years behind a computer than I had at the anvil, but as with any serious hobby or business, before you start, do some research, check out others, ask question and then find your own way. Only way to learn.

11) What advice would you give those already involved in blacksmithing.Well, I probably need to receive more advice then I can give, but for what it's worth, if you are a one man show, don't compete with price, rather be different and unique.

12) What are some of the interesting things that have happened to you in your life as a blacksmith.

At age 15, my blacksmith master made an ashtray for my mother's birthday (ashtrays was a common gift then). It was a grapevine leaf shaped to perfection.

I decided then to make something I would give to my future wife if I ever married.

I spent the next year forging a miniature chest a bit every day. I gave the chest to my wife 10 years later.

Please add any thing we may have missed or should have asked.What would you like to forge, something you have never attempted?

For me there are two things I like to try as soon as I get my new workshop going.

One is a rose forged out of one piece of steel.

Another is a set of chess figurines.

-

The first long post in relation to cost in the building industry or manufacturing environment has little relevance to a boutique operation like a blacksmiths shop is today. When the price in any transaction is ruled by offer and demand (among other things), the offer and demand in a large competitive market is more obvious and well known, then it can possibly be for one off hand made goods in a weekend market.

In Forsty's post, this becomes clear. The price was not set right, not at the intersection of offer and demand. The market at that point in time was prepared to pay a premium for this particular product. There is no point in judging the buyer because he is associating right or wrongly high price with high quality. Only accept it as fact and experience will tell the top possible price that can be asked for a hook in that environment.

A much more interesting topic would be to talk about how different people work out their cost, and decide if they have made a profit or a loss.

The perception of value is inextricable from it's price. Talk to a doctor that works in two surgeries, one where he does not charge and another where he charges $100 per consultation. The value his patients give to the medical advise dispensed will be completely different.

Peter Wright Anvil 1 2 12

in Anvils, Swage Blocks, and Mandrels

Posted

Wow, never seen an avil carved up like that. What would you use that for?