-

Posts

21 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by HammerDance

-

Interesting! I should have known that. Certainly changes the perspective

-

Yes, it was 1986. Before I was born . Thanks for your help!

-

I found that as well, I just found it odd that the catalog lists them as steel body in every issue. I’m assuming sometime in the 50’s, then, they switched to cast aluminum. It may have only been a brief switch, I suppose. At least it’s not a... forgery

-

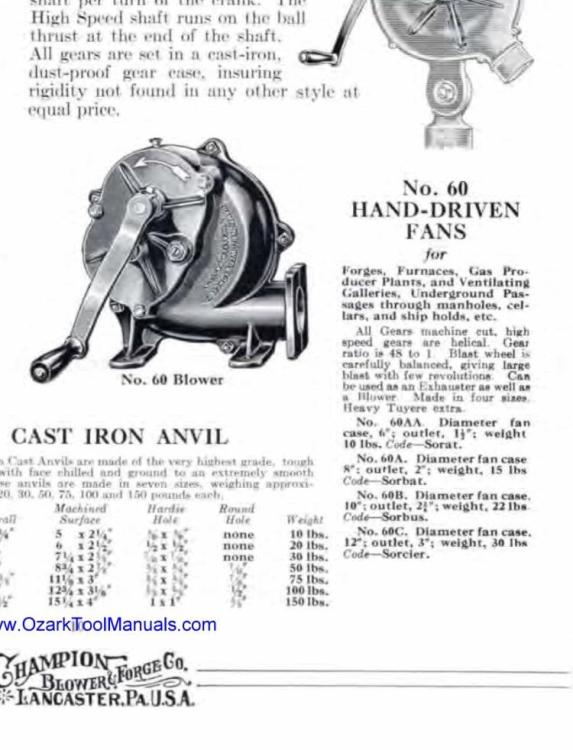

I recently picked up a champion model 60B hand-crank blower. More-so to satisfy my own curiosity, I’m trying to assign an approximate date/era to this thing. I see the 60 series in all of the champion catalogs that I was able to find online, but they’re listed as weighing 22lbs. This one is about half of the weight listed in the catalog. So, was there a period of time when these would have been either fully transitioned to aluminum, or maybe for a brief time period? I’m guessing it’s either a WW2 or early Cold War effort to re-allocate steel for military use. I’ve seen a few places online listing these as a “civil defense blower” for use in bomb shelters in the 50s, but even then the catalog seems to indicate that it should be a much heavier body. Or did I manage to find an elaborate Chinese knockoff of some sort? Either way, the price was right, and it works fine. Just curious.

-

I knew I read that in a thread somewhere. Perfect, I feel much better

-

I was a tin-knocker in a previous life, so this should be an easy one. Thanks again for all of your input

-

That sounds like the plan. I don’t want to mess with speeds, but instead just redirect the air as needed. we got a few inches of snow last night, summer is too far off to tease myself with

-

I guess I see an idle blower and an idle bellows as the same empty chamber when not in use. BUT leaving the electric blower on at a whisper makes sense anyway, so I suppose my concern was moot anyway. Thanks for the input, I was overthinking it. AC it is

-

That was my first thought, but then I came across a thread (somewhere in here, I believe) about gasses finding their way into idle bellows/blowers, and then igniting and creating a bit of a blowout. Didn’t want to aim that at my face, but a simple backflow/check would prevent that, I guess. Scared myself out of that option at first, but now air conditioning doesn’t sound half bad. Cool! As a chronic over-engineer-of-everything, JABOD is still my favorite concept. It keeps me from trying to reinvent the wheel (in most cases).

-

I’ve got cheap/free access to small electric blowers from time to time that I think would be (close to) ideal for use as a forge blower. However, these will all have a little bit too much oomph (scientific term), so I’ll have to dump some of the air with some sort of bypass so that the high static pressure doesn’t burn out my motor. Simple enough. My question is, is there something useful that I can do with that excess airflow, besides just dumping it back out into the open air? Would it serve any sort of purpose in inducing draft in the flue? Or should I just use it to keep the stink away from my boots? I’ll be able to ramp these down quite a bit, but there will still be extra air to get rid of.

-

Cool! Thank you

-

10 years after the OP, the link seems to have walked off. I’m interested to see it, if anyone happens to recall where the video came from.

-

I hadn’t dug too deep into propane burners, I think that’s still a bit too far beyond me. I also appear to have posted this in the wrong corner of the forum, originally, as it may have been better suited for the bellows/blowers section. I think I was looking at it as more of a science question, and thought it wouldn’t have a proper home in a more mechanical-leaning thread. Sorry, guys I think I was sort of looking at it from a side-blast perspective, I should have been more specific. But when you put it that way, it makes a lot of sense.

-

New Englander, doing historical research

HammerDance replied to HammerDance's topic in Introduce Yourself

I’d guess that I’m just shy of 2 hours south of Sugar Hill, so much closer to Brentwood. Once I get my feet underneath me a bit, but before I teach myself too many bad habits, I’ll definitely give them a shout. -

New Englander, doing historical research

HammerDance replied to HammerDance's topic in Introduce Yourself

As we speak. You’ll be the first to know, sir. Cheers -

That’s sort of what I thought. I was putting some pieces together that I had on-hand, but one had a smooth interior bore, and the other looked like it would cause a bit of “disturbance” in the airflow (turbulence may have been a poor choice of words). I knew I was overthinking it as I was overthinking it, but my curiosity got the best of me. Thank you! ps - in hindsight, a better visual example would have probably been the flue baffle in a water heater, rather than an oil burner retention head. It hit me as soon as I hit “post”.

-

I tend to be a bit nomadic, but currently I hang my hat in New Hampshire. I’ve sort of taken the reins in researching and recording my family’s history/genealogy, as other family members have gotten to old or haven’t had time to devote to it. As it turns out, I’ve hit a brick wall at a 19th century blacksmith on my patrilineal line. I guess it was in doing that deep-dive that piqued my interest in the trade, and I’d like to give it a go myself. I think in doing so may also give me a better understanding of the person I’m researching. My ancestor’s blacksmithing work took him from Maine to San Francisco (twice, I believe), and to Minneapolis, at the very least. The logistics of that in the mid 19th century seem pretty impressive, but I have very little idea what sort of projects he was actually involved in that would warrant that sort of coast-to-coast travel. He also found the time to join the Union army, and later the reserve (invalid) corps. The more I pour through these threads, and dive into old blacksmithing books, the more insight and understanding I gain. Now, I’m hooked. Thanks!

-

This may turn out to be a massive time-waster on minutiae, so be forewarned. Any idea if creating (or eliminating, if it turns out to be a negative) turbulence in your blowers’ air flow would have any noticeable effect on your burn, in a coal forge? Specifically, is there any sort of difference in oxygen diffusivity or saturation if the air is “forced” into your forge in a turbulated pattern, rather than just a straight shot? As an easy-to-digest example, the oil burner in your home furnace (if you use oil, of course) uses a flame retention head, which creates turbulence, and thereby creates the correct fuel/air mix for that application. Of course, there’s no fuel mix going on with a forge blower, but that’s the best example that I could come up with for an easy visual TL;DR - Maybe it’s just shower thoughts, but would creating turbulence in airflow give more control over the concentration of oxygen that’s fueling your burn?

-

I’ve certainly never been accused of UNDER-engineering anything, so I guess I wouldn’t be too upset with an over-engineered coffee table.

-

No pictures yet, but I’ll be sure to follow up. Thanks for the input, I appreciate it! I know for sure that I’ve thrown ‘portable’ out of the window with this one, so I’m just going to embrace it and see what happens.

-

I’ve got free access to a seemingly-limitless supply of (used) cast iron boiler blocks/sections from old boilers that have been replaced. Is a block section (I can grab one that’s 2” thick, or some big thick heavy monsters) something worth bringing home to build a stationary forge around? There’s at least 1 YouTube video where a guy built a forge from a boiler section, so I know that it will work well for at least the length of a YouTube video. But would it have any long-lasting pros/cons? I would assume that anything too thick would act like a heat sink and suck up too much of the heat that I’m trying to generate. But on the thinner side, is it worth pursuing? I don’t want to waste my time on something free if it’s going to be a drag. Additionally, I’d like to use solid fuels in this scenario. I’ve read through a few threads where guys were attempting to forge on cast iron pans, so I guess I just saw this as a heavier alternative that wouldn’t limit my future bacon intake.