slimpickins

-

Posts

43 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by slimpickins

-

-

Vise Groove

in Vises

-

Going to fabricate a Guillotine tool. What’s the best clearance size between the dies and the holder/frame?

-

Thomas, Australia at one point manufactured locally many US brands such as Plumb, Stanley etc, using Aussie steel (alongside our own iconic brands) when shipping across the Pacific from the US was not economically feasible, as well as stocking some US made tools when US made, was known to mean made well. I’d say it was a lot more common to find some of yours over here, than the broad arrow and others over there. Most of what is left of our iconic brand names is the name only, as most, if not near all our steel manufacturing has been sent offshore, an idea that your country I understand could relate to.

-

Thankyou for your response Thomas.

-

-

Burnie, the place outside of (west of) Lithgow on the way to Mudgee is called (google) Goodearth Lithgow. You may also try Clarence Colliery, which is east of Lithgow. Perhaps give either a call.

-

Ausfire, I like that.

-

On 12/9/2018 at 6:16 AM, ausfire said:

Those old wrenches would make great twisting bars with a bit welded on. And that augur bit in the plastic is worth more than you paid for the whole lot.

Good idea on the twisting bars, thanks, was gonna keep em for art-y projects. Yes it’s starting to warm up, got some other things to catch up on though, when it’s too hot tb near the forge.

-

-

New stand. 1 inch plate on 1/4 inch wall, 2 in. x 3 in. legs, which sit 9 deg. off vertical (no sand). 5/8 in. bolts with hardwood wedges to hold down extra tight. No caulk between Anvil and plate, but magnet under heel with kids bouncy balls jammed in handling holes keeps it all quiet with no ring.

-

-

....not the top, which is near perfect, but the underside. I’m going to make a metal tripod stand, which I prefer over wood, for my latest Anvil, and I noticed the Anvil is rocking on flat surfaces. There is actually very, very, little contact between the underside of the Anvil and the top of the plate I’ve chosen to make the stand out of, due to various high spots. In fact it’s all over the place. Am I better off by removing high spots by grinding/milling, or pad welding in the corners to increase surface area contact. How much contact is enough? How long is a piece of string?

-

Ha ha, thanks Mod, I understand shmick. No haven’t filled yet Marc, only painted it today. Going to see if she rings at all before I add sand/oil. It’s heavy as xxxx.

-

-

Hello, of what benefit is the oil, that is usually added to sand, when placing inside stand legs?

-

-

-

-

Two weeks to go till Ironfest 2013. April 20 and 21, Lithgow NSW Australia. :D

-

Nice Job. How long is (or how long would you recommend) that taper?

-

UVEX have lightweight glasses reducing UV and IR.

Catalog at http://www.uvex-safety.com/en/products/safety-eyewear/product-highlights-eyewear/

-

Some people/cultures also say it lets the Luck run out of the shoe, and into your life.

-

-

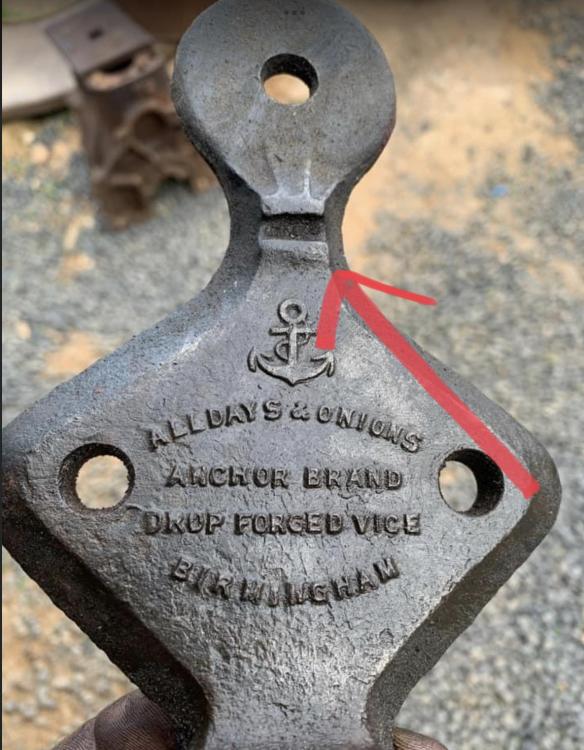

It followed me home

in Blacksmithing, General Discussion

Posted

Mid Century Draught table stand. 110lbs, 29” tall, 16” to 27” circumference. Free from garbage dump.