Jimmies

Members-

Posts

34 -

Joined

-

Last visited

Profile Information

-

Gender

Male

-

Location

Yorkshire UK

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

Plenty of belts available and they seem to be around £14 for 2

-

Hello All and Happy New Year I'm just looking at a grinder and like everywhere else a 2x72 grinder is alot but this is 6x89 with a 2.2kw ( 3hp? ) motor axminstertools.com at2260bs2 belt sander What am I missing Cheers

-

Thanks Both....I'll get hunting

-

I can't find plistex or itc at all here in the UK online

-

Apologies... I've checked the tub and it is castable refractory.... Is that a better/correct covering for kaolwool

-

OK, cheers Mikey... What should be used on top of kaolwool? I will be looking to build a smaller forge as this one is quite big for 1 burner

-

What should I have used instead of refractory cement... From what I remember that was the suggested covering for kaolwool I'm happy to resolve issues and appreciate any help

-

Hello Mikey At present the forge gets to 1010 deg C at an indicated 5psi....then the plastic at the near end of the probe gets soft. The gauge will go well over 20psi fully open so I would imagine that it will get hot enough.... I'm nowhere near thinking about forge welding anyway. What heat resistant coatings are you referring to and what would it do for me. If I remember right there are two wraps of 1 inch kaol wool with refractory cement... It is very hard and stable

-

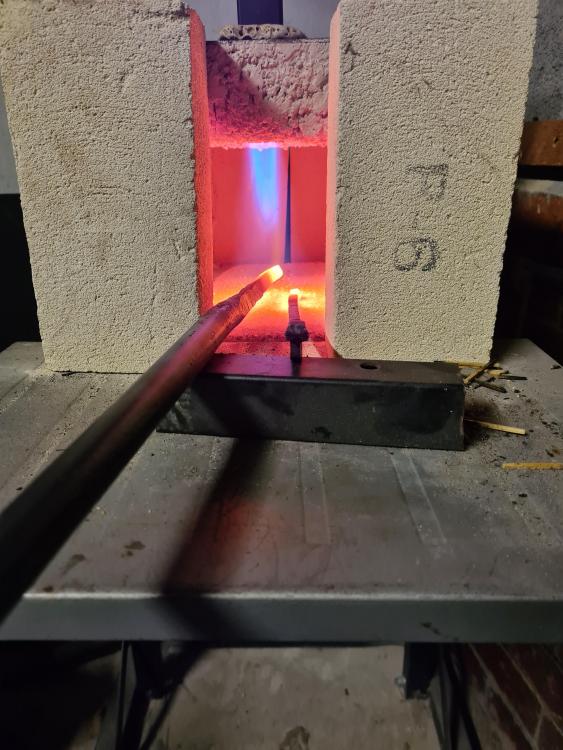

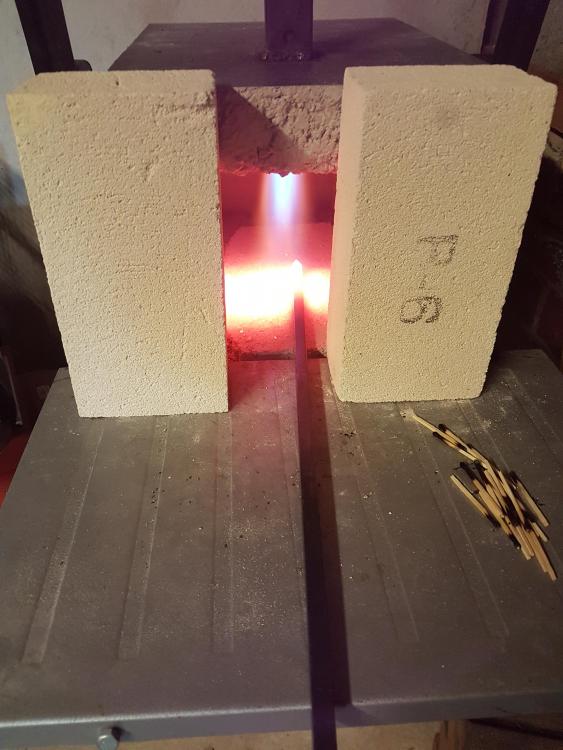

I actually made the forge and burner a while back (two years).... Bought the anvil at the same time... Then kids and work got in the way. I'm hoping to find the time to get this hobby moving but I'd like to start with the burner and making sure it is setup fairly well. I bought an Amal burner after not getting on well with a homemade version. Pics attached and any thoughts greatly appreciated

-

Hi Frosty It was the edge of the cross pein that was making those marks...and yes it was completely by accident. In fact I was going to ask if I should round off the edges of the pein to remove the errant strikes...but I guess as you say once I start to learn some control it will give me more possibilities of texture

-

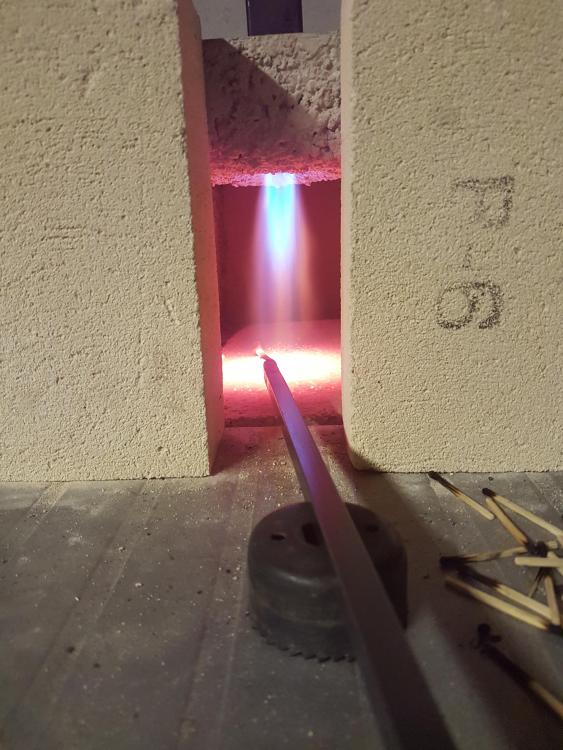

This is the flame earlier when I had a good heat in the forge after 10mins of ignition. I've yet to run it at full whack yet...this was it at around 2 or 3 psi

-

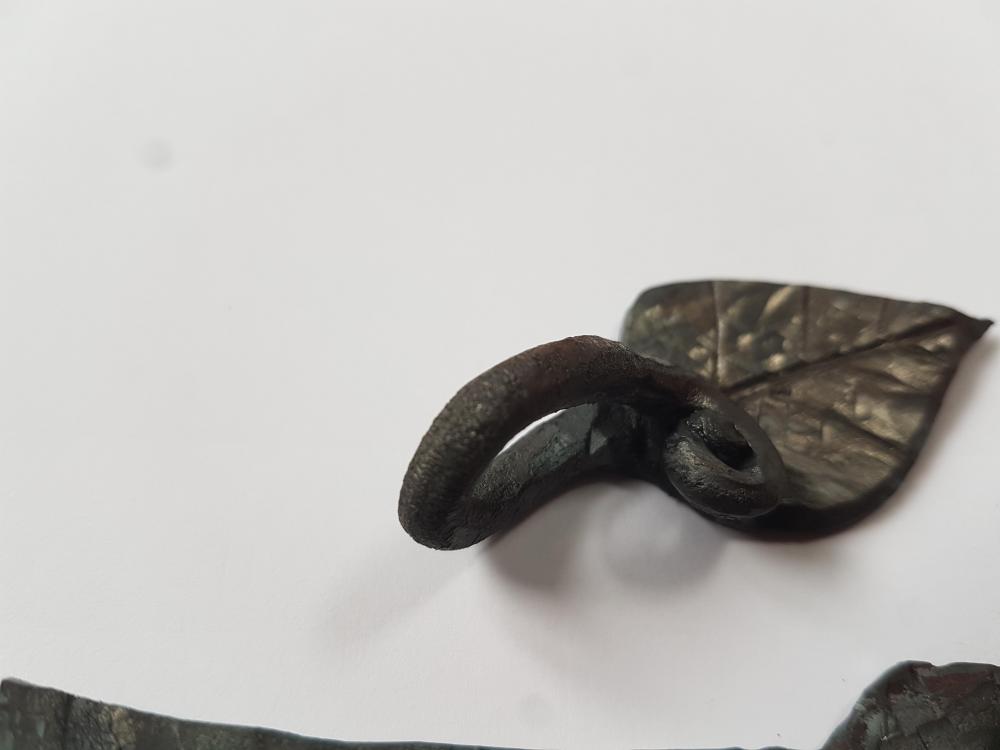

Well I've given it a good warm up and these are the first three things I have every forged, Bent a nail....then a bad leaf....then a better leaf.

-

What is it that you are descriving as the tertiary flame....what part of the flame am i looking for?

-

I've gone for a longer heat at around 5 psi and it was a steady flame. Are there any views/opinions on the video below? It shows me covering and uncovering the air inlet on the burner. Also worryingly when fully open my psi gauge shows a reading of over 40psi !!...that seems high as my regulator is supposed to be a 0.5 to 2 bar 20180919_114615.mp4 20180919_114615.mp4

-

Haven't done a long heat yet...still putting it together and haven't found it spot yet in the garage. Need to think where the forge, anvil and vice will go. Going to have to rearrange the workbench location probably too