Sploing

-

Posts

11 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by Sploing

-

-

It is indeed.

-

Slight update. It’s 4kw not 4hp

Also I’ve worked out I just need a fairly simple switch to control the solenoids.

The issue I have is that I will need a 240V VFD to power the motor but the solenoids require 24v DC so I’m going to need a way to power both

-

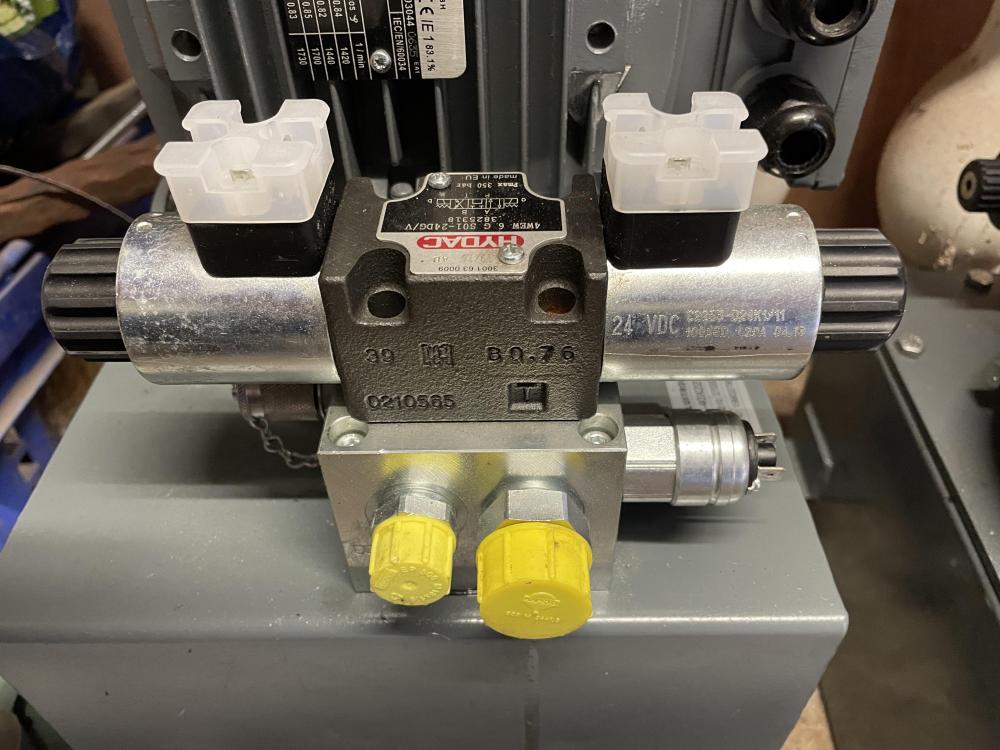

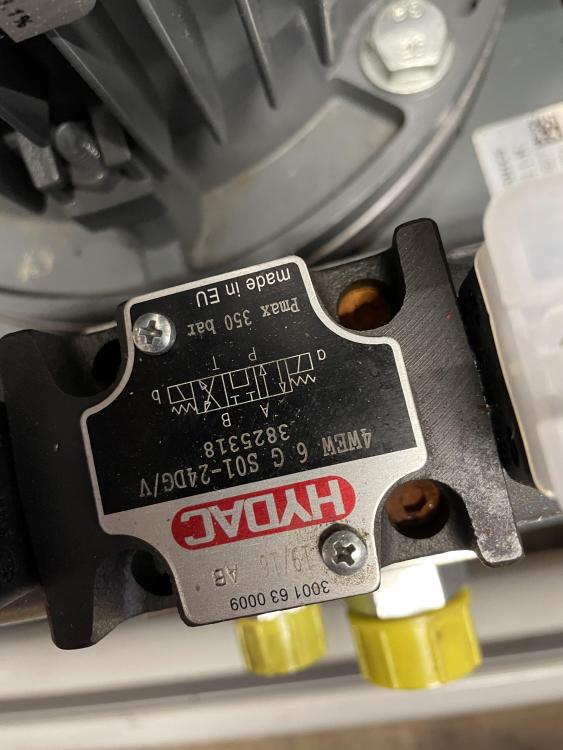

I’m in the process of collecting ring the parts I need to build a hydraulic press and managed to pick up a couple of hydraulic power packs in great condition for next to nothing.

the one I’m planning to use is a 4HP 3 stage fluitronics unit which has hydac solenoid control valves fitted.

Hydraulics really isn’t my strong suit and I’m learning as I go.

I’ve attached a few pictures but have some questions I was hoping somebody with a little more knowledge could answer.

- I was told the pump is rated for 250bar and 19 litres per minute, is there a way to confirm this and will it be enough. I’m looking for enough ram speed driving a 4” ram with a 2” shaft.

- Do I need to control the press using the solenoids or can I bypass and use a regular hydraulic control valve?

- I know what connector the solenoids use, is there a simple standard controller I can plug in?- Anything else I should know before I start planning this project in detail?

thanks,

Sploing

-

Thanks everybody.

I think I’ll hold off on on “repairing” and get some 10mm plate with a hardy post for flattening.

Was I right about the construction by the way?

-

I’ve been using my anvil for around 2 years now. It’s one I bought second hand without really knowing too much about it at the time.

It has no maker’s mark, a protrusion on the side I have been told was used for making carriage clips and comes in (as best I can tell) around the 360lb mark.

It has square handling holes at the waist and I think I can see a feint clone around the face making me suspect it’s wrought with a welded face.

unfortunateky it has about 2.5mm of sway at the worst point which is causing me a few issues getting things flat and when welding multiple bars together (I mostly make knives)

Can anybody tell me if it’s possible (or even worth) repairing this either by removing material or adding to the face with weld? (I know it’s not as simple as that)

many thanks

-

Many thanks for all your responses and sorry it’s taken me a while to reply.

i think the most likely issue, what what I’ve read, is going to be temperature so the plan is to use a pyrometer to tweak the forge to the point that it’s capable of producing high enough temperatures

-

So I’m a fairly new blacksmith, self taught and I built all my own equipment including my propane Venturi forge.Things were going pretty well until I tried my first forge weld and I just cannot get it to stick, and I’ve tried a bunch of times. Here’s my method, hopefully one of you can tell me what I’m doing wrong:

I take 2 squares of 6mm mild steel and clean the faces on the grinder using a 36 grit belt until they’re flat and shiny. I mig weld them together

Throw them in a preheated forge and let them get cherry red then take them out for a quick brush and a sprinkle of sodium tetraborate decahydrate around the edges. Back in the forge until white hot then out again for a few light taps with the hammer, more borax and back in. Out again when white hot for a few more (slightly heavier) taps with the hammer then left to cool.

I’ve attached a picture of the ‘welded’ faces of my last attempt to give a little more info, any advice greatly appreciated. Thanks

-

On 9/13/2019 at 1:27 PM, Sploing said:

It’s in the UK, I picked it up a few weeks back but haven’t had chance to clean it. The bounce and ring are superb. There’s no way a set of bathroom scales would help, I’m a fairly big guy but I can’t lift it! i had wondered what the little projection was for so thanks!

Well, I cleaned it up and there wasn’t a mark in sight.

A plank, some scales and maths (thanks guys) showed it to weigh 360lbs or 3.0.24

-

It’s in the UK, I picked it up a few weeks back but haven’t had chance to clean it.

The bounce and ring are superb. There’s no way a set of bathroom scales would help, I’m a fairly big guy but I can’t lift it!

i had wondered what the little projection was for so thanks!

-

Carriage maker’s anvil

in Anvils, Swage Blocks, and Mandrels

Posted

I found some faint markings on my coach maker’s anvil today after owning it for a few years

I can faintly make out 3 0 18 making it 354lbs by me reckoning which is roughly what it seems to weigh, these are the only markings I can see on the thing

I’d love to know more about who made it and when if anybody can shed some light on it