-

Posts

111 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by digger9523

-

-

Yeah i agree no heavy use.

Thought it might be good for cold forging copper sheet and other soft metals though?

-

Thanks folks!

I used some very dense antler on the handle, did all of the roughing out and then sanded by hand through several different grits. Finished on 400 grit and then ran the handle over a polishing mop.

The denser the antler the better in my experience. For you guys in the US of A, try and source some Caribou. Reindeer over this way have very dense antler, don't see why Caribou wouldn't be the same.

My antler is Barasingha, an Indian/Asian swamp deer. I used it because it's dense, but also because it's likely to have been a material that was once available to the original Ghurka knife smiths. It's CITES listed now, but we have them in deer parks here in the UK, so mine was sourced legally, as in not poached from the wild.

Polishes up a treat as you can see! -

Here's mine:

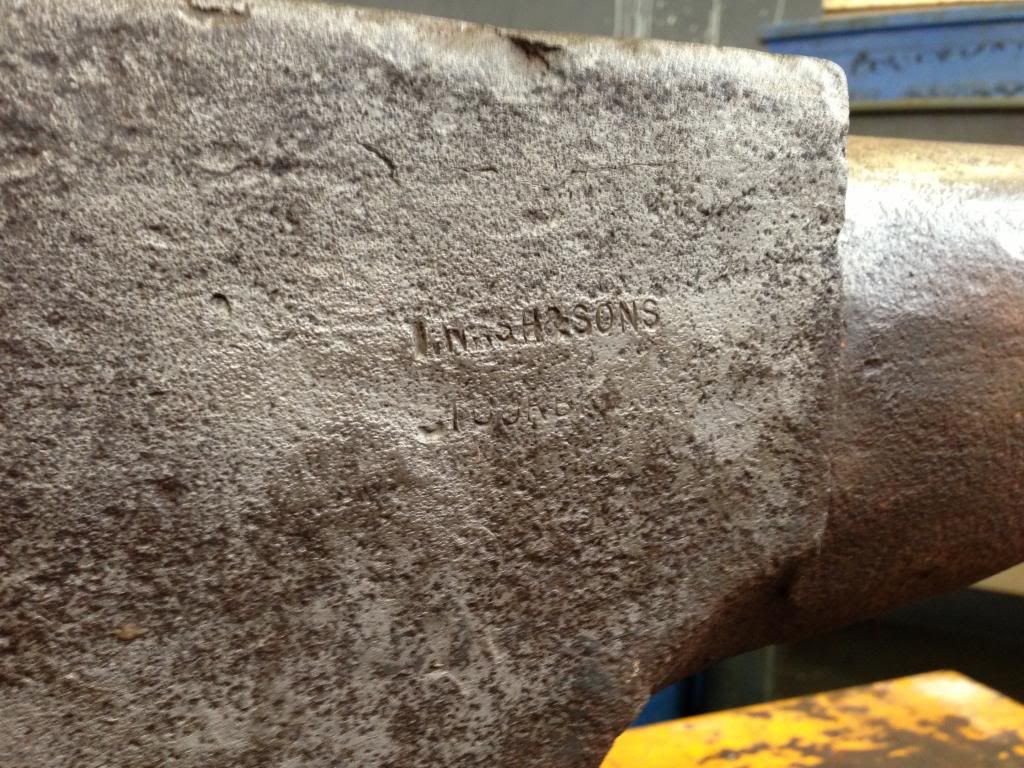

A 233lb Isaac Nash on a nice chunk of Oak.

-

George Lucas may be sending you a letter, be sure to have “plausible deniability”!

I've got broad shoulders, but they can slope Rapidly when required! :D

Glad you all like it folks and thanks for your comments. :)

-

Is that notch for The Rebels?

When you say "Rebels", do you mean Star Wars???

My 5 year old son said to me just 3 days ago, "Is that for the Star Wars good guys?" :-)

It wasn't done intentionally I can assure you, it was just meant to be a Fleur de lis! But it does bear a striking resemblance to the mark of the Rebel Alliance! :-) -

I've not seen one like this before, it's coming to me shortly:

These two pics are the Only other ones i could find on Google, one in Australia, the other in New Zealand:

The cute little vice on the back is a nice touch! My one was found in a SCRAP BIN!!!! What is wrong with some people? :blink: At least it was saved! :)

-

Well, after a good long while, i finally got around to putting a handle on this thing!

All over winter i used the blade for splitting kindling, so I'm happy it can take some use, but it Really needed a handle. I've been puzzling for months about how to do it, and i eventually decided i wanted to use antler.

Wanted to do the handle in as near as xxxx the shape of an original, but in use the back of the handle on an original can dig in, especially as the handles are usually so small, so i decided the handle would be bigger, and slightly modified!

And there it is, all over now bar the sheath!

-

Digger your math is OFF! 112 + 28 + 13 = 153# NOT 158# I see those numbers too. It won't be worth millions but I think you could easily get around $300 for it!

Tiredness kills they say! :lol:

-

On picture two i swear i can see 1 1 13 spaced across the side, so it's the weight numbers.

1 hundred weight (112 lbs) + 1 quarter hundred weight (28 lbs) + 13 Lbs = 153 lbs. If you weigh it and it's close to that figure then I'm right.

Hope that helps some. :)

-

I really like that. Great job

Thanks mate!

Here's where I'm at after an hour or so on it at work today:

-

Definitely.

Planning cow or buffalo horn like on the current issue originals. Need to source a nice piece if i do that. Or, i may do it in some nice wood more along the lines of the WW 1-2 period knives... Decisions decisions! -

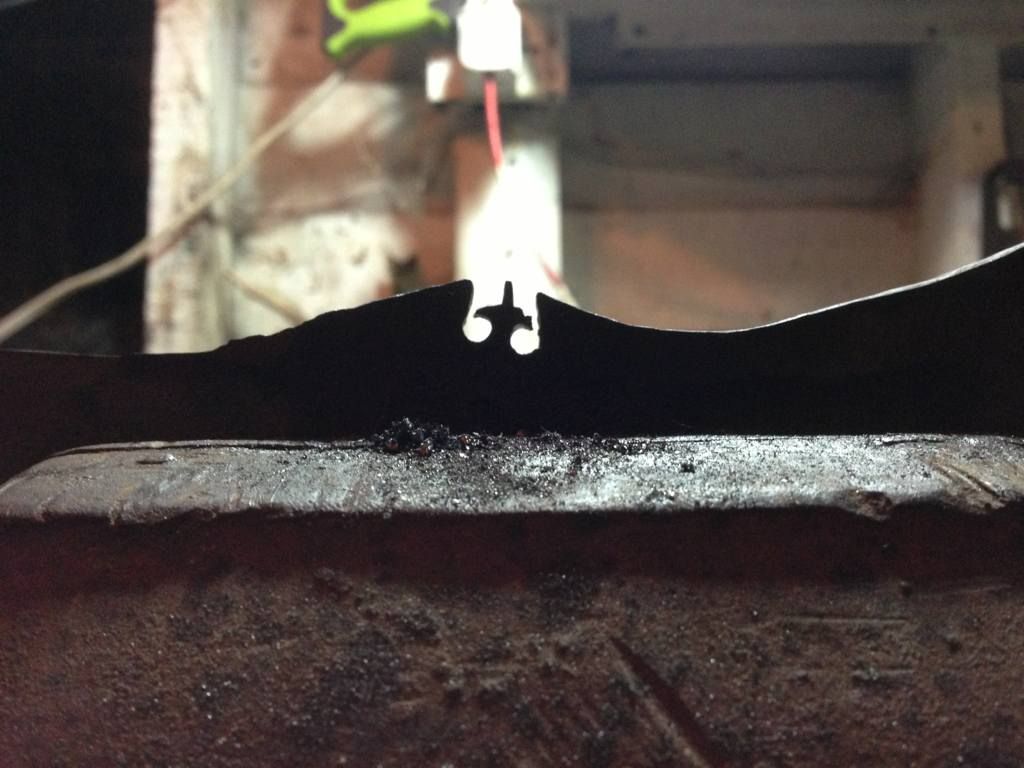

Had a few hours in the forge hammering out a Khukri from a piece of old Land Rover leaf spring. This is what i have so far:

Filed out the notch:

This was at close of play last night, think I'd earned a drink at that stage!

Today, after a heat treat, brief tidy up and a sharpen we're here:

Hung some rope from a beam and cut through it, then chopped through a 4x2 with no problems, so I'm pleased so far!

Giving it a better tidy up at work tomorrow.

Thanks for looking, please feel free to comment good or bad. :) -

Yes, that is pretty cool. Christmas not far awayMate, you'd better get busy 'cause when family and freinds see this, they're gonna want 'em in their stocking....

Funny you should say that mate, these two have already been dispatched to Terra Australis! Got family in rural QLD, they'll be crackin a few stubbies open out on the station with them soon i reckon :)

Next project is my first dragon head, then a bottle opener with a dragon head along the same lines as the leafy ones :wacko: -

Thanks folks,

Did this slightly different version on Saturday morning:

-

Nice mate, and I guess for a 'lefty' you'd just cant the leaf the other way. A well-earned beer......

That's the idea mate, or in the future have the leaf sitting straight as an ambidextrous option :-) -

Been thinking about this all day at work, had to give it a go as soon as i got home!

:) -

Beautiful anvil, but I gotta say that's probably the worst anvil stand design I've ever seen! ;)

That's my patented anvil painting stand! On the look out for a good stump as we speak. :) -

I'd check to see if it shows any signs of "working" in use.

Don't sledge or draw down stock bigger than 1" over the horn and you will probably be ok. If the horn falls off under light usage then weld it back on. If it doesn't fall off then you will have spent your time forging rather than grinding and welding, and that's the whole point of what we do, isn't it?

Good advice fellas, I'll keep a beady eye on it. -

Some of that crack around the horn might be from the original forge welding of the horn to the body and not mean much

Hope so Thomas, you can see why i was concerned though, doesn't look pretty. Time will tell on it. Do you think it would be worth running some weld over the crack? -

Why did you paint the face? Anvils never came that way and were never used that way. I guess if your into burning paint fumes its good.

No paint on the face, what you're seeing is purely what was left behind from the rust converter. Won't stay that way long ;) -

And finally...

Gave her a coat of rust converter and then some black Hammerite. Should get another 100 years at Least out of her now! -

Continued...

The crack:

-

Picture paints....

-

Well kids, I've brought her home and had a clean up. She's not a Peter Wright, she's an Isaac Nash! Done some military service, two other name stamps in the body with the broad arrow next to them, pics to follow.

There seems to be a bad crack around the thickest part of the round horn, enough of one to make me fear to bang on it. T'is a sad thing, but can't complain with a freebie!

Incidentally, she weighs 233lbs

Some file work i did last night....

in Knife Making

Posted

This is a stock removal blade, but i was quite pleased with how this bit of file work came out:

:)