-

Posts

2,478 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by njanvilman

-

-

Fisher Sawmaker's anvil. If used for general blacksmithing, be very careful with hammering as the faces are very hard. These were intended to be used to tune sawblades with the blade always between the anvil and hammer. The anvil was always protected by the blade.

-

If your serial # is correct, the anvil was made approx 1912.

-

-

A friend of mine was given a Fisher Saw anvil that was used for a lifetime by a saw tuner. He actually tested the face and it was around Rockwell 60. So if used for conventional smithing, be very careful. Missed blows can have consequences.

-

On 9/1/2018 at 11:59 AM, Frosty said:

Man, that thing would look GOOD painted my shop colors, gold star on hunter green. Beautiful, just lovely.

Not that it looks bad now but . . .

Not that it looks bad now but . . .

Frosty

But the anvil is about 6000 miles away from you. A long hike. Someday everything will be liquidated. I will let you know a month ahead of time so you can begin your journey.

Yup, the difference in 11 lb of iron is almost insignificant. Maybe 1/4" in height.

-

On 8/31/2018 at 8:31 PM, njanvilman said:

Soon to be added to the collection STAR #27. Second heaviest STAR anvil known. Top face dimension of 12" x 6 1/2".

The part of the post with the weight got edited out by an Admin. The anvil is 314 lb. There is a 325 lb (unverified) identical pattern STAR out there too.

-

-

51 minutes ago, JlBlohm said:

First time seeing the handle oriented that way. Mine is horizontal.

Most handles are horizontal. This anvil is only 3" wide so it would have fit horizontal.

-

Second smallest FISHER Sawmaker's Anvil listed in their catalog. This one has a 3" x 7" face, 5" tall. It is listed as 35 lb, but this one is stamped 37 lb, which is what it weighs. This one is dated 1931.

Fisher made Sawmaker anvils from 32 lb to over 600 lb. Most made were in the 100 to 300 lb range.

Fisher made Sawmaker anvils from 32 lb to over 600 lb. Most made were in the 100 to 300 lb range.

-

Good morning AA

I would only do a cleaning with a mild detergent and water rinse to get any dirt off. Then leave it. Nothing more is required. Leave the original patina. A light oil spray on the top would prevent further rusting.

This is a standard size Fisher sawmakers. They made about 50 different shapes and weights, from around 30 lb to 650 lb. Everyone seemed to want something exactly to specs, and Fisher was very accommodating. If they did not have a pattern for what the size the customer wanted, they would make one.

I would possibly be interested in this piece down the road. Please check out my "Fisher & Norris Factory Museum" on Facebook or just Google it for more info. I too am very passionate about Fisher anvils and now have the largest collection. Soon to have a book on the company done.

I have attached a photo of the bronze stamp that was used to put the logo into the mold on the anvil. This is probably one of the most unique pieces in the Museum.

If you are ever down in NJ, contact me for visit.

-

Good morning. Nice looking Fisher Saw anvil. Made in Trenton, NJ. There might be a date cast in. Also there might be a factory weight stamped in. The faces on these get very hard and brittle if they were used to tune blades.

Just clean it up and oil it.

Any other questions about Fisher or your anvil?

-

Your anvil was made sometime between 1941 and 1944, according to AIA.

-

You anvil was made around 1917, according to AIA.

-

10 hours ago, foundryguy said:

I have entertained the idea of making a 1,400 to 1,450 lb double horn anvil in H13. With gates and risers that would be my limit on weight. Would there be a market for this? It would be in the 6 to 7 K range

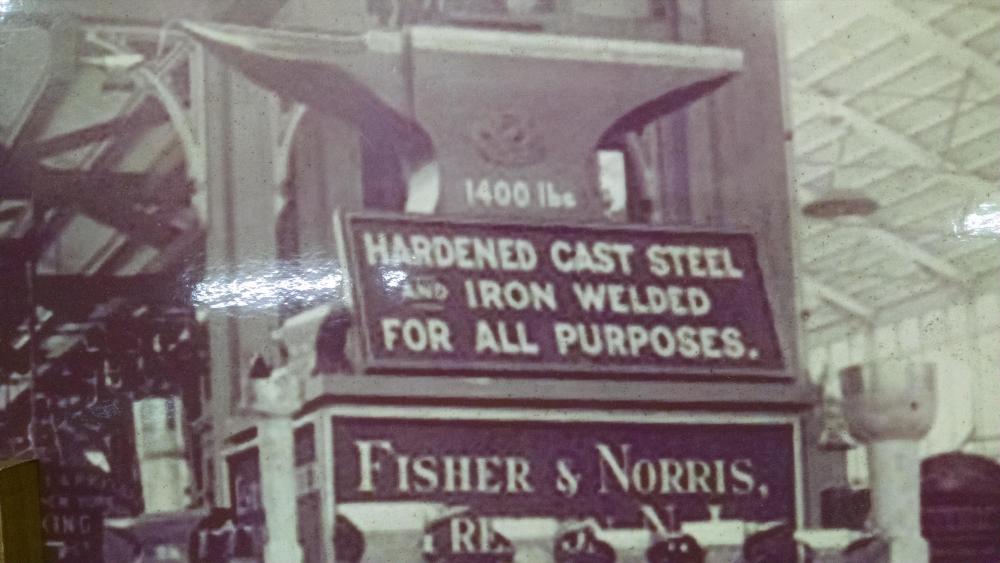

I have an exact size wood replica of the FISHER 1400 lb anvil in the Fisher & Norris Factory Museum. Perhaps it would make a great pattern if you ever want to create this size anvil. The original anvil still exists in the State Museum on NJ. The original was made for the 1876 Centennial in Philadelphia. PM me if you want to further discuss this.

-

I will try to answer some of this.....

The basic method of making Fisher anvils did not change much over their 120+ years of manufacturing. The only difference I would put out there is that the steel face material was probably better in 1919 than 1850. I have many anvils in the Fisher & Norris Museum, and most have held up well. Of course I do not buy any that are worn out, missing faceplates, broken and the like. Some anvils that are well over 150 years old look new, others are beat to death. Same goes for the newer one.

Given the similarity in size and vast difference in price, I would think the 1919 one would be a better buy.

kjbarth...do I know you? Perhaps you should visit the FN Museum and get an education on Fisher anvils. Just contact me via PM for a time.

-

What I know of: There is a 900 lb Trenton somewhere out there in the US. Fisher & Norris Factory Museum has a 800 lb London pattern and a 1000 lb #10 Chainmaker's anvil. The 1400 lb Fisher made for the 1876 Centennial is on current exhibit in Trenton, NJ at the NJ State Museum. There is the 1354 lb Wilkonson Jr forged anvil privately owned near Manchester, England. A friend in Brazil has several forged anvils over 900 lb; the largest almost 1200 lb.

-

The shape looks Hay Budden. The 0 inspectors mark is a HB characteristic.

-

3 hours ago, Cavpilot2k said:

I have to say, now that I've begun using it regularly and in earnest, I absolutely love my 173 lb Fisher. My forge setup is outside (I keep the anvil oiled and under a grill cover) and I am certain my neighbors appreciate its lack of that classic bell-like ringing. The thing is a workhorse!

Welcome to the club of Fisher anvil lovers. Use your anvil in good health.

-

-

On 7/8/2018 at 7:02 PM, MC Hammer said:

Beautiful. Do you use the wire cup on an angle grinder or electrolysis to clean them up?

All depends on how they arrive. The above one came as you see it. Nothing done. Painted ones get a soak in Simple Green to remove the paint, then whatever it takes to clean them up. Finally usually Gibbs Oil for preservation. Rusty ones get wire brushing, wheeling or whatever, then a good bath with a detergent, then oiling. A few get left with the paint or patina.

-

-

Moved some iron today to make a more cohesive display: I put all of the FISHER Double Horn styled anvils together. On the left top is a Custom Double Horn, 260 lb. Under it is a European Style 286 lb. Bottom shelf has another European Style at 380 lb. Fisher made at least three small versions of this style. On the right are four different sized Insonora anvils, made for the South American market. These seven anvils are among the rarest anvils Fisher made. On the extreme right are a few Hay Budden anvils.

-

15237 Serial number puts is around 1912. There are no accurate records between the years 1901 and 1912. AIA lists 15238 at 1912.

-

I am seeing 27112 perhaps as the serial number. If that is the actual serial number, it would put it from around 1917.

American Star

in Anvil Reviews by brand

Posted

Made in Trenton, NJ from about 1852 to 1868. They tend to be a bit brittle. You anvil looks to have lost it horn tip at some point, and it was reground to shape.