-

Posts

92 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by HumanAfterAll

-

-

21 hours ago, DHarris said:

Is the problem on my end.

Nope, after I posted the images were gone for me too...

21 hours ago, DHarris said:Bolts in a pot, how do they not get permanently fused?

Yeah, that's what I'm currently thinking about. I could go and remove that small "pipe bevel" (IDK how to call it) and make the whole thing touch the bottom plate, or I can weld four big hex headed screws on the under side of the bottom plate - thus not needing to remove the bevel on the tuyere and making the screws head's act as an spacer. IDK which approach would be better, but the former sounds safer.

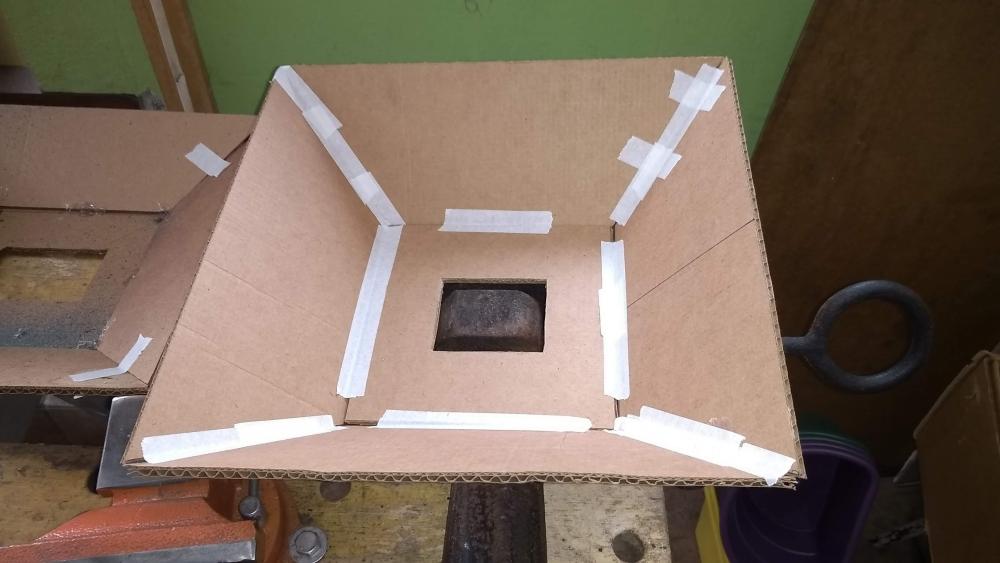

Also, I went ahead and made another model a bit more like Bob's design: 3 1/2" deep but with sizes adjusted to my tuyere. Here's how the model looks:

I had a company cut the whole thing down on 1/2" plates for me:

Don't judge my welding

I'm still figuring out how I'm going to cut that square hole on the bottom plate. I'll probably try with my angle grinder, but it might turn out bad. The alternative is having another nearby company plasma cut the piece with the hole for me.

I'm pretty happy with the result. Seems very sturdy even though I eyeballed most of it (as I have almost no tool to weld stuff).

Cheers!

-

Brush wire to the face sounds tempting when beard is growing, I get you, DH

Anyway, the anvil's face is not that dirty, Frosty, not as much as the rest of it, but if there's no problem, I'll go with a straight wire brush which is a but less "offensive".

Cheers all!

-

Found some more listing of this same model here... We have/had some French rail companies here and during the Brazilian "Belle Epoque", we had a lot of influence of french culture (thus the name).

Want to clean mine up a bit and then get some carnaúba wax on her.

I think I'll wire brush the whole thing, but what about the face? Is it OK to wire brush the face?

Cheers!

-

Hey, guys.

So, two thing.

First, this is the solution I found to avoid the large gap between the ball and the side of the pipe:

What you think?

Also, the model I made looks like this:

It's about 2 1/2" deep. What you guys think?

The steel plate the seller has available is 1010, 1020 and A36. Which one should I go for?

Cheers all!

-

7 hours ago, Frosty said:

I think it took a while to sink in that FIF is entertainment, not educational TV.

Still. I get pretty bothered when someone reaches out to me and goes like "man, look at what this guys are doing! It's crazy. It's awesome". I politely say that it's nice and try to show them some really beautiful video on the subject.

For those who come to me about knives, I share this one:

Really love it.

6 hours ago, JHCC said:Originally filmed in 1978 as one of a series by the Sheffield Polytechnic:

This is gold. Pure gold.

6 hours ago, JHCC said:And finally, a wonderful (if wordless) film of the finishing and assembly of scissors

Watched this about a month ago. "Wordless" is a good description. Made me a little emotional too.

This all is what I understand as the real beauty of the craft. Not what's sold on TV shows...

Thanks for sharing all this, guys. Thanks a lot.

-

Thanks a lot for all the inputs guys.

Because of the language barrier I face some difficulty visualizing everything you guys describe, so if you're able to and it's not much work, I'd really appreciate whatever pictures you guys think would be nice to share.

The first thing I though before your post was putting a plate over the opening to reduce the hole diameter. Something along these lines:

But now I'll give some more thought to what you guys shared.

Once again, thanks a lot!

-

Unfortunately the coke that I buy here varies a lot of size. Sometimes is small, like 4-5 mm, other times it's quite large like 20-30 mm...

Would you mind sharing some pictures of your firepot + clinker breaker?

I guess I'd have to go with trial and error...

Cheers!

-

I'm more concerned about the space between the ball and the tubing. Seems a bit too large...

When looking at other examples, I can see that the distance is smaller, avoiding coal/coke falling through.

Some examples I found on Google:

Does it make sense what I'm thinking?

I'm honestly asking because I really don't know much about firepots.

Thanks!

-

29 minutes ago, ThomasPowers said:

perhaps you have heard of the Romani one about the "fourth nail"?

Please continue!!

-

2 hours ago, anvil said:

Check the size of a clinker ball from centaur forge.

they say commercial link removed that it is 2-1/2" long with a 2" wide flat face.

Following those measurements, mine is 2 3/4" long but has no flat face. The shape is different.

I'm not sure what I should understand from looking at theirs.

Thanks

-

So I was looking into some designs and I settled with Bob's, then I took a second look at my tuyere and the think is large...

The top opening (where the clinker breaker is located) is 4 3/4". And from the distance between the fixing hole (diagonal) is 6 1/2". I think that if I leave it like that, most coke will fall through without even getting a heat...

This a really big opening, isn't it? I don't want to leave this tuyere aside. What can I do to adapt it to a firepot design like Bob's?

I thought about having a plate that would fit between the tuyere and the bottom of the firepot, to get rid of the distance without stressing the parts and then have the bottom of the firepot have a smaller hole; We'd only be able to see a small part of the clinker breaker.

-

Thanks!

-

Now actually related to this topic. I disassembled the blower, gave it a good cleaning and painted it:

I love hammered paint.

Now I'm struggling with the firepot dimensions. I don't know which way to follow.

-

Hey, guys. Sharing how it looks now:

-

Just realized I posted at the wrong topic.

-

Have you ever had someone ask you if you made swords just because you're a blacksmith?

How do you take this kind of misconception?

-

You'll see that the smaller parts are cleare than the other. That's because those parts where cleaned on vinegar as well.

Used carnaúba wax to finish it.

Cheers, all!

1 minute ago, Frosty said:Looks good, almost too good to get dirty again.

Carnaúba makes it feels like it's really protected. Let's see how much time until I need to rewax it!

Thanks for all the tips!

-

-

Hey guys.

So I want talk about how the blacksmith seems to be perceived for those that do not have contact with a professional blacksmith or simply only know the craft from TV shows and movies.

I found a thread related to what I want to talk about, but it's dead since 2008 and that's why I'm starting a new one. See note

It seems, to me, that people generally perceive blacksmiths as weapon-makers and I think that movies are to blame for that - the magnificent artistry of the craft is basically never present on movies. Most of the times we simply see the "blacksmith" hitting a piece of hot metal like this trying to break it in half and that's that...

TV shows seem to contribute to this a lot too... You can take a show like "Forged in Fire" and all the aesthetic revolves around fire, sparks, brute force, tattoos and heavy metal music. Just look at their marketing pics. See, I'm not trying to judge the quality of the stuff being produced by the professionals on the show, neither am I trying to say that the professionals are unqualified or don't know what they are doing.

Obviously there's nothing wrong with heavy metal music and tattoos - that's personal - and there actually are sparks, fire and brute force on a blacksmith shop - it's just the case that these are not the things that defines the craft IMO.

What I want to know is what you guys that are on the craft, that live from the craft and that know the craft inside out think about all this.

I also believe that this misconception about the craft is stronger here in Brazil, as blacksmithing was never a big part of our culture. You can get to Instagram and check some really awful examples of what the blacksmith/bladesmith aesthetic looks like... I could give some examples, but that would not be delicate of me.

For me, this whole heavy-metal-long-beards-sparks-and-flames thing just does not fit. What you guys think about this?

Mod: This has been merged with original post, there is no reason to have more than one thread on the same topic

-

6 hours ago, Frosty said:

The square hole in the side that is connected to the hardy hole in the face is to allow punched slugs and cut off pieces to fall through and out. If a bottom tool say a swage jams in the hardy hole you can use a chisel like a wedge through the side hole and under the jammed shank to loosen it and get it out.

That's a really elegant solution.

6 hours ago, Frosty said:If you ever visit Alaska I'd sure like you to give my beloved Soderfors anvil a try so you can compare. If I ever get to Sao Paulo I'd love to try that beautiful lady of yours.

I'd love that, Frosty. Thanks for being so receptive!

I work at a company that's based in Seattle. If I ever go over to our HQ, I'll check if I can spend another day or two over and fly to Alaska.

And yes, if you ever come over, please let me know.

6 hours ago, Frosty said:If you get the chance try out other anvils so you understand just what an outstanding anvil you have.

I could compare she to my anvil-shaped iron object, but I don't think it would be fair.

Cheers!

-

Thanks, guys!

Yeah, Frosty, it was very worth being patient!

23 hours ago, Frosty said:she's cast Swedish steel!

I thought she had a steel plate welded, by looking at that top part on this picture:

\

\

Another question: what type of tool can be used on that side hardy hole?

-

Hey, guys! Here she is!!!

One thing that I did not see on the picture the previous owner sent me is that the flat horn tip has been broken (or maybe cut off).

It's possible to see some rust spots on the face and what I believe is a welding spot; maybe some attempt at repairing?

Lot's and lot's of chisel marks. This girl has been used a lot, I believe, but the table is near mint.

Also, she is heavy. It took me and another guy to take her out of the trunk and I can lift heavy stuff... In the past I did some weightlifting - today I still lifting weights, which basically means lifting myself from the bed every morning

IDK how much does it weight and I'll probably don't know for a long time, as I don't have a place to weight it.

IDK how much does it weight and I'll probably don't know for a long time, as I don't have a place to weight it.

Overall I think I've made a great deal.

Oh, rebound is around 95%

What else you wanna see?

Cheers all and thanks a lot for the patience and helping me chose an anvil!

-

Copy that, sir!!

-

I've asked for a video of it, but I don't think it's busted...

I'll pick it up at a local police station on Saturday or he'll bring to a nearby police station in my city (we're about 70 Km away)

Fire pot dimensions for coal forge

in Solid Fuel Forges

Posted

Because of the gap between the tuyere's pipe and the clinker ball... stuff will easily fall through, I guess. But maybe that's just something that I'm afraid will happen and, as Thomas said:

This might be the simpler solution.

And yes, I'd really some input from the guys who know what they're doing, unlike me, regarding connecting the tuyere to the pot...