Scooter430

Members-

Posts

21 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Scooter430

-

I got lucky with this Anvil!

Scooter430 replied to Scooter430's topic in Anvils, Swage Blocks, and Mandrels

I honestly mostly frustrated about not knowing what I needed to do to get a good heat in the metal. after reading everything I believe i have deduced what my problem is. the amount of fuel I have on the first is not enough. best heat i every got was in the whole i had dug. which I had a lot of wood on. my daughter picked up the hammer! cold steel but safer that way! -

I got lucky with this Anvil!

Scooter430 replied to Scooter430's topic in Anvils, Swage Blocks, and Mandrels

thanks everyone. been at it awhile now. forge fell off the wood I had it on.. but that has not slowed me down. I have tried many different things to try and get a good pit going, but think I have exhausted all of them. so guess I will go back to my whole in the ground. the fuel I was using is a horrible fuel... pine lumber is the worst. lol barley gets it red, but I have gotten some stuff done -

I got lucky with this Anvil!

Scooter430 replied to Scooter430's topic in Anvils, Swage Blocks, and Mandrels

It worked GREAT! Till I broke it..... Still works just snapped one of the blades off and it is a 7 blade fan so I can't even snap the opposite one off to balance it.... Vibrates A LOT. I did take video of me heating the metal, pulling it out and hammering on it. little worried about posting it though. It is LONG and I would have to probably have to edit the crap out of it to make sure I didn't say anything bade... Don't believe I did because My daughter was in the backyard, but not really sure. Big thanks Frosty! Your post Helped A LOT. I started the fire and let it burn for awhile till I had a nice pile of embers at the bottom. Then I added the fan and the steal! -

I got lucky with this Anvil!

Scooter430 replied to Scooter430's topic in Anvils, Swage Blocks, and Mandrels

I have a 45 cfm 12vdc fan. think that might he enough air. easy to put a potentiometer on to control speed of the fan. -

I got lucky with this Anvil!

Scooter430 replied to Scooter430's topic in Anvils, Swage Blocks, and Mandrels

got bored again today. moved the anvil and built a WOID forge. lol Whole In Dirt. anyway think I used to big a piece of pipe for a tuyere as well as to big a vacuum... did I mention I used old lumber as fuel.... xxxxxxxxxxxxxxxxxxxxxxxxxxxxxx, but I did manage to get the metal glowing red 3 times and beat on it a little. Results of round two with a horribly and uneducated built forge... also used a much smaller hammer. -

I got lucky with this Anvil!

Scooter430 replied to Scooter430's topic in Anvils, Swage Blocks, and Mandrels

I may need to get my thumb looked at as well before I try and forge anymore. Daughter slammed it in her bedroom door. She did not want me to get in... -

I got lucky with this Anvil!

Scooter430 replied to Scooter430's topic in Anvils, Swage Blocks, and Mandrels

MC Hammer. No I haven't. I have been looking at the JABOD threads. Think I am going to make one of those. Maybe to day if the weather holds. I want to try and fuse an old fan from a computer heat sink. Not sure if I can design and print a good adapter for it yet though. Or if it pushes enough CFM to create a hot enough flame. I have a 3D printer. Use one at work too. I am a very weird electrician... Matter of fact yesterday at work I wasn't an electrician at all.... I was a plumber for most of the day but had to make a bracket to hold a water mixing valve. So for about an hour I was a Metal Fabricator.... LOL Had to move the red and yellow signs. Original locations denoted by corresponding colored dots. Installed the orange. Which included tapping into Hot and Cold water lines. Running lines to the wall and down into it. Installing a piece of wood to mount everything to as it is a metal studded wall. Also painted the wood to protect it from mold and rot. Installing hot and cold water valves, making a bracket to install the temperature adjusting mixing valve, drilling a whole through the wall for the drain line and installing that as well... Oh and lets not forget the I wash station sign. Took me all day, but that included going to Home Depot to get all the materials I was going to need.... I don't think 45 CFM is enough air flow.... As my research has mostly shown Hair Dryers and Vacuum Cleaners as blowers used. -

I got lucky with this Anvil!

Scooter430 replied to Scooter430's topic in Anvils, Swage Blocks, and Mandrels

no worries. everyone likes a good story. and that was a good one. -

I got lucky with this Anvil!

Scooter430 replied to Scooter430's topic in Anvils, Swage Blocks, and Mandrels

Thanks Frosty. I read the "read this first" post.... That might be helpful right. I had looked at it before but did not read the whole thing. Must have gotten squirreled by my daughter... Also will read the posts in that post... "Do your research"...... I am failing... -

I got lucky with this Anvil!

Scooter430 replied to Scooter430's topic in Anvils, Swage Blocks, and Mandrels

Irondragon Thank you very much for the explanation and the link Thomas Powers Scooter is essentially my name. It is what everyone calls me. Even my wife. However my real name is James Moore. DHarris Thank you for the tip! So sorry that happened to him! -

I got lucky with this Anvil!

Scooter430 replied to Scooter430's topic in Anvils, Swage Blocks, and Mandrels

Thomas. I am sorry. thanks for the tip. how did I miss use your quote? definitely want to make sure I dont do that again. -

I got lucky with this Anvil!

Scooter430 replied to Scooter430's topic in Anvils, Swage Blocks, and Mandrels

Thanks Tom. that is probably what I will start with as it is the easiest for me to obtain. -

I got lucky with this Anvil!

Scooter430 replied to Scooter430's topic in Anvils, Swage Blocks, and Mandrels

Coal. Propane is Expensive and CNG needs to many parts. Besides I figure if I am going to learn I should learn to do it the traditional way -

I got lucky with this Anvil!

Scooter430 replied to Scooter430's topic in Anvils, Swage Blocks, and Mandrels

so I got anxious and used my torch to heat up a piece of 3/4 rebar. think I did three cycles of heating and hammering. used a 4lb sledge and just to see what a ball pen hammer would do I hit it with that too. think I should have skipped that part. anyway this is what I ended up with. -

I got lucky with this Anvil!

Scooter430 replied to Scooter430's topic in Anvils, Swage Blocks, and Mandrels

awesome Idea. Now if I just had any idea what that was like... did some forging yesterday, kind of. took a piece of 1/2 reber, heated it up with a oxy-acetelyn torch and hit it with a 2"x2" piece of angle iron. does that count? I have heard of Holmdell. New Mexico! that is quite a move! -

I got lucky with this Anvil!

Scooter430 replied to Scooter430's topic in Anvils, Swage Blocks, and Mandrels

Glenn I also dont really know what the Anvil is worth. I did see one on Ebay for 10,500... lol I have no idea if the price they were asking was correct. I am just extremely happy to have such an awesome anvil that has stood the test of time! did the ring and rebound sound and look good to everyone? I may be in New Jersey, but I am from the most southern state in the USA. So southern humor is not lost on me. -

I got lucky with this Anvil!

Scooter430 replied to Scooter430's topic in Anvils, Swage Blocks, and Mandrels

No I haven't. it's not rotted. wires got hit by a semi trailer, which is why it snapped. Figure I whip my chainsaw out and cut it down to size, lag bolt some pressure treated pine to the bottom and put threaded rod through the 2 pieces. i think I would need 8 4x4's bolted together to be the size of the base of this anvil. I don't feel I have read or learned enough yet to know enough to make a solid choice. I will definitely look at that topic. As well as how to make a Forge. I was looking for anything to put the anvil on and when I saw that wood i figured it's big and free! lol Any specific threads you suggest to look at? -

I got lucky with this Anvil!

Scooter430 replied to Scooter430's topic in Anvils, Swage Blocks, and Mandrels

Glenn why not the face? it was going to get rained on so I sprayed the whole thing down with wd-40. including the face. hope I didnt mess up... took video of the ring and bounce. Also ironically a light pole snapped near my house. there was a good chunk of it with no hardware on it that I grabbed. will have to cut it in half and attach it together some how but i think it will make a xxxx of a stand. -

I got lucky with this Anvil!

Scooter430 replied to Scooter430's topic in Anvils, Swage Blocks, and Mandrels

I already have an angle grinder, and a portable oxy acetylene torch. she will just be yell -

I got lucky with this Anvil!

Scooter430 replied to Scooter430's topic in Anvils, Swage Blocks, and Mandrels

George, thanks for the pointers, but.... as far as those other things I could get into... automotive? ooppss. lol. also have a 76 beetle in the garage I have to yank the engine out of again.... fix the 1,2 intake leak I have remove all the tins, take them to work to clean them. paint them, clean up the engine bay, install new engine compartment gaskets and finally put the engine back in. Did I mention the shed?.... I have to finish building that. but my forge will be right outside the door on the side. Did that is obviously getting done first. haha Goods I honestly have not educated myself on rebound and ring yet. so not sure. I did hit it with a hammer to see how well it did bounce. about the same height it was struck with is where it bounces back to. the ring... sounds solid and long. as far as a stand... not really. I have a old paint shaker stand I am using to hold my vise, but I think it is to tell for the anvil. I saw some took a bunch of 2x4s and made a stand by nailing them together. -

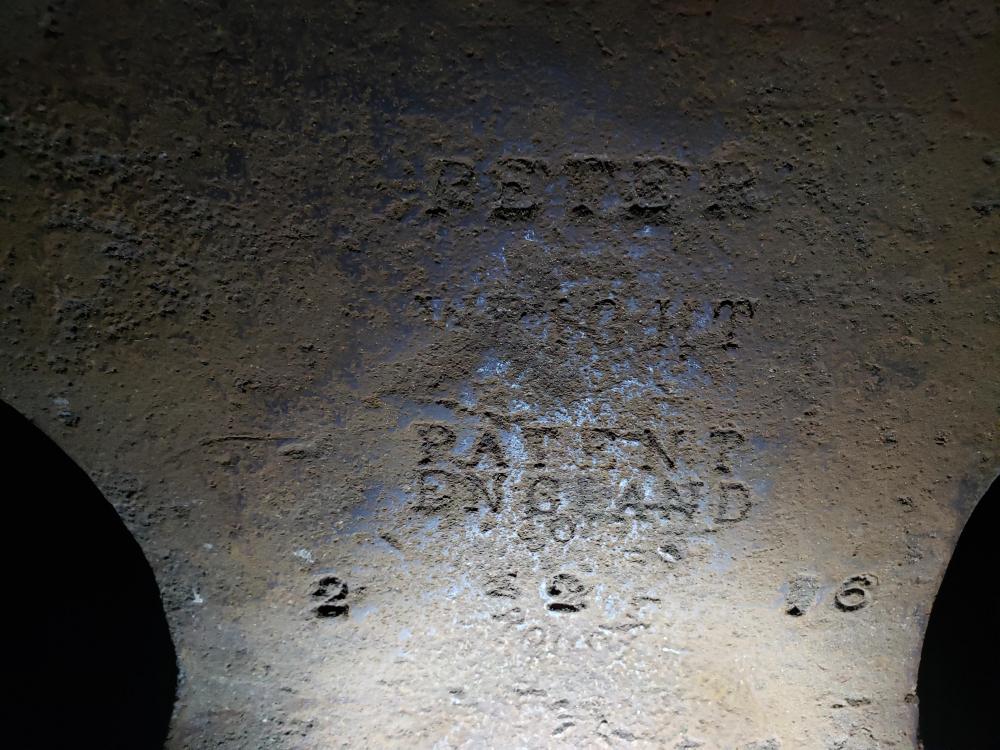

Hi First Post here and hopefully many to come. I have been on the look out for an Anvil for a long time now. I didn't go looking for one, but kept an eye out for one. Man did I get lucky!!! I know I need other tools. I am not 100% sure what they are, but I am pretty sure i can make them! I found is sitting outside among some other metal bits behind my work garage. asked what was the deal with it. few weeks later i was told i could have it. So i grabbed it with a forklift and put it in the back of my truck. at the time the only thing I knew about it was that it was that it weighted about as much as I could dead lift.... about 300 lbs. I wasn't far off the mark. After getting it home and doing some research did I finally learn exactly what I had. Not to mention how fortunate I am! My wife says she is none to happy about it. Does not like the idea of me "stocking a fire" in the back yard or the sound of hammer on hot steel and an anvil, but she understands how bad I want to try this. With a 111 year old anvil, how could I not!