Mikishelby

Members-

Posts

30 -

Joined

-

Last visited

Profile Information

-

Location

Northern Ireland (antrim)

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

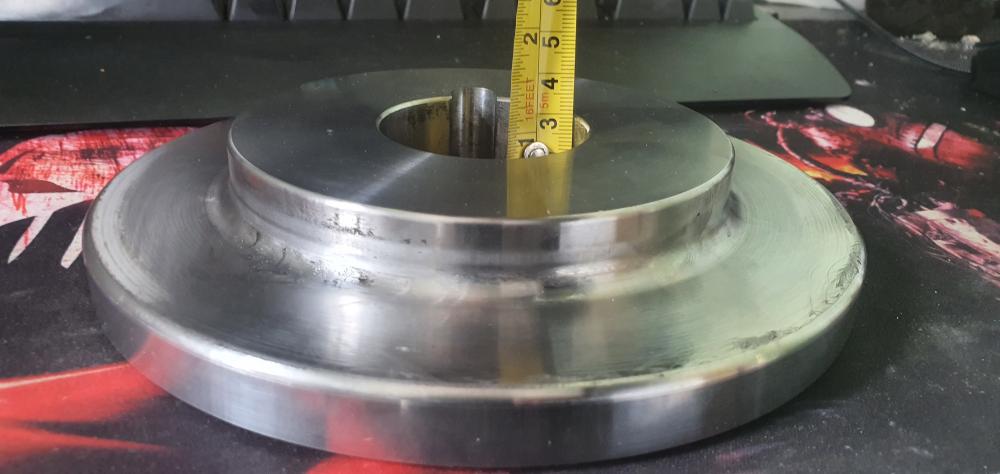

First i need to say this is my first time doing this or attemptiong it, hence all the questions. I was asked at work to harden EN24t its a part for a rolling mashine that another worker milled out . there is 6x in total they were using these already but decided they want to get them harder, so they can last longer. Could you give me advice how to harden it? (I am using a gas forge for this) from topic (problem with forge. Welding temp) I would heat the steel to 820/850°C how long i should keep in in the forge for? do i just quench in any oil? or sould i use something specific then the tempering : what temperature sould i temper it? or should i temper it at all? these wheels are used in rolling mashine for rolling a 60/40mm mild steel box section 3mm thick thank you guys for any advice.

-

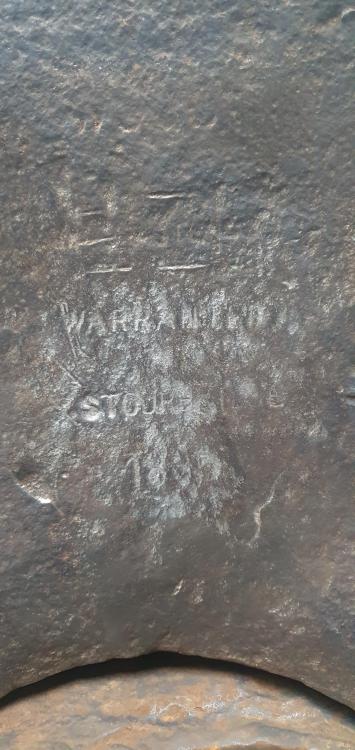

got the baby anvil ii waights 70kg (154pounds) cleaned today and bounce back dropped from 12 inches is 11-1/2 inches consistant so i cant complain about that i found makers and could not find it on google or maybe i just havent looked hard enough. ill post pictures but for what i can readi it say "warranto stourbridge 1885" maybe some of you guys would know something. on friday i have picked up a bigger brother as well and it only have two marks 26 (so probably waight 165kg - 364 pounds) and the other mark is "3" nothing else the bounce back on her is 10-1/2 inches thats great as well both of them sound good

-

Thanks frosty. Will let you know how it went. On my way there now

-

Don't have a ball bearing with me only steel ball

-

-

thats celcius ... 1285 celcius 2345 farenheit is this good? I have not run the forge today focused on finishing the grinder and finally the build is completed. Grinder is all made by myself and my good friend from start to finish, plenty of hours spend on makining it but I am very pleased with how it turned out.. its on a hinge so can flip it down as well

-

got the forge covered with 2 layers it goes up to 1300 o nearly finished building the grinder should have to grinder finished tomorrow

-

___And You are doing great job mate___ really clear explanation and pointers. thanks a million for the advice and will do it right this time hopefully ;D will keep you posted Tink

-

Thanks Tink it was a while since ive got the stuff and then ive red so many threads that i got confused . i have the forge lined up in pure Zirconium Silicate at the moment. red you topic (I've red your topic before but got confused with other topics) and i know i have to buy mirsol x30 from pottery supplies as well, same place ive got Zirconium Silicate. great Tip a while back on trying ulster supplies , Thank you . one thing i still dont understand is Fumed Silica... Do i need it? my forge is completely covered with castolite... no ceramic exposed . what should i do with the layer of pure Zirconium Silicate that i have in the forge at the momment? (rub it off and make the proper mix containing mirsol then apply it?)

-

I just mixed up the powder with water. Had it at almost water consistancy so i could brush it in on castolite with a brush

-

Hello again guys i have put up 2 layers of Zirconium Silicate in the forge. but i think i have done something wrong... this stuff is very easy to rub off, flame itself is peeling it off as well when youll turn the forge on. just add the betonite on top and that will solve the problem?

-

Mikey and Frosty Thanks for reply I have located all the ingredients for kiln wash there is two Sodium Silicate i have found... ~Sodium Silicate 140o TW~ and ~Sodium Silicate 75o TW~ Which one i will need? """"""""""""""""""""""""""""""""""""""""""""""""""""""" so Ill buy: Bentonite Zirconium Silicate Sodium Silicate Thats all I will need? would you know how much of which I will need and what will be mixing ratios and prep for them? Thanks a million. at the momnet Me and My friend are making a 2x72 grinder so not really using the forge at the moment ... would be great to do that kiln wash while it sits idle.

-

would anyone know where i can get Plistix or Metrokite. Location UK If anyone couyld provide me with info that would be much appriciated I got hold of Plistix but its from US and I can't buy a single bag They said I would have to get 5x bags whom is 113kg other than that i had no luck with any of the above and finding rubber stuff for fixing driveways. or when i do find something is out of stock... Mikey can i run the forge for now and make some stuff before i get the ir coating, or should i hold off till ill get that sorted? Thanks