B3NDY

Members-

Posts

12 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by B3NDY

-

Anvil Identification and use of shelf?

B3NDY replied to B3NDY's topic in Anvils, Swage Blocks, and Mandrels

Thanks for all the help! Quick update, I picked it up the other day and after a lot of huffing and puffing managed to get it to my shop. Iv attached some pictures showing the condition. Seems the numbers are 3,3 and some double digit number (possibly 20?) so about 420lbs/190kgs + 10-20lbs!!! Not sure what the badge is at the bottom, very worn so couldn't make out any text. The face is fairly rough and has a bit of sway but nothing too major! Cant tell if it has a steel top, I think I can see some seams but hard to say, has about 50-60% rebound with a ball bearing either way so not bad. Some nice sharp edges and really can't complain for £350 considering the size! Given it a good wire wheeling and a heavy coat of BLO for the time being since it will be outside. Quite the upgrade I would say! Any further advice on how I could clean up the face? I know I shouldn't take a grinder to it but do you think it will clean up at all over time or is there nothing much to do? -

Anvil Identification and use of shelf?

B3NDY replied to B3NDY's topic in Anvils, Swage Blocks, and Mandrels

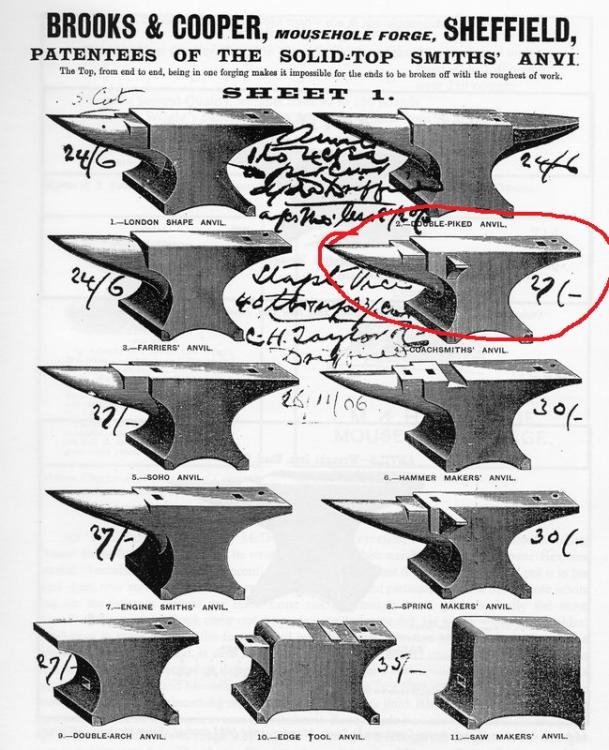

I think you might be right about the mousehole suggestion if you compare to the advert attached! Pretty cool considering I live about 20 minutes away from Sheffield UK! Is this a good thing? I know they're some of the older makes, anyone know if they had any issues? Does the solid top it mentions refer to a hardened steel face do you think or simply a solid piece of wrought iron? I will be viewing on Wednesday, will make sure to remember a bearing, small hammer and brush! And don't worry, I will only be taking a wire wheel to it, nothing more! -

Hi, I am looking at buying this anvil pictured below. Very reasonable price for the size and the face/edges looks in good condition (Slight sway in the face). I was wondering what people thought of the condition/manufacture, from what i've heard it looks like a Peter Wright with the flat edges on the feet? Also any estimations on weight? Cant see any markings but is 91cm long for reference. Second point, any idea what the use of the small shelf is? I know usually when they are flush with the face it is useful for scroll work but is seems odd that it is lower down than the main face? Thanks for any help

-

Hi, so Iv been using a waxy finish for a while and it's alright for batch work because of the minimal residue, and if there is any it's not oily once it has set but if wanted to check out how BLO looks since it seems to be very popular. My issue is firstly I tend to get inconsistent results with it, some parts blacken a lot with a matte look while other parts seem to go to a glossy black, I'm guessing this is due to different temps but what should I be aiming for? Also I tend to find that by rubbing off the residue, the highlights from wire wheeling the edges of twists end up rusting quite quickly, even inside. Is there any way to help get the finish to stick to these highlighted edges which are almost base metal by that point because this has been an ongoing issue for me. Thanks

-

Blowtorch capable of heating rivets?

B3NDY replied to B3NDY's topic in Welding/Fab General Discussion

Thank you, and yes when I say rivets I mean tenons, is it correct to say you rivet a piece together when setting tenons or is there another word for it? -

Blowtorch capable of heating rivets?

B3NDY replied to B3NDY's topic in Welding/Fab General Discussion

Yes you'd be correct, probably should have used this picture without logs to give a better view. Appreciate the compliment, only been doing this for a couple of summers in between uni and with my little shed its hard to get set up for production, very surprising how different it is from general experimantal and one off items. I've seen F-clamps used for larger spans but I don't know if they can be too flimsy for heavy clamping? Is it best to stick with the G-clamp style? Cheers -

Blowtorch capable of heating rivets?

B3NDY replied to B3NDY's topic in Welding/Fab General Discussion

There is a picture of the holders below, as you can see its not impossible to rivet it together as I have already done it both at the anvil and in a vise but It would seem using a torch and the vise would make the job much easier and faster in the future. Trying to hold all the parts together when im setting the first few rivets while keeping everything tight and straights is just such a pain and I think the time saved would be worth it if I'm trying to make a few at a time. Thanks for all the suggestions, may have to wait untill i've sold a few more items but I think spending the extra cash on a good oxy/propane torch is the way to go! -

Blowtorch capable of heating rivets?

B3NDY replied to B3NDY's topic in Welding/Fab General Discussion

Thanks for the help, I think I'll have to head down the route of an Oxy/Propane torch at some point then. This seems to make the most sense as I am planning on making a propane forge too so saves having to buy more bottles than I need. The items I'm riveting together are some heavy, sturdy looking log holders that I plan on selling if the demand is there just to fund my projects. Each needs 8 rivets setting but the issue is more that all 8 parts that make it up need to be held together so keeping it clamped up in the vise would be a major time saver and much less of a pain to assemble. -

I have made a few things using mortise and tenon joints but when if comes to larger items it is a lot of work to move the whole, partially assembled, piece over to the coal forge and back to the vise just to set one rivet. I have been looking at getting a torch to help with this and was looking for some guidance as to the capabilities of different types. I cant afford a large setup so was looking at a simple bernzomatic style of torch. Does anyone have any experience trying to set rivets with these smaller torches? I usually use 10mm round tenons as I have the tooling for it but I dont want to buy a torch, only to find it cant heat this up enough. Thanks for any help.

-

Hi, I was wondering if anyone could help me identify whether this anvil is cast or forged? Also if there has been a plate welded onto the top? I was plan on cleaning up the bumps on the face after buying it as it is fairly flat overall but don't know if it's worth it with if it's cast iron. Fairly new to this but I thought the texture on the top looked cast but then it seemed to have handling holes in the sides so I just don't know. I can try listening for a ring and looking at rebound but it's an hour and a half away to pick up so id rather know before hand. Thanks for any help. Iv attached some pictures for reference!