-

Posts

20 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by VandegriftIronworks

-

-

Okay, I’ve breathed into a lot of coal gas it seems.

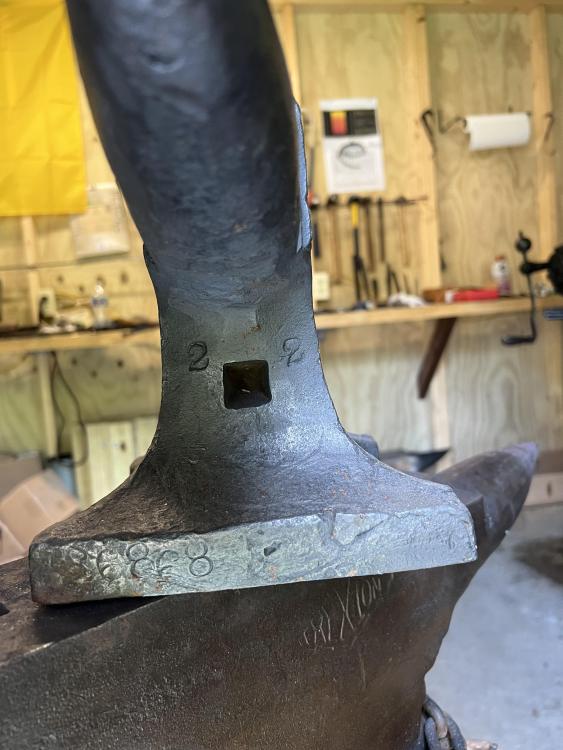

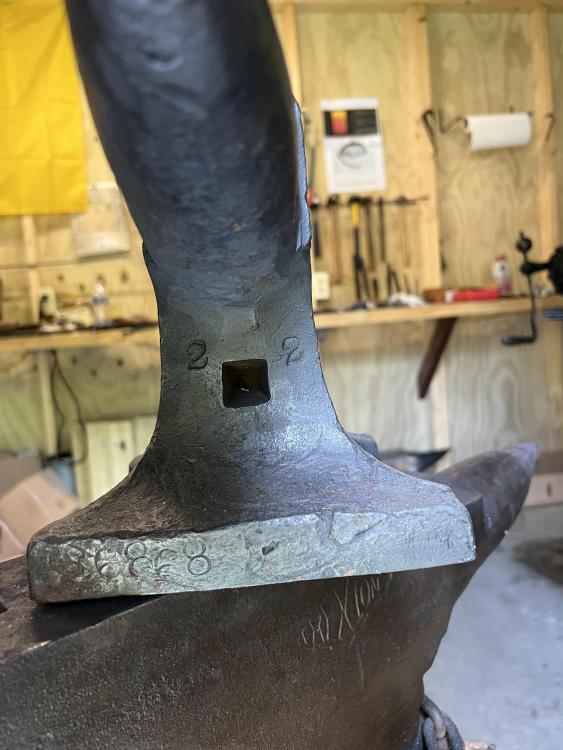

This is what I guess to be a 1922 Hay Budden that weighs 51 pounds. Have no clue why the brain said 1924 and 66lb. I’ll add some photos belowThe serial number is hard to make out, but from my best guess it says 86868 which would date it 1903. Far too confusing for my brain. Didn’t have a coffee today

-

Hey NJ,

yes there is, when I get off work in about 3-4 hours I can share it here. My goofy self forgot to take more pictures

-

Also I’ve been looking to downsize to buy my dream anvil, a 250lb Fontanini. They are just beautiful and I feel Steve won’t be making them for much longer.

Twisted, yeah I’ll have to let you know. That’s why I kept it for so long, figured it’d be a good starting anvil for kids too. However I need to make room for a big guy in the shop, and if selling some of my anvils off can fund the fontanini the kids may have to figure it out themselves :-)

-

I picked up this little hay Budden quite a while ago and have absolutely no use for it in my shop, already having a couple 125lbers. It’s in pretty good shape with some minor edge chipping and a small chip out of the horn.

many idea on the value of this little guy? I can’t find ANYTHING similar in weight for sale.I can take more pictures when I get to my shop this evening.

Thanks guys!

-

Picked up this 125# Trenton from a guy who bought it to put on his shelf, and discovered the shelf wouldn’t hold it. Paid $3.25 a pound.

She looks barely used, has 85% rebound, and will blow out your eardrums without a chain around it.

Serial is 125 (weight) 218793any clue as to year? it also has the TREXION typo

-

3 minutes ago, Irondragon ForgeClay Works said:

The fire pot does not need clay but the pan does, to prevent it from cracking, an ounce of prevention is worth a pound of cure.

Thanks, will my refractory cement suffice? Or should I run down to the local pottery supply and get some actual clay.

-

-

Here are some photos of the only (markings) I see on it.

Pretty much the same as my old hay budden. The only markings on that anvil are 167 and they are on the opposite side of the anvil from the branding, near the face. Nothing on the base or around it.

Also the screwbox is in fabulous shape, moves fast and smooth. although the leg appears to have been repaired. No biggie truthfully.

-

Hi everyone, picked up this new to me leg vice at yoders when I got my forge. Building a stand for it in the shop today. I believe it is a Colombian but if you know any different please let me know, also threw in a picture of my old Charles Parker (anvil Vice) No. 134 from 1925. I picked up that Vice at a yard sale for $75 last year!

-

Hi all, just filled up my blower with oil, says on the side (keep filled to oil plug) so I did that, now it is leaking oil into the hose running into the tuyere. It runs quiet and blows A LOT of air. So I don’t think there is anything wrong with it.

Is this indicative of a problem?

More pictures

Wowza. Just found the other plug... it’s hidden on the bottom, about an inch up the housing, maybe added too much ATF

-

Thanks anvil! I’ve heard a can of beans on the forge can make ends meet, if you only have a bean a day.

-

The trivet (top ring) is a forge welded piece. But I had actually never considered forge welding the legs to the ring. Might have to try that, I’ve been mostly copying examples I’ve seen in our books in the library on site.

Pretty much everything in the shop is based around the 40 years of research my boss has made, he’s a master smith and extremely informed historian. This shop is set mostly to resemble a 1774 shop, but some more modern (early 1800s) tools are seen to also represent the historical farm house on site.

Oops. Also I do have quite a bit of wrought iron in the shop, but haven’t clinked around with it yet. Definitely want to soon though!

-

Here’s some photos of my shop at work. I don’t own this shop or much in it, but it’s were Ive learned the trade.

Ive also attached some photos of some past projects. Don’t have a lot of pictures currently! Also I’ll post some pics of my shops set up as soon as I have it, well, set up (Reorganizing to fit the new coal forge)

Glad to be on board

-Ian

-

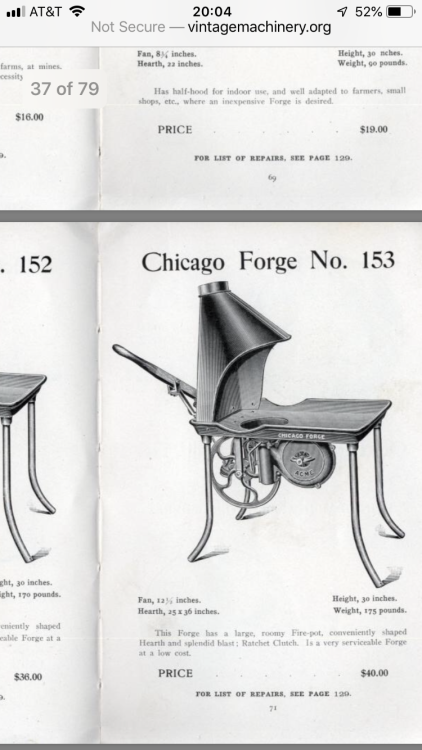

I really cannot determine a year on this model. But I believe it to be dated 1906-1912

Ive seen some people selling this catalog and estimating it was released in that time frame.

Wonder why they didn’t put dates on there anywhere.

Anyhow! This forge was a real steal for $700 with the blower included!

Thanks guys

-Ian

-

Hi everyone,

My name is Ian, I am from north-central WV. I began blacksmithing a little over two years ago as my first full time job. I was a essentially self taught apprentice, but also got a lot of advice from a very experienced smith who has done this as a life long profession.

This job was at a historic sight, and not only did I blacksmith, I interpreted the history of our historically accurate blacksmith shop set in the late 1700s.

I still work there, but also have my own slightly more modern shop, have set up an online store, and got my business license yesterday.

I’m currently 20 years old, but hope to continue in this trade as a large portion of my income. (Good luck with that)

-

Thanks guys for all the tips and help, I started updating my profile a bit.

See you all around, I’ll probably be here a while!

-

I found this in their catalog 8.

no year on the catalog of course, but it said you could order it with either a pump or cranked blower. So this may be the original set up almost entirely.

And the forge is currently clayed, I had just never heard of it before. Even at work during my apprenticeship our forges were unlined.

if I find a year I’ll let you all know!

Oh I see you mean claying the entire pan. I live in WV so I’ll get some clay from the creek right beside my shop

-

Thanks Willow!

Looking at the catalog they have this exact forge set up (Otto) as the Chicago forge.

Any idea of year?

-

Hi all,

first post here.

just bought a forge in Amish country, came with a functioning blower. Neither the forge or blower have any ID, the blower just has oiling instructions and the number 1075 and 1088 on it, plus a serial number.

Forge has nothing at all on it

if you can lend a curious smith a hand! It would be appreciated! Thanks

-VI

66lb Hay Budden from 1924, any idea on value?

in Anvils, Swage Blocks, and Mandrels

Posted

Don’t have a ball bearing to check rebound but she’s definitely alive. Rings like a bell. Here’s a video