Brad L

-

Posts

82 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by Brad L

-

-

I started out making this knife for destruction testing but now it become my woods knife. The blade is 5160 triple edge quenched. Guard and pommel are wrought iron cord wrapped handle. The handle is soaked in fiberglass. 12" over all length, around 8" blade. What do you think?BradWithout getting into the story I just want to thank the people who got Iforge iron back up and running. I don't post a lot but I do spend time looking at all the cool projects on here and learning from all the other Blacksmiths.

-

and please stop calling them UGLY!!!

I can't stop now the BUK has caught on. Thanks for the comments guys

-

-

-

Here is a spike hawk I just finished. I'm not 100% sure the steel (Reclaimed Truck axle) however after a bit of testing I have a serviceable heat treatment worked out. 8" from edge to spike and 18" hickory handle (reclaimed pickax handle). I did a heavy etch to give it a old look. Comments positive and negative are welcome.

-

The funny thing was I thought it would be butt ugly but I like the look now that its done. Thanks for the comments

-

I have been playing around with cord wrapped handles a bit. Here is my latest effort. The blade is forged from 1084 with a wrought iron guard and pommel. The handle is full tang built up with leather, wrapped in cotton cord with cotton ribbon on the outside. The whole handle is soaked in epoxy so it wont undo. The tang extends through the pommel and is hot pinned. I think there is an slag inclusion in the blade so I'm going to pound the tar out of this one and see how it holds up. My redneck take on knifemaking :)

-

Thanks for the comments. I did not figure many would approve of my redneck take on Japanese knives.:)

-

What are those faint white lines on the blade in the first photo?The etch. I was playing around with etching the blade a number of times to try and create a patina that would hide marks from use. These lines came out and they grew on me so I left them.

I woulde like a closer look where the tsuba joins the blade :) I like what I see so farSure no problem, I hope this is what you meant.

-

Here is the latest one off my bench. My biggest to date 21" overall length. 5160 blade, mild steel guard, cotton cord wrapped handle soaked in epoxy. I was not sure about the handle it looks different but it sure feels good in the hand and it seams tough. This is not a presentation piece but a big ugly rough use knife. As always comments positive or negative are welcome.

Brad

Brad -

Wow blast from the past, I posted this knife a year ago. I can't remember how long the handle was I know it was a little short for me but it worked for the guy who has it now

-

What medium did you quench in?

Sorry for not answering the question sooner. I used 120 degree water, and yes it was nerve wracking. -

Thanks for the comments guys

-

The file was an original, not a Nicolson.

-

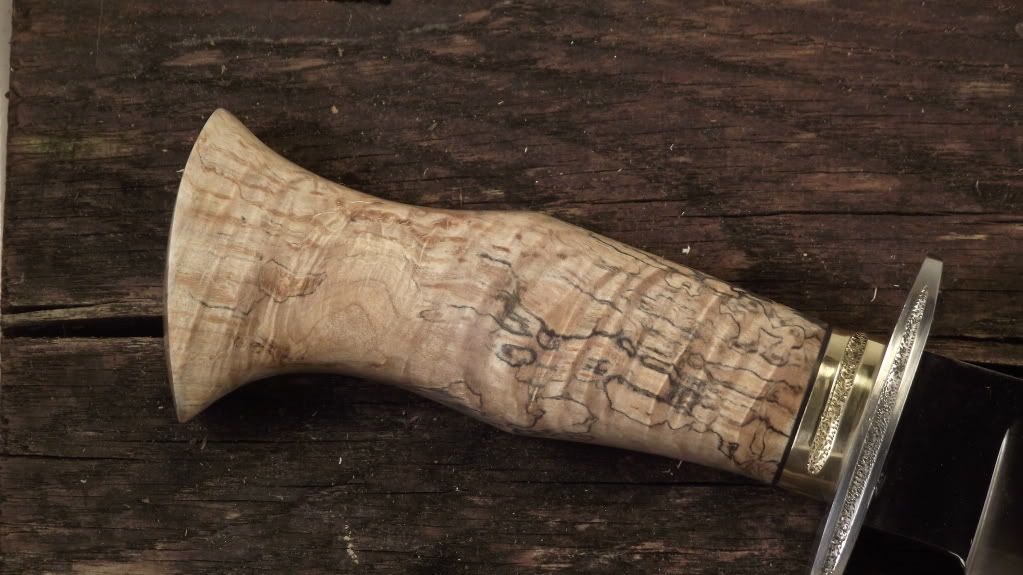

I made this one out of scrap I had in the shop. The blade is forged from a black diamond file, mild steel guard, brass spacer (salvage from a wear bar out of a fish plant I think) The handle wood is stabilized maple burl. I wish I could get some more of that handle wood.

-

I just finished this one up. 1084 steel edge quenched, brass guard and spacer, mild steel pommel and spacer (cold blued), with a little red spacer for color. What do you think? Brad

-

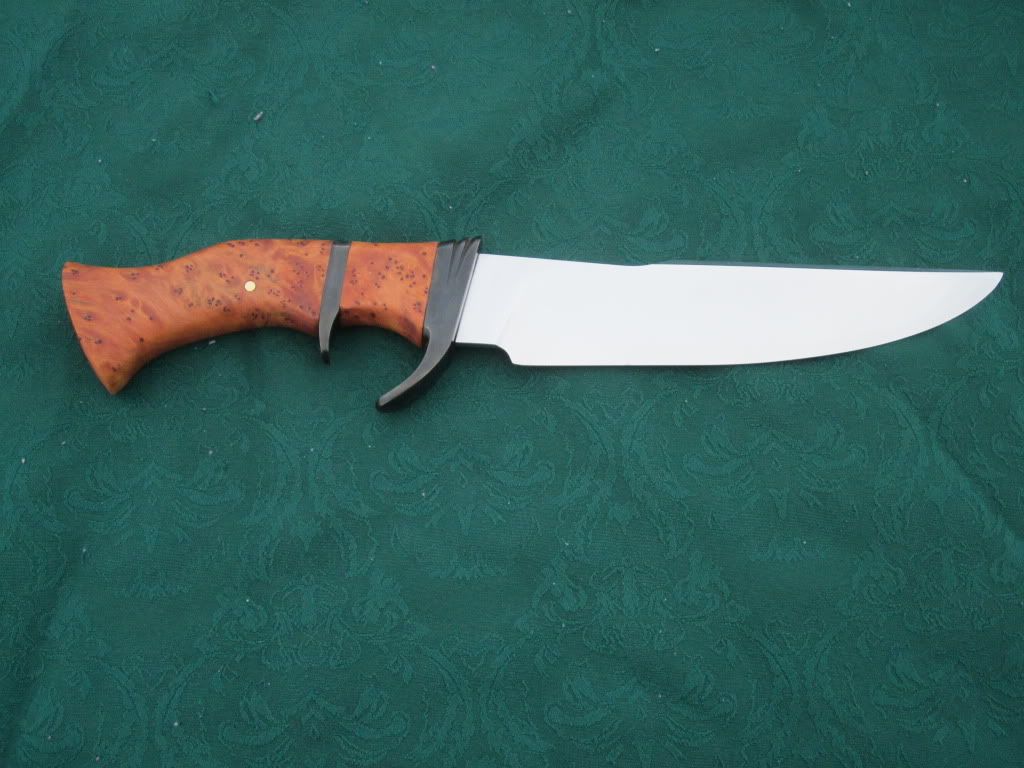

I finished this one up yesterday. This is way different from my style of knife but I think it turned out O.K.

I used 5160 for the blade the guard and subhilt are wrought iron, the handle is Amboyna Burl. I could not get the gaurd and subhilt to etch like I wanted so I cold blued it. What do you guys think?

Brad -

The outfitter my brother is using has dogs to corner the hog then it is all yours. They don't use dogs that can hold the pig.

-

Good ideas guys thanks. I think I will stick with 5160 for two reasons, 1 it has a good reputation for toughness 2 I know 5160 better than other steel types. I never thought about width as a factor, I will now.

Brad -

I'm looking for advice. I bought Ed Caffrey's video on knife making a while back and I was trying to heat treat 5160 his way (Edge quench 3 times and temper 3 times 2h at 350). So far this has been working out well for me, but now my crazy brother wants a knife to stab a pig. Apparently you can hog hunt with a big knife in some states. The outfitter recomends a sharpend clip. So I would like to build a knife out of 5160 with a hardend clip, but it needs to be very strong. Right now I was thinking of heating the whole blade to non magnetic 3 times and quenching in oil but tempering around 400 deg to give me a little more flex. I would think edge holding would not be as big a factor as durability.

Anyone have any thoughts? or advice?

Thanks

Brad -

Thanks for the comments guys.

The blade is 1/4" thick. The balance point is about 1" in front of the handle.

I have no idea about the type of cammo, it was a Frenchies purchase. (Used clothing store, very popular in the maritime's) -

Here is the hardest knife I have done yet. The blade is forged from 5160 triple edge quenched just under 10" long. I made the handle out of alternating layers of fabric, green, brown and digital cammo.

What do you think?

Brad -

I'm not an expert, but in my opinion the rough forged surface caused the blade to break. Good on you for putting your work to the test.

-

I made a few knives out of scrap, but now that I'm trying to sell a few I use known steel only. I used automotive spring(5160) and ball bearings(52100) for my stuff. I always tested my material by cutting a 1/2"x1/2"x2" rectangle off and harden it. I would heat it to non mangetic then quench in my slack tub (water). Sometimes the steel will decarb on the outside a little so I grind it down clean (Caution do not over heat it). Then I see if a file will slide over it. If the steel passes thist test I then clamp 1" it in my vice and hit the other inch with a hammer (use safty gear glasses, gloves, ect). The steel should break and not bend. If your saw blade will not pass these two tests I would not use it for a knife. I don't think people here are trying to hurt your efforts only save you from making a mild steel knife. I use a lot of stuff from Mr Wayne Goddard's book "50$ knife shop"

I hope this helps, good luck

Forge finished camp knife

in Knife Making

Posted

Don't worry she has had a rough life so far. I have been chopping slab wood (2x4 I can sell) Nothing like dry white spruce knots to test an edge. I'm just going to stop my testing before the vice and pipe :)

I did not know there was a percentage assigned to call something forge finished. The knife was fully forged but I ground the bevels and edge down. I guess I can always fall back and call it a "redneck letter opener"