Travo

Members-

Posts

25 -

Joined

-

Last visited

Profile Information

-

Gender

Male

-

Location

Vine Grove KY

-

Interests

Fly fishing and trying to forge

-

I am pleased with it. After it warms up it will hold 2200 at 7 psi. I only held it for about 10 minutes, but it worked great. It may start to drop off if I would have left it for longer, but like I said I am pleased with it. I was thinking of trying to extend the tee on the top of the burner. Figure it could not hurt to try. I am going to get 2 one inch close nipples and 2 one inch to 1 1/4 or 1 1/2 bell reducers and add a length of pipe to get the burner away from the heat. Say 8 inches. Have you tried this frosty? I will let you know If it helps any on mine.

-

Well it is finally up and running. No cracks in the Kast-O-lite and the metrikote is applied. Made it to 2200 f according to the K thermocouple I have in the exhaust port.

-

I may have to order some. The bricks I have are rated for 2400 and are now coated with metrikote. They should reflect good enough until I get some. I am ready to fire tomorrow afternoon to "dry out" the Kast-O-lite after it has cured. Then all that is left is the metrikote and tuning the burner.

-

I am trying to source some of the bricks you speak of locally. I may have someone I can purchase them from, but I will not know for another week or so. I will paint the ones I have with metrikote for now. If all else fails I can order some. Would casting one out of Kast-O-lite work?

-

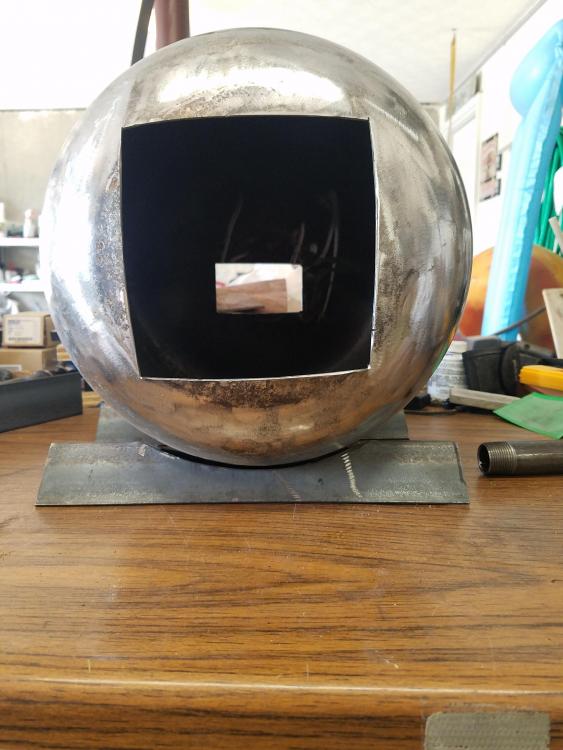

Here is pic wit the fire brick setup. I believe it will work pretty good. After the Kast-O-lite was put on I am wondering if I will need one on the back. It is a lot smaller now

-

Thanks mikey. I did have the bricks over the opening but removed them to try and get a picture of the swirl. I am putting castolite in it now. As soon as it sets up some I will finish and let set until tomorrow. Here is a picture of the inside so far.

-

So I received my new regulator today. Hooked it up and fired the forge to finish the rigidizer. Funny thing, this one puts out a lot more propane and in return you get a lot more heat. Who would have guessed... but the inside the forge started to melt my isowool. It is not bad and I think it will be ok after I put the castolite over it. Thoughts? Here are some remaining pictures of the build. The flame has a nice swirl to it. Hard to see in the photos.

-

Thanks for the kind words. I did run into a small issue. The concrete floor I sat the forge on to tack the feet was out of level. The forge rocks a little when on a flat table. Nothing a few shims cannot fix though. For the floor I did not have any way to split a fire brick. I just poured it with some lower temp refractory I had. I think it is good to 2300. I will cast over it with the castolite then paint with metrikote. Hope to finish the casting of the floor and cutting the burner port tomorrow. Then all that will be left for Sunday is to cast the sides and top. We will see how much I can get done tomorrow. Have a feeling I will be sore. I did change the back opening to 3x4. It is able to be covered with a fire brick easily though. The shelves work great on each end. I ended up welding the front shelf about 1/4 inch low as recommended. I believe it will help.

-

Well here are the pics of the build for today. Here are the rest. Right now it is about 380 cu in. I think I am going to put another small strip of insulation on the bottom before I put the refractory in it. This should bring it to about 350 and one burner should work.

-

Thanks Frosty. I only had the burner running for a couple of minutes total. I was curious as to how the different length mig tips would alter the output. I am in the process now building the forge. Thanks to Wayne I have my Cast-O-Lite and metrikote to finish it. I hope to be able to finish by Sunday. We will see how the shoulder holds up. The flare is made from stainless. Hopefully it holds up well. If not I will try other materials. Possibly B16 or Inconel 625.

-

-

Here is a short video after it has been running for a while. This is with a 0 to 10 lb regulator full open. 20180719_191936.mp4

-

Almost looks like a limb cutter. Just a guess. Interesting though.

-

The first picture was just after I built it. I believe the flame is looking better now (at least I think it is). At least outside the forge. This is at a very low pressure.Saturday. 0 to 10 lb regulator turned way down. I know everyone is worried, but I will not be running off of a 10 lb regulator. My 0 to 30 lb should be here saturday.

-

Well here is what I am calling the final design. I did move the back vent door and vent platform down even with where the floor will be. it is also even with the front of the forge. Feel free to use this drawing at your leisure. Final propane tank forge Drawing v1.pdf