Mikishelby

Members-

Posts

30 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Mikishelby

-

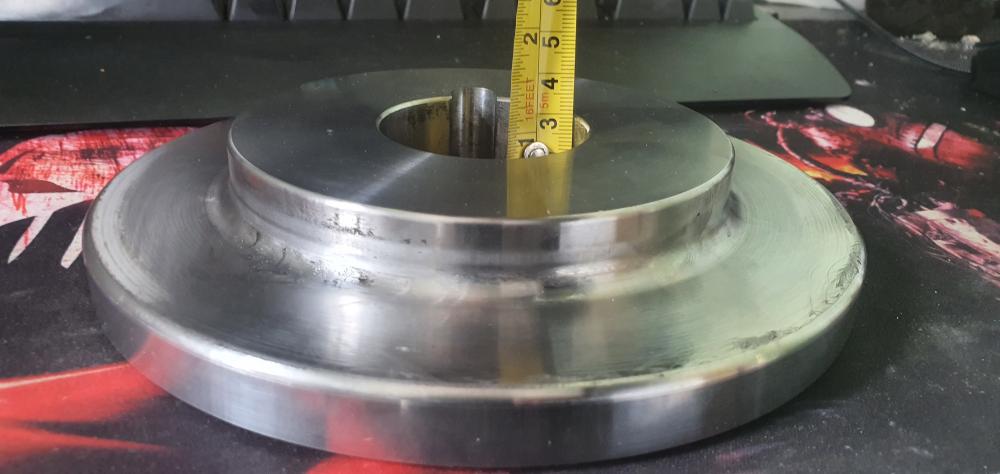

First i need to say this is my first time doing this or attemptiong it, hence all the questions. I was asked at work to harden EN24t its a part for a rolling mashine that another worker milled out . there is 6x in total they were using these already but decided they want to get them harder, so they can last longer. Could you give me advice how to harden it? (I am using a gas forge for this) from topic (problem with forge. Welding temp) I would heat the steel to 820/850°C how long i should keep in in the forge for? do i just quench in any oil? or sould i use something specific then the tempering : what temperature sould i temper it? or should i temper it at all? these wheels are used in rolling mashine for rolling a 60/40mm mild steel box section 3mm thick thank you guys for any advice.

-

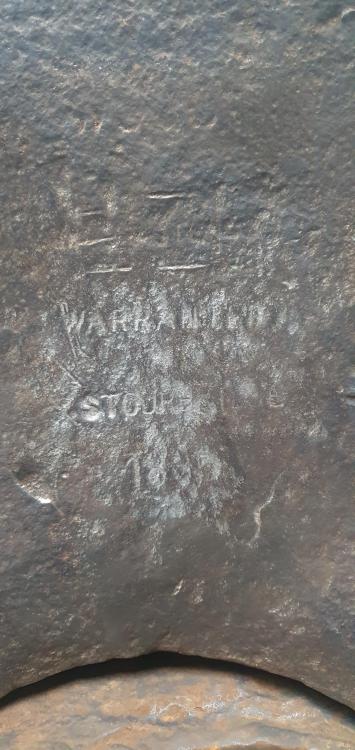

got the baby anvil ii waights 70kg (154pounds) cleaned today and bounce back dropped from 12 inches is 11-1/2 inches consistant so i cant complain about that i found makers and could not find it on google or maybe i just havent looked hard enough. ill post pictures but for what i can readi it say "warranto stourbridge 1885" maybe some of you guys would know something. on friday i have picked up a bigger brother as well and it only have two marks 26 (so probably waight 165kg - 364 pounds) and the other mark is "3" nothing else the bounce back on her is 10-1/2 inches thats great as well both of them sound good

-

Thanks frosty. Will let you know how it went. On my way there now

-

Don't have a ball bearing with me only steel ball

-

-

thats celcius ... 1285 celcius 2345 farenheit is this good? I have not run the forge today focused on finishing the grinder and finally the build is completed. Grinder is all made by myself and my good friend from start to finish, plenty of hours spend on makining it but I am very pleased with how it turned out.. its on a hinge so can flip it down as well

-

got the forge covered with 2 layers it goes up to 1300 o nearly finished building the grinder should have to grinder finished tomorrow

-

___And You are doing great job mate___ really clear explanation and pointers. thanks a million for the advice and will do it right this time hopefully ;D will keep you posted Tink

-

Thanks Tink it was a while since ive got the stuff and then ive red so many threads that i got confused . i have the forge lined up in pure Zirconium Silicate at the moment. red you topic (I've red your topic before but got confused with other topics) and i know i have to buy mirsol x30 from pottery supplies as well, same place ive got Zirconium Silicate. great Tip a while back on trying ulster supplies , Thank you . one thing i still dont understand is Fumed Silica... Do i need it? my forge is completely covered with castolite... no ceramic exposed . what should i do with the layer of pure Zirconium Silicate that i have in the forge at the momment? (rub it off and make the proper mix containing mirsol then apply it?)

-

I just mixed up the powder with water. Had it at almost water consistancy so i could brush it in on castolite with a brush

-

Hello again guys i have put up 2 layers of Zirconium Silicate in the forge. but i think i have done something wrong... this stuff is very easy to rub off, flame itself is peeling it off as well when youll turn the forge on. just add the betonite on top and that will solve the problem?

-

Mikey and Frosty Thanks for reply I have located all the ingredients for kiln wash there is two Sodium Silicate i have found... ~Sodium Silicate 140o TW~ and ~Sodium Silicate 75o TW~ Which one i will need? """"""""""""""""""""""""""""""""""""""""""""""""""""""" so Ill buy: Bentonite Zirconium Silicate Sodium Silicate Thats all I will need? would you know how much of which I will need and what will be mixing ratios and prep for them? Thanks a million. at the momnet Me and My friend are making a 2x72 grinder so not really using the forge at the moment ... would be great to do that kiln wash while it sits idle.

-

would anyone know where i can get Plistix or Metrokite. Location UK If anyone couyld provide me with info that would be much appriciated I got hold of Plistix but its from US and I can't buy a single bag They said I would have to get 5x bags whom is 113kg other than that i had no luck with any of the above and finding rubber stuff for fixing driveways. or when i do find something is out of stock... Mikey can i run the forge for now and make some stuff before i get the ir coating, or should i hold off till ill get that sorted? Thanks

-

Ive got the whole forge covered with castolite what would be the next steps? one more question i i looked at pdf's of casto and there is no metion how to use it what would be a process of drying it? i have done the forge yesterday and ill let it sit for at least 48h before ill start putting any heat in to it, what would be the ideal way to start heating it up to get the cast to set good?

-

Cast o lite just arrived today. im going to make the forge shorter but should i keep just one layer of 2" ceramic blanket or double it? what do you guys think?

-

Frosty I cut it or would i be able to just block majority of it off by forming a wall from ceramic? i have enough ceramic to build a smaller forge probably if i really need to but i would have to check... I thought ive made it too long. when it comes to forge size i had no guides to go by and i tought if i ever will be making a sword or anything of that type i won't have a problem with heating it up. wrong thinking mine is nearly double of your big forge I guess you have a nice workshop sounds fun, do you do it full time? What is : IFBs? and KOL? I have thermomether now and today i have pushed back the burners so they dont stick out and checked temps Forge at around 0.8 bar of gas was sitting at just over 1200celcius 2200F and heated 20 x 20mm (0.78") square bar to just over 1000celcius 1800F

-

any tips? how do you do it?

-

Thanks guys. I've looked hard and finally got a hold of one 25k bag of (kast o lite 30 LI) I am waiting for them to send me Invoice with delivery charge... so fingers crossed I will have it by end of next week. I had no time to do anything with the forge last weekend, it was crazy at work and then i had to change bearing and brakes in the car. Hopefully I will go this weekend and move those burners back to be flush with ceramic. currently as i mentioned before i have 2x 2" ceramic and on the left hand side 2" ceramic with half soft firebricks, Bottom is made of 2" ceramic and 5 Full size soft firebricks... Should I take away the Side Wall Bricks and just wrap the whole lot with extra 2" ceramic on top of what i originally had the forge build? (That would make 4" ceramic on walls and 2" ceramic base with fire bricks) or should i just keep the 2" as i have originally planned when i first build the forge? The forge walls are 920mm long (36"), 330mm wide (13") and 360mm high (14") that gives you inside diameter with 2" ceramic and fire bricks of: 920 (36") long 230 (9") wide 185 (7") high . once i have the burners pulled back in ceramic and forge coated in cast o lite what would be the next steps? just wondering so i can get ahead in case i need to pre order anything, i know you said my burners are out of tune... I so much appreciate all of your advices, Thank you so much for even bringing me to this point.

-

I haven't been able to do anything with the forge this weekend. and I had no replies regarding cast-o-lite30 so I guess it would be hard to get it and the second option might be better. Just one question guys I know I have asked before but do I have to put a hard cast in the forge? I thought that ceramic fibre and rigirazer would be enough... although when i had the forge up for about 3h constantly on i noticed that the rigirzer becomes almost as water and I even seen it drip couple of times from ceramic . if what i have at the moment is not enough, do i have to cover the whole forge with the cast or just bottom bricks would be enough? when i was building forge I sort of went far away from casts because I know they take long to heat up and I knew that I would be using a lot of gas already because of the size of the forge. just asking so I know how much stuff I will order sorry for being stubborn

-

Yeah but you need to be capable to forge weld ;D hence all the questions about my forge ;D

-

I decided to put those burners tilted in the front because majority of videos i had found of hand build forges were close to the front and close together. When i was building the forge my friend that let me use his workshop space for the forge asked me the same thing... at the time I thought I am doing the right thing. when i had looked up forges to buy they had the burners in the centre but the size of them is s lot smaller than the one i had build, I was not sure what size the forge should be for my needs because till now I am not entirely sure what things i would be making hence the bigger forge that i tought i can work with in the future. example, if i need to make it smaller by addning more blanket, as i did already. I haven't done a proper research before. I was finding it hard to find info about it that's why i have based my decisions on videos of others and if i could improve what they did i would do it and that's what i have ended up with. Ultimately I just love The look of Damascus steels and the fact that they are hand forged i think it is amazing how people are making it and it is amazing craft. I cant afford to buy a power hammer but i will be able to make one and then i would love to work with making Damascus myself, making my own stuff. things like chisel, punch, knifes etc

-

I have e-mailed couple of places if they sell Kast o lite 30 as you have suggested.I have found Zirconium for the second option but Cant seem to find Silica liquid commercial link removed Thanks a million

-

Amazing stuff Tinkertim, thank you for your reply and all of the guys replies. I will look in to it and research what I can get regarding coating for the blanket. Im super busy at work at the moment and just back home now . I will let you know what I had found once I do. My posts are super long as well so dont worry about that i am enjoying reading it . The only thing is I had used vitcas ceramic fibre rigidiser. For the coating of the blanket and from what I have found when I started building a forge that this would be enough to protect it and anything else would be an option thats why I never went for cast coating. Fair enough all my info was from YouTube videos gathered up here and there and I tried to take best info and ideas that would suit me to make the forge. Back then I did not even know that this forum existed ... Thank you again guys