TravisM

-

Posts

30 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by TravisM

-

-

Thanks mate I was happy how it turned out. It's fairly big 240mm x 57mm high

-

-

-

Ripped into this wagon tyre today.

I forged it from 20mm thick to 9mm. Cut it and cleaned up, the only high carbon steel I had around that thickness was an old worn out file so I used that as the core steel. I've used old files for kitchen knives before and I really like them as monosteel blades. It turned out to be a bad combo with the wrought, I've got way too much core left, hardly any wrought. I forged it almost all the way to shape just to keep the cladding where I need it but I'm guessing I'll grind through the a lot if the wrought layer. I'd be interested to know how other knife makers work with wrought.

L

-

-

So I've been chasing some wrought iron for san mai knives for a while, it's a bit hard to find here in Australia. I was looking to buy from overseas UK/US postage is pretty expensive. I got quoted £40 for 1 x wrought chain link £60 postage. So I started looking for wagon wheels here. I don't have a great knowledge of our steel making history in Australia. I don't know if we produced much wrought or imported it, any help would be appreciated.

The asking price is $200aud 1.5m wheel

-

Awesome mate thanks for the info

-

Roughly how many rods did you go through?

-

That looks great! Good job. What thickness did you have to build up?

-

Thankyou very much for sharing your experiences, I guess I'll see if I can get the right rods and make a decision if it's worth fixing or not .

-

Thanks for your reply. Have you tried doing this before? How did you go about the anvil pre heat and post heat?

-

Good on you for fixing it. You made it whole again

-

Thanks for the detailed reply, your numbers are very exciting, I'd love to give your knives a go at my work. I've had a very chippy knife in aogami super, I bought it when I was an apprentice 64 rockwell I think. Some of the knives I've made lately been a bit too hard to sell to other chefs so I keep the rock hard ones my myself.

I can see wootz in my near future, how viable is waste veg oil for firing a crucible melt thingo?

-

Beautiful looking knife. The profile looks great too. That's my go to handle shape in my chef knives.

After forging what is your heat treating process? How do you find the performance of your steel? Edge retention and all that?

-

That looks great, what are you going to make from that bar?

-

Ah ok I understand. Hows it holding up?

-

Well said, I think I'd have to agree with you. I guess there was just a part of me that wanted to make the anvil whole again. Thanks for your help

-

The anvil was $600 Aud, which is pretty good over here, and they are not really that common in the 100kg+ range around my area.

The anvil pre heating and post heating to build up the face, is that really getting in the range to ruin a temper on the rest of the face ?

I don't think I'll attempt it but how long would it take to build up that section with welding rods?

-

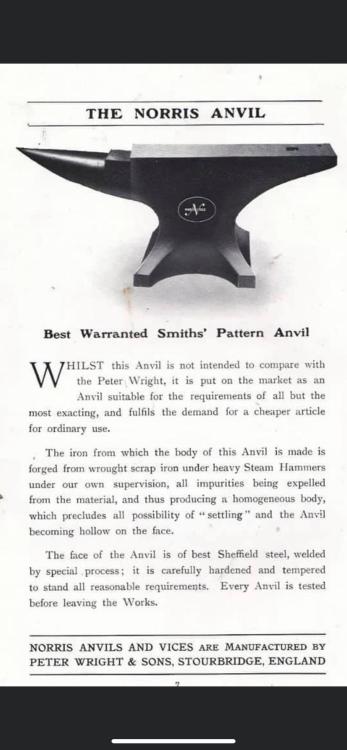

Hi everyone, today I picked up a peter wright 2 0 0 weight with a clearly busted top. The price was ok and the rest of the anvil still had pretty good ring and rebound. I'm wanting to fix the broken part but not sure how to go about it. Any heavy hardy use can be on my other anvil which is a bit bigger and not broken. I can weld fairly well and I have a supply of some 9260 at 8mm thick. My first thought was to harden a suitable size plate then weld it to the broken heel and grind it all back. Any thoughts would be appreciated. Thanks

-

Great job on the anvil repair, it looks fantastic. I'm wondering how many pieces of forklift tine you used and in what orientation? Just trying to wrap my head around how you done it.

-

-

-

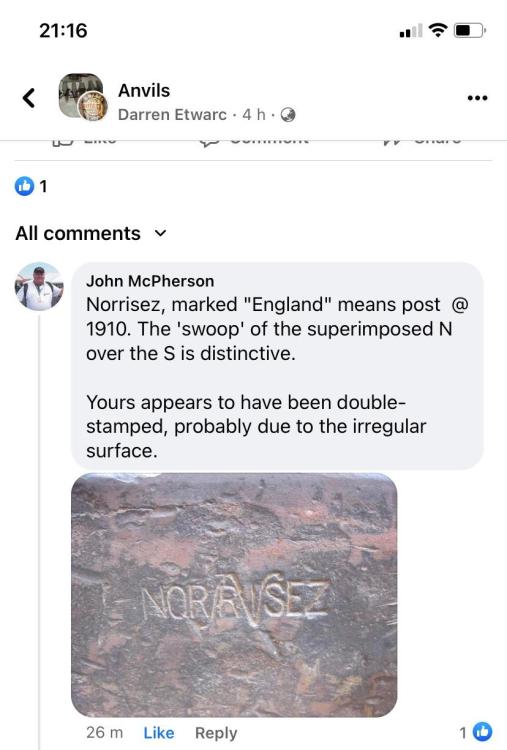

Thanks for all your replies, my new anvil has been put to use already. I love the history of a tool this old. Its a privilege to have it in my workshop knowing many before me have used it. Its a testiment to the workmanship and quality that the anvil that its lasted as long as it has.

-

Thats good advice, seeing as though I have a 6 week old baby and a 20 month toddler.

I'm wrapped I've got myself a decent anvil, it'll be well used and something I can pass on to my kids .

Wagon wheel Australia

in Metallurgy

Posted

Thanks Jono, I'll keep an eye out for railway spikes. I'll be up around Brisbane soon I might try to find some wrought souvenirs.

Cheers Travis