h-m

Members-

Posts

8 -

Joined

-

Last visited

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

finally got my granddads post vise mounted so I can use it. It is a no name 5 inch that is in ok shape. Thanks dad!

-

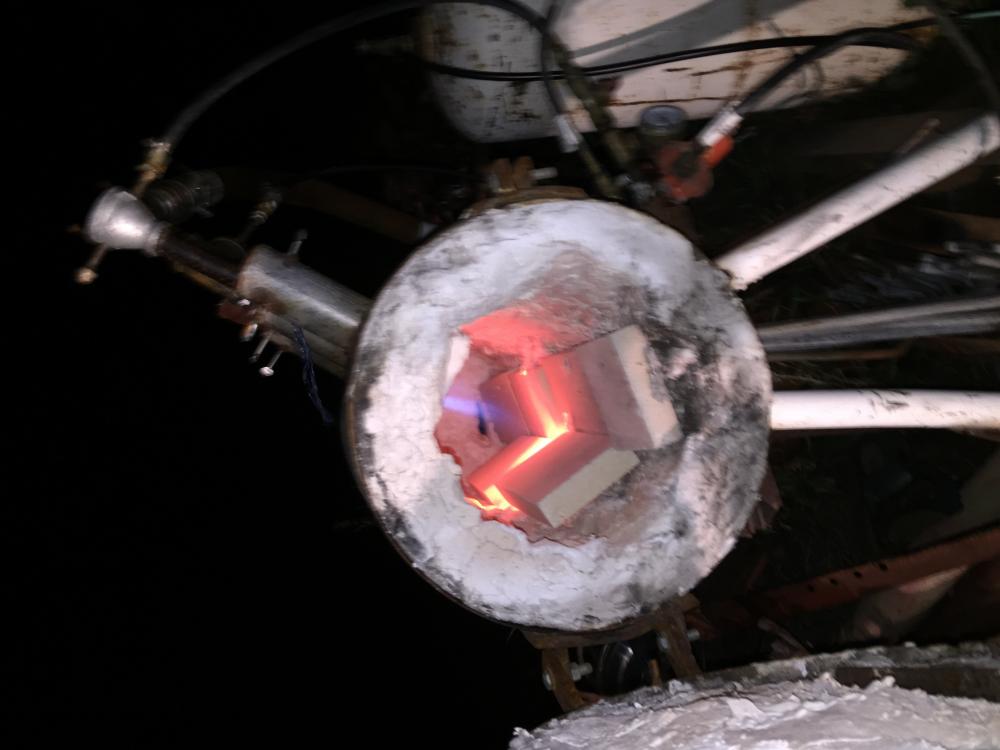

Used this forge tonight for a little while. This burner is great for this combination. It runs good and I can throttle air and fuel down to control heat!

-

ok now i have finally found the sweet combination for this forge. i just put together a new burner again. this one is the cats meow now. 1-1/2" tee, 1-1/2" x 8 burner tube. propane coming in the tee side via a 1/8" sched 80 nipple, not quite 1/2 way across the tee run, hooked up to my wimpy blower, but i throttled it to almost off and cut the propane way down and she heated like a mad man! guage shows 9 psi adjusted way down with a needle valve at the burner. this burner was HOT! i throw 3 of them in there and i will melt the whole thing! now i can get to weld heat the whole chamber so i can weld. tomorrow i will give it a real run on first little project and see what happens. i will get some pics of it running hopefully tomorrow. i will rebuild my regulator so i know that it is working and i should be good to go!! thanks all. micheal

-

Thank you Frosty. Beginners error. First forge. will be making sabers but i realize now most time will be using it for much smaller projects. And I happened to just use stuff I had laying around. It is an old 100 lb lp tank. Thanks all

-

Alright I think I m getting my burners figured out! 1-1/4 tee 1-1/4 a 8" burner tube just straight piece of pipe no flair no bell. Propane coming in side of tee 1/8" schedule 80 pipe secured just at edge of run thru tee. Blower from the power vent water heater running wide open thru 1-1/2 pipe. Gauge says 9 psi lp pressure but I don't trust it. Think it is 1/2 that for real. 1/2" round bar took abt 3 min to get to cherry heat. Much better than I have been doing. Flame seems to burn stable. Think I m getting closer!

-

I pulled the burner tube with the flame holder on end and put a 1" x 6" tube on for burner tonight it burned much better tonight. Still not as hot as I think it should be 1 burner in their and it took about 5 min to get a 1/2 round bar to red heat. It is a large forge though so maybe I am in ball park now

-

thanks Thomas, yes i know that blown don't really need an orfice, i just had the hose hooked up to that supply so i used it, i will probably just pull the tip off and dump the fuel in. i am guessing that that flameholder is actually stiffling my air supply, i kinda thought that when i got done welding it, but thought i would see how it worked, i am going to stick a new piece of burner pipe on tonight and see if that works, sans flame holder, can't hurt right. how much air for a blown burner? i just canabalized this old water heater for its powervent fan, it might not really be many cfm, it is a small squirrel cage, i am going to get an old cloths dryer and cut the fan out of it, i am betting that should provide ample air, saw that on here or abana, can't remember which right now. just basically a work in progress. thanks all.

-

hello all, i am looking for some help on burners in my propane forge, i build a couple different styles of venturi burners and they worked fantastic on the cement block and then i closed the door to my very large forge and couldn't get any heat out of them, backpressure i am sure, so, i went to some blown burners and i have one in there, but i am concerned that it wont make enough heat. i used 1-1/4 x 9" black pipe, 1-1/4" TEE a gas jet with an .035 mig tip stuck in the side, an old blower from a powervent hot water heater hooked up to the run and i put concentric tubes in the middle of the burner for a flame holder, and i seem to struggle to get heat out of it. i hooked this blower up to one of the ventrui burners and i could get heat in minutes, but this one is struggling. do you guys think my blower is too small, my burner tube not the right size, maybe shouldn't have the flameholder tubes welded in the end? what do you guys think, should i go back to 1" for the burner tube, or go up to 1-1/2" or maybe my blower isn't putting enough air over there? i don't know right now, i am thinking of using my venturie burners hooked up to the blower, i suppose that might work too? let me know what you guys think? i will try and get some pics of stuff up here too. thanks micheal