-

Posts

243 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by bipolarandy

-

-

"HOW ABOUT WE ELECT PEOPLE WHO LOWER GAS TAXES???????????"

Hahaha, you know how good we got it here? In the rest of the world they pay 6 or 7 bucks a gallon. -

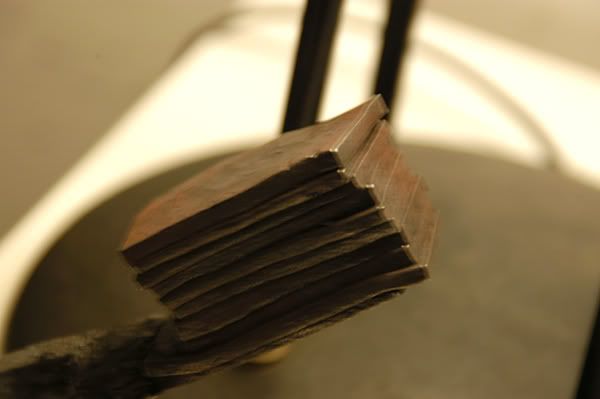

Valentin, I have seen a power hammer die kinda like that before, it was made for nail making, you would draw the nail out on the flat part, and then put it into a header and the end of the nail would stick down in the hole in the die wile you forged the head. Maybe it was used for something like that??

-

Nice knives sam, they remind me of that rivergazer kid knives.

-

Dang, I would say thats exactly how to build a hammer.

You've given me hope mark

-Andrei -

HEY RYAN, Get the xxxxx off my back!!!!,,, hahahahah,

Nice work, keep it up. Did you harden and temper any of thos blades, and what are you using to grind them?

-Andrei -

HI mt, and welcome to the fourm.

Your not that far away from me, I live in Buffalo Ny.

Are you a member of the New York state designer blacksmiths, we have five regions spread across NY. Check out their web site , New York State Designer Blacksmiths .

Are you just getting started in blacksmithing?

-Andrei -

woody, you have a fine way with words.

-

I use to fight with the same problem of my 20# tank freezing, then I got a different burner and forge( an atmo burner and not a blown forge) and I havn't had that happen since.

-Andrei -

i like the weight and feal of the 2# ball pane i have, I use that for most general forging. For larger stuff I use a 3# masons brick hammer.

-Andrei -

Im not sure what he is really selling, for $500? But the shipping is for only $22.00. I would think a few miles of rail road would cost a tad more than that to ship. Might wanna contact the seller to ask what your getting before you place a bid.

-Andrei -

That gave me about 640 layers( give or take ), I know iv lost alot of steel due to very oxidizing gas forge Iv been making this in.

Then I forged that billet out into a bar about 1/4" by 1" wide and about a foot long.

And scrolled it up into a jelly roll

I did the jelly roll because I thought it was a neato idea, and id never done one before.

Now im going to start forging that into a flat bar that will become the blade.

Its quite apparent how much metal iv lost during the forging. I started with billet almost twice the size of that.

-Andrei -

I thought id share some photos of the Damascus iv been working on for a few weeks.

Usually I forget to take photos of the stuff im working on as i make it, but I remembered to on this one.

I started out with one large diamond file, and a piece of 1045 that i drew out to the same dimensions. I cut those up, stacked them together and got a billet 8 layers thick.

Then I drew that out, and cut it into 8 pieces and re-stacked and welded it.

I did it this way to save my self the many folding and welding operations, And as long as you have use of a power hammer : ), i think its the way to go.

Now my billet has 64 layers, I forged it out again and cut it into 10 pieces and welded it back together.

-Andrei -

I got a 14" metal chop saw

, two sledge hammers (thanks richard!), and the book, "the craft of the Japanese sword" . Along with two other books about knives and the history of weapons.

, two sledge hammers (thanks richard!), and the book, "the craft of the Japanese sword" . Along with two other books about knives and the history of weapons.

It was a good day -Andrei

-Andrei -

Nice hammer, i like the style, But you need alot more practice on your welding. Thats a critical joint there and if you plan on using this to bash things, I'd go back and forge weld it.

Just my 2 cents.

-Andrei -

Make or buy a Gas forge that you can weld in.

Here are some pics of my homemade gasser i made for welding damask billets.

-Andrei -

Hot forging silver?!? He's a Witch!!!! Burn Him!!!!!!!!!

here is a iron penannular brooch i just finshed today,,,,,,

-Andrei -

talkin about knives from files.

Does any body know the actual alloy of any of these old files, like Black Diamonds or Nicholsons. I'v heard alot that they are close to 1095 and W1, but i'd like to know how much carbon is really in em.

-Andrei -

No matter who made it, the question is, how did it get out in the middle of the woods?

-

yeah, you know its bad when you set your leather apron on fire... i'v done that before

-

Oak, iv read alot about power sanders making the hamon line muddy. Is this true?

Do you use power sanders after the heat treat?

-Andrei -

elf, for you first forge, you should go with solid fuel, coal or wood charcoal.

Stay away from gas until youv'e learned how to forge, and be comfortable around a fire.

-andrei -

Hi Andy,

glad you made it.

I'll see you on wednesday with some drawing of the candle sticks.

-andrei -

sorry but your wrong beuler, i'v seen a smith up in Canada named Lloyd Johnson forge weld a barrel from flat stock. and to tell ya the truth, it didn't seen all that complex, or hard.

Its just forging a bar into a rough pipe shape and welding the seem as you go along.

As long as you have the time(it did take a wile) and the tools, swages and a mandrel...

im sure anyone that was good at forge welding could do it.

Now, the hard part comes later when you want to make that pipe into a barrel , then you have to bore and rifle it. and thread one end for a breach cap, and then shape the outside so its round or hex, or octagon, and polish it all smooth......

It was said that the old colonial blacksmiths could make a rifle barrle from start to finish in one week, and they had to forge their's from a 50lb block of iron, not flat stock....

-Andrei -

Here is the wash tub forge thomas was talkin about Charcoal Forge

It was designed for burning charcoal, and it works great for knives

-Andrei

no gas tuesday is tomorrow the 15th

in Problem Solving

Posted

AHHHHHH , PUNCTUATION ATTACK!!!!!!!!!!!!!!!!!!!!!!!!!!??????????????!?!??!?!!?!?!?

haha, I feal like i just walked into a Mel Gibson film. Carefull pete, you might have a stroke from all that patriotism.

Why do high gas prices = Socialism?