dian

-

Posts

41 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by dian

-

-

mikey, i have recently scaned though a book my michael porter. would that be you, by any chance?

On 2/14/2021 at 11:16 PM, twigg said:Lol Thomas

Dian, if you're thinking of the equations for compressible flow, remember there's friction and probably turbulence in the nozzles / mig tips (especially the mig tips!). If no energy is lost to heat or eddies, then 2:1 pressure ratio would get you to Mach 1. I suspect the flows are highly compressible, but I wouldn't want to bet either way whether or not they get sonic (especially in the mig tips!). Maybe you can make a burner with a de Laval nozzle for an accelerator, huh? (That doesn't sound very useful, I'm just pulling your leg)

(That doesn't sound very useful, I'm just pulling your leg)

yes, laval nozzle (orifice) in a lavale nozzle (burner) would be the ticket. there is a flaw, however, the flow returns to sub sonic on the exit.

-

maybe i missunderstand, but it appears that at a pressure ratio of a little over 2 the flow is sonic through an orifice.

-

interesting, because my understanding was that sonic speed at a pressure ratio of around 2 (?) was max atainable speed and the mass flow would be proportional to the pressure ratio above that.

-

the idea might not have been completely clear from the picture. the outer bottle neck is opened up to the id of the pipe and is attached too the pipe by the short connector. (actually there is 6° taper and a corresponding chamfer in the pipe with the edges blended in.) the inner bottle neck is closed by the choke. the air enters the pipe between the two parts through the annual opening that is properly adjusted for free air operation.

as soon as the choke is opened ever so slightly, the flame goes out, so im led to believe there will be enough reserve in the forge.

this tip indeed has a short orifice. however i can screw mig tips in there as well and frankly speeking i dont notice any difference with this or other burners due to the longer orifice. if i think about it, a long orifice will flow less and if more gas velocity should be needed i can go up to 60 psi. im sure you explained your idea with the "accelarator" somewhere. where do i look, please?

-

hi mikey, thanks for the feedback

trying to understand what you are saying: what "hole" should be 1-1.25" long? the orifice?

-

im building a forge that should be able to get to as high a temperature as possible. so i started experimenting with propane burners. i have built quite a few burners over time for hardening or forging small pieces and most of them are adjustable to the point where the flame goes out on the lean side. i quickly found out than more air is needed in a closed chamber than in free air so the goal is to have an even larger reserve to lean the burner out.

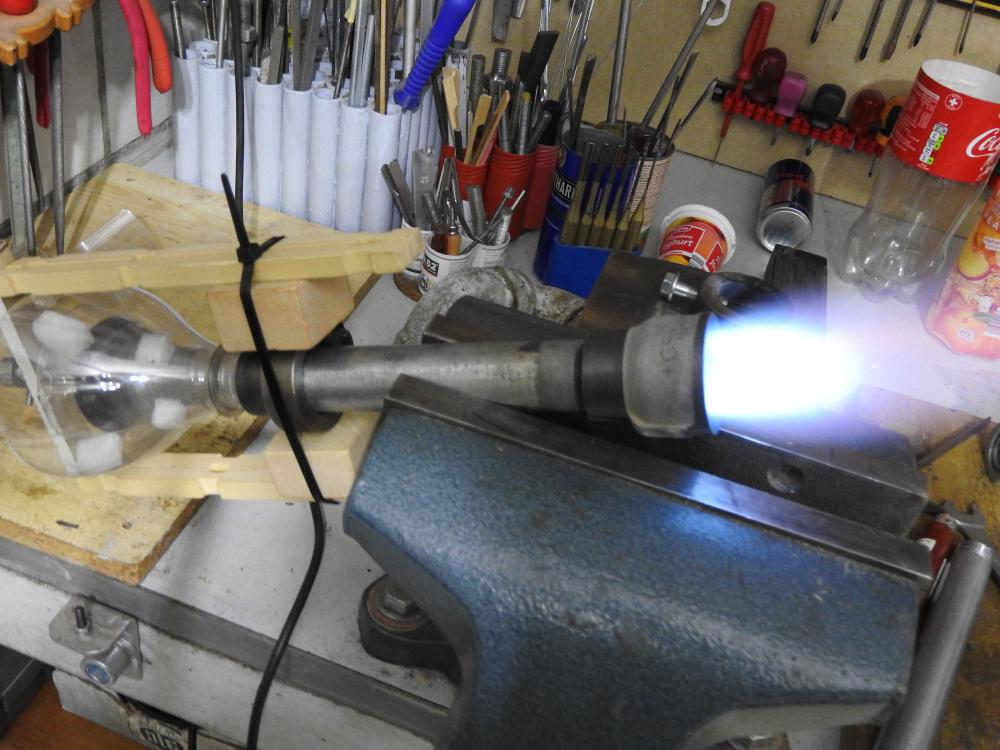

this is the prototype design i came up with:

im getting a good flame with the secondary (or is it primary?) intake completely closed, so there is hope for success in the forge. i like to run my burners at around 45 psi. the orifice is made with a 0.7 mm drill (0.0276") so i guess its around 0.029". im using 96% propane (the rest being ethane and butane) at 900 feet elevation.

what do you think?

-

mikey, thats a very interesting recommendation, but im not sure i really get it. acute angles to the axis of the forge? so 30°? and opposing sides radially, right? and both burners on one end of forge forge?

-

On 1/31/2021 at 7:46 AM, OrganIQ said:

New guy- first post- I have been experimenting with refractory recipes for the last ten years or so- a couple of years after I moved from Northern California to the big island of Hawai’i...

are you saying the gases escape through the insulating rock?

-

its called "nouvelit" and is sold by several diy chains for fireplace repairs over here. im not able to locate the manufacturer. it dries in air, is not hard to cast and pretty strong (flares survive droping on concrete floor from 3-4').

-

just some firecement i found at a local store. it doesnt have a temp. designation. i made thin samples and surprisingly they couldnt be destroyed by the flame, at least not by the flames im getting out of my burners. i even chilled them in water.

(should have been "heat treating" in post above.)

-

-

i appreciate it. so i have to work on my flame, nothing ever gets to white color. its encouraging that the metal will get hotter in the forge.

-

frankenburner, thank you. i am curious what colour a wire has in the flame of your "super-burners". you must have tried that, no?

i dont see how a forge will be hotter than the hottest part of the flame, or will it?

(of course i have tried heating up steel in a forge, e.g. a small one i have carved out of a big insulating brick. it also comes up to orange heat only.)

-

there are so many burner threads i dont know where to post this.

i have a dozen burners. some of them are bought, some i made myself. my burners produce a "roaring", short, blue flame and are fully adjustable for mixture to the point where they go out.

if i take i piece of thin wire and hold it into the flame of any of the burners it gets to bright orange max. against a brick its the same. i guess thats somewhere around 1800°f. a forge cant get hotter than the flame, right? so how does it happen that peopke are getting 2200°f and more and even melting cast iron with propane?

Burners 101

in Gas Forges

Posted

a ratio has no units. a ratio of two is when something is twice as large as something else. a pressure ratio of two means that one pressure is twice as large as onother pressure. if you have propane with a gage pressure of 15 psi the absolute pressure is 30 psi. atmospheric pressure is 15 psi, so the pressure ratio of propane in the orifice of the burner is 2 or 2:1.