-

Posts

4 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by savage_sultin

-

-

-

thanks, regarding the "3a. Pro tip #1: When doing your research, don't bother with the Search box up at the top of the page; it's pretty worthless. Go to google and include "site:iforgeiron.com" as one of your search terms." thats pretty much what I used but checking out google now. thank you im navigating through the site now, ive been forging for a while but just switching from Venturi to a ribbon burner

-

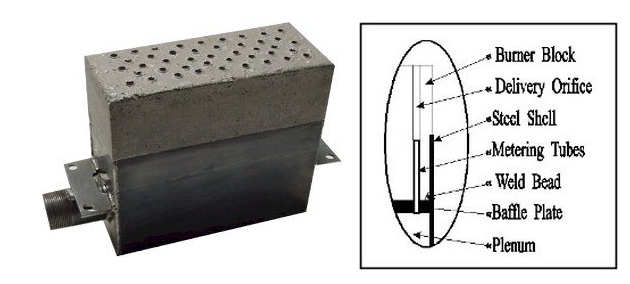

Hey folks, im new and this might be discussed before but when I searched I didnt see my question. im making a ribbon burner and for the holes im going to use stainless steel straws cast into the cement. would you think they would be fine? I dont see them being an issue, seen the pine ridge burner and they use a steel metering tubes

Ribbon burner design

in Ribbon Burners

Posted

Ok thanks. I wasn't sure if the cooler air would keep it cool. I think ill keep them short