-

Posts

22 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by sidewinder81777

-

That's incredible

-

Imagine the hammer I'd need lol

-

Wouldn't that be a sight

-

-

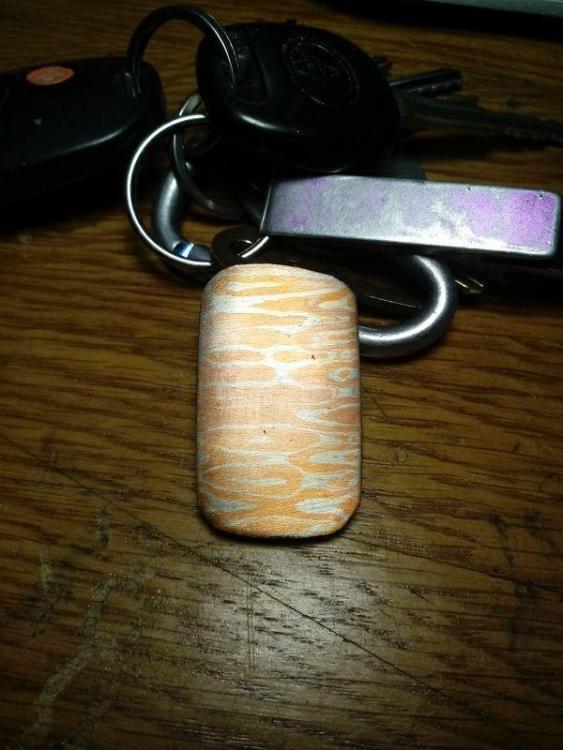

So I took the 2 stacks of 9 quarters I Welded at the end of my last thread and welded them together and made this billet. I think this is probably the coolest thing i can do in my little micro forge, but bigger things are on the horizon.

-

-

Did a quick etch in straight muriatic watching it the whole time. Dumped it in the pool when i liked the look lol.

-

So where can i find information on comparative metal etching rates. In this case specifically copper and nickel

-

Well i already have muriatic acid on hand and im not squeamish about chemicals whatsoever so do I dilute it or use it straight? And any reccomendations on time?

-

That's what i was thinking too. What would be the best way, ferric chloride?

-

-

If you actually look at the photo album on that link which details the construction of that forge they most definitely satanited the crap out of that kaolwool. but I definitely appreciate all advice and I'm married to any particular idea yet. I just think it's a pretty neat forge lol.

-

oh ok the one i was looking at ia actually a saw ammo can, they're 6 3/4 wide. I was looking at this build

-

Yes and it's in the works, planning on a 50cal ammo can forge in the near future. I figure that size should serve my needs for a good long while until I'm good enough to make swords. So yeah a good loooong while lol. And definitely need a heavier anvil like object or if i get lucky an actual anvil. The little piece of plate I'm using now is way too light for much beyond jewelry sized work.

-

When i have a forge large enough to accommodate a clamp I'll use a clamp lol, for now with the tiny one i can barely get a tall enough stack of quarters for a pendant sized billet as it is.

-

I'm very new to smithing in general but quarter mokume sounded relatively easy so into my little micro forge a stack of 8 went. surface prep was a scrub with steel wool and an acetone bath, I did't use any kind of press just pulled the stack out with a pair of needle noses when they started to sweat and gave them a couple light whacks. The first heat the top and bottom quarters didn't stick so just did a couple reheats until everything was nice and fused. then ground the edges and just stared at the billet for a few days contemplating where I wanted to go from there. thought of restacking a couple times to bring the layer count up but dropped that idea and just shaped it up and ladder patterned it at 24 layers. should make a nice pendant.

-

Excellent, it's at 24 layers now so will probably stack it a couple times to get it up to 96 cause why not. Will make it look better when i ladder it. Hopefully i still have a usable amount of material when I'm done lol.

-

I may draw it out into a longer bar and cut and stack a few times to get the layer count up before I ladder it. I understand with coin stacks you don't need to flux for whatever reason but does that still apply after the first weld. If i cut and restack or hot cut and fold will I have to flux at that point or is whatever magical quarter properties that applied in the first weld still active?

-

Thank you everyone. And frosty I haven't done anything else with the quarter billet yet but I plan to ladder pattern it. I'm pretty sure I'll still have enough material left after that for a pendant.

-

Oh well didn't cost me anything but time really. And every failure is a lesson learned. I'll use it until it fails then do something else lol. After all it's just a dog food can.

-

Thank you! We have 4 pallets of perlite aggregate at my work that we got years ago for a project that didn't pan out. I actually scooped a few handfuls from a broken bag off the floor and mixed that with plaster of paris as an experiment. It seems to be degrading fairly quickly though around the point where the torch flame hits the side of the forge so I'll definitely be going with a different solution when I make a larger forge. probably just a soft firebrick lined steel box.

-

My name is Josh, I'm 41 and from Jacksonville, Fl. I've been interested in blacksmithing for quite a while. Between watching forged in fire and man at arms and Alec Steele vids lol. I finally made myself a little micro forge out of a large dog food can and started playing around with some stuff on a small scale (jewelry mostly) with a decent degree of success. just today I was pleased to discover that though there is no way my current tiny forge is going to get to welding temp for steel, it WILL get hot enough to weld a stack of quarters, so I'm kind of over the moon right now over my little pendant sized mokume billet lol. Can't wait to scale up and start doing some bigger stuff!