JDW84

Members-

Posts

12 -

Joined

-

Last visited

-

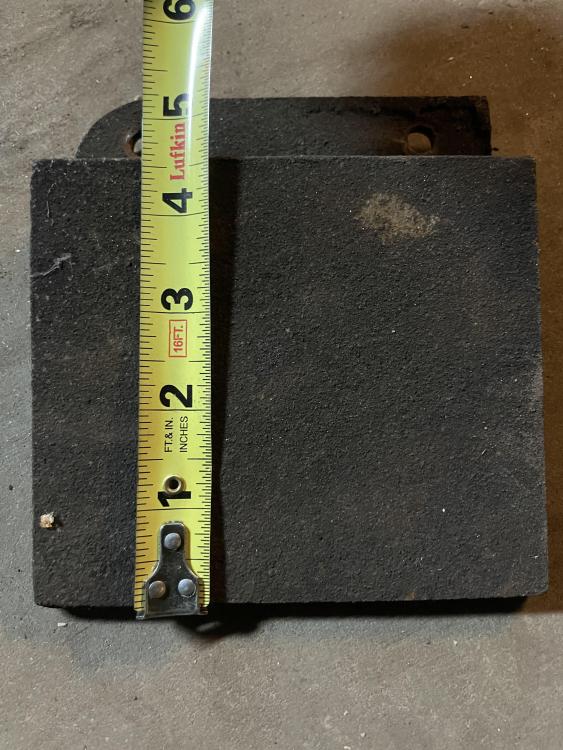

Well got almost everything together, the only thing holding me out that I don’t like is blower outlet flange is about a half inch offset to lining up. Also the blower to the gearbox needs some spacers between it to keep things from being in a bind. If I’m not mistaken when I took it apart about 2 years ago it had washers stacked in between the blower and the gearbox on the bolts. I’m thinking I’ll make a 3/8 spacer and another gasket to get the 1/2 at the flange going to the tuyere. This should move the flange at the blower over 1/2 into alignment. When I originally took it apart the flange that bolts to the fire pot was broken, and looking at this now it was probably in a pretty bad bind originally. I may use the 2 pieces of the gasket material or make a brass spacer to go in between the blower and gearbox.

-

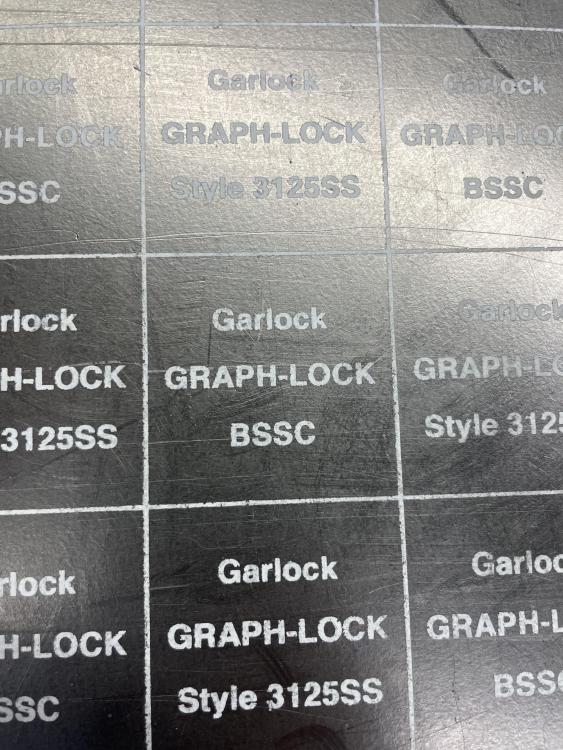

The stainless is so thin the razor cuts through it no problem. There’s some similar material that has a little thicker metal in it and it’s a little tougher to handle with the hand cutter.

-

Yeah these gaskets where they have the stainless in them, does better on something a little harder. The wood gives too much and the gasket kinda starts to delaminate. The lead is soft enough that it won’t damage the punch if you go easy

-

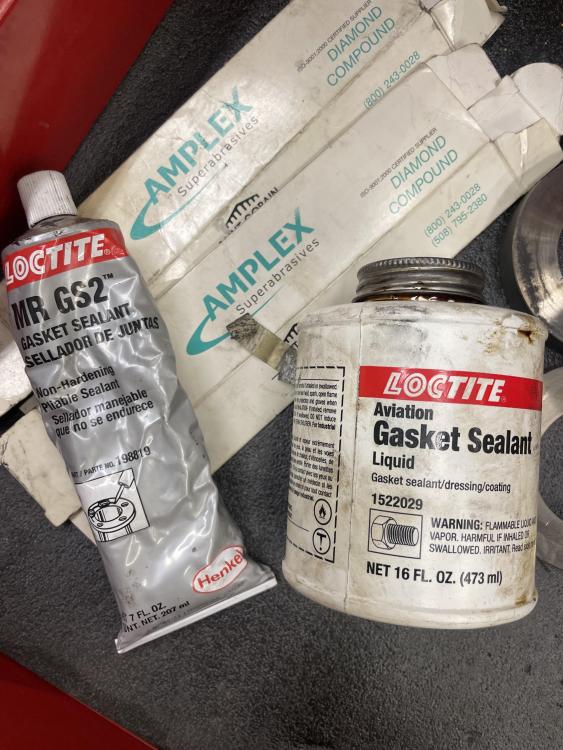

The faces of my flanges are pretty smooth, I’ll have to see how these gaskets do. Like you said put it all together and then start tightening things down. Humm, I wouldn’t be opposed to leading leaky joints. They do make a non lead alloy for people who like to use metal body filler like they used to do. A high temp Rtv, I do have some loctite sealants too. Just got some hot blueing a few of the bigger original nuts and bolts. I just looked, loctite makes a high temperature putty, but I’d say a good high temperature Rtv would work fine. I know the recirculation line will get hot but shouldn’t exceed what a good sealant can withstand.

-

No worries, I work on a plethora of things, some pretty old! What are you wanting to RTV?

-

I need some lead to punch the holes on. I’ll let you know how it turns out when I start putting it together. Don’t care a bit to make up a set for you.

-

I don’t know what those two extra holes would have been for. I’ve gotten the gasket material, it’s a layered graphite / stainless steel material good for high temperatures. We use it to replace old asbestos gaskets all the time.

-

Yep, they are there but as far as I know there wasn’t anything in them. There is a bolt that goes through where my finger is, well a counter sunk screw that comes through the back plate and had a nut on the inside under the air diverter plate. Those two holes at the bottom I’m pretty sure didn’t have anything in them.

-

-

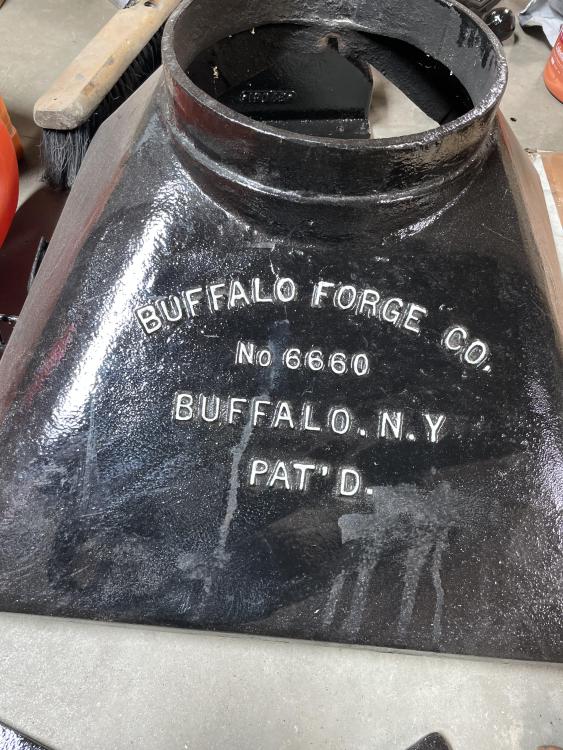

I wish I’d used flat black instead of the gloss but when I originally started working on this over a year ago I didn’t pay attention that it was gloss I had got. POR-15, a little pricey but good stuff. The gasket material will probably be grafoil material which is a graphite based material that we use quite a bit. I can buy the material or they will probably have scraps they will let me have. They have a machine that cuts them out, I’ll just have to bring them a pattern. Hope these pictures help!

-

I realize there may be some that frown on me painting it, but I like my things ti look somewhat nice. And I had to cover up the orange paint that was on part of it. The guy I got it from said he got it from a vocational school. I’ve had it awhile but it’s just been setting. I’ve got all new bolts to put it back and should start assembling it soon. Luckily I work in a large factory that has its own gasket shop and I can get new gaskets there. It’s the 6660 I’m out right now but as soon as I get back I’ll take a picture of the piece you are asking about. It’s basically a flat piece that stands out about an 1 from the hole. Could have someone break you one from a piece of 1/4 steel.

-

JDW84 joined the community

-

I’ve got this same forge, I’ve just taken it all apart and cleaned everything up. I know this is an older thread but I see people are still commenting lol!