-

Posts

44 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by olydemon

-

-

Completed a gift for my oldest son. He wanted a hanger from Amazon for his headphones. Why buy when I can make. I had started this project a few weeks ago (had to let my arm heal as you will see why...)

The starting stock was 1.25" 4140 round bar about 7.5" long. I drew this out by hand to a point about 14" long, leaving the original stock size at base. Process photos in the link show drawing it out and some sucker welding pics. Once the taper was finished, I welded the beads on and then let my arm rest for a week.... haha... actually this was last Sunday and I generally only forge on the weekends. Yesterday I finished the suckers, and then put a curve to it as much as I could. The 4140 is really tough to bend after its about .75" diameter, but It worked well for the hanger hook. I also forged out the base from some 3/16 x 4 square giving it a star shape with some texture. I didn't want to have exposed weld bead at the base, so I drilled a couple holes in the back to weld the 2 pieces together. Worked out well, and I think he will be stoked.

The Imgur album for the rest of the photos.. https://imgur.com/a/MWfRrRG

-

On 11/19/2018 at 6:02 AM, ausfire said:

Great ideas. I really like the twisted spanner. So was the business end a ring, or was the loop formed from the shaft of the spanner? It doesn't look thick enough to provide the mass, so I'm thinking it must have been a ring/open end spanner.

And that's how I test mine, too. No need to open them … unless you're thirsty.

The other end was the box end. I was worried the teeth would make it crack when drawing out the ring.

On 11/19/2018 at 9:07 AM, tkunkel said:Nice variety of openers. I like the curved handles and the chisel work.

Thank you! I'm hoping my wife can sell them at her craft table coming up for the holidays. I've given her pendants and leaved to sell with little luck. I think I need something practical to sell, hopefully to the bored husbands dragged out to craft bazaars.

-

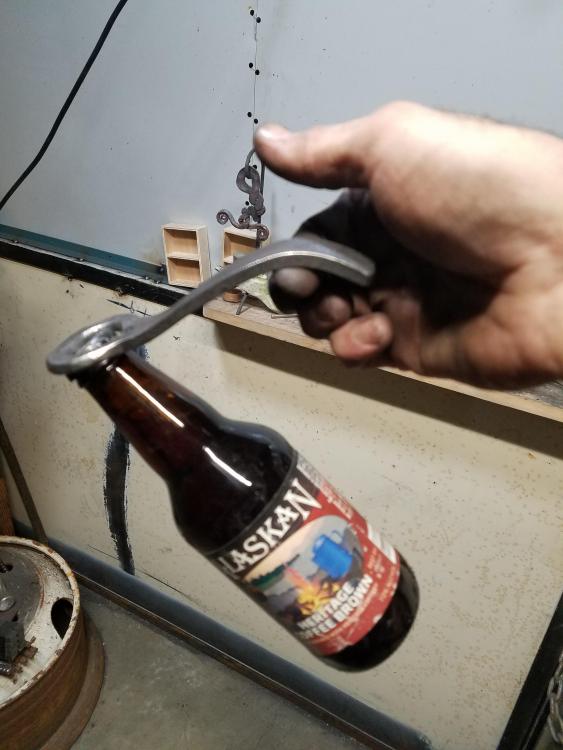

Spent some time this weekend making openers... I feel like I'm finally getting better at even(ish) loops and cap hooks. Each opener I make gets tested by holding a full bottle by the cap.

L to R-

Random pattern from 3/16 x 3/4 scrap.

5/8 wrench with a twist.

Old thick file.

Random beach salvaged bolt from old piers, possibly wrought iron (according to the person who gifted the material).

-

HAHA, didnt even think of that.... BTW. see you are in Oly too!

-

Thanks! They are fun to make.

-

Thanks.

The jig is just for holding the stock so I can punch the suckers by hand. Works well. I adapted the simple angle iron piece I saw a fellow Instagram contact had posted. My work has V blocks for holding round stock for measurments that have a similar bolt hold down, so I just combined the ideas.

-

I use wire wheel brushes on hex posts (like for a drill motor) in my dinky craftsman drill press. Get them at lowes/home depot. They aren't as aggressive as a wire wheel on a bench/angle grinder and I don't get any wire projectiles lodged in my clothing....

-

On 10/20/2018 at 4:45 PM, Frosty said:

Only rank beginner machinists tend to break or bend the things.

Frosty The Lucky.

Or Rank beginner operators who hand edit code because they didn't want to go get a program update... This was the result of a tool # changing on the controller and a repost from my program called up the wrong tool and proceeding to rapid into a hole that was suppose to be there.... This is a seco flat bottom insertable drill that seems cast...

-

Worked up a new tentacle opener this weekend. The hooks on the end are a result of a failed round punch in too thin of material. I started over with a slitter that left me with more material but I decided to leave the failed nubs as a part of the look.

Also pictured in the first shot are some Talon claws I like to make out of all the short round cuts you end up having sitting in the scrap bin...

Here is another opener I gifted to a good friend. I did a non traditional end with a little tentacle wrap. This one was a ton of fun to make. First time using my sucker punching jig pictured. My test of function is always hooking a bottle and balancing it in the air. If it works I don't get a broken bottle and beer on my floor. So far none have failed.

-

Been cool seeing all the openers... Here are a few more I've made. Going through my phone (my camera) I realize I haven't made an opener in quite a while... may need to remedy that... It's finally cooling down here so maybe worth firing up the forge this weekend.

Made from a chunk of 4140 shown to the left.

Here are a couple made from some cool rebar that was in my shop when we bought the house in 2002.

Some twisted variations...

Some I have made from files. My first is still my favorite. (the shorter one in the middle of the group photo)

And some weirder ones....

-

8 minutes ago, 4elements said:

There are a lot of us close to you. I'm in Granite Falls, WA. There are at least a couple of other smiths I know of in Olympia. Are you acquainted with the North West Blacksmith Association?

I am familiar with the NWBA, Lurk on the website all the time, Haven't joined yet. I always seem to be busy when there are events happening. One of these days I will...

-

1 minute ago, windancer said:

I like 'em both

Dave

Thank you! Also see you are not far from me. Hope you are handling the heat... I'm certainly not...

-

Thought I would update this original post rather than start a new one. I forged some more of the copper bar into a few incense holders and a skull. I also made the original snake thing into a door knocker. here are some images linked from Imgur..

Door knocker:

Forged a piece of random steel to the backing of he door knicker. I split the top end by hand, the other end I sorta cheated with the bandsaw. It was a really hot day and I wanted to just get it over with. I hid the cut seam ends with the curve of the snake.

The copper clasp is just 1/4 tube smashed flat. I used some really old copper rivets I got from when my grandfather passed away around 1999, was really cool finally finding a use for them.

Copper skull... I make these all the time from Mild steel... first time trying in copper....

Feather incense holder... I managed to melt the tip of something I was drawing out so Instead of a double ended curl (like my last piece to post) I ended up making it a feather and curling the end to hold the incense.

Here I use about 8" of the 1/2 square bar to draw out a viking ship incense holder. This is what I was trying to make when I did the feather. This came out really cool....

raw stock:

In process re-heating...

The finished part in various views:

some other images here that I didnt post... https://imgur.com/a/UpuhwZi

-

Thanks all! Eventually it would be fun to try something in silver. I do have a brass hex bar, but at 1" diameter I'm not sure I'm ready for that....

-

Having seen many posts on Instagram of copper forging, I decided to order a bar of copper from Amazon. I ended up with 60" of 1/2" square for only $26 shipped. Tonight I forged it since the weather wasn't too hot out... I started by cutting off 7 1/2" of the bar. The object I made is the Ouroboros, or the snake eating its own tail. It ended up 17 1/2" long after drawing out. I worked it hot when doing the taper. The textures on the 4 sides I just did with a chisel when it was going from dull red to black hot. It was really fun and I cant wait to use up the rest of the bar.

-

Greetings... Long time Lurker... Finally made an account last night to post some bottle openers. I've been smithing about a year now. I spent a lot of time early on making tools and tongs (Kens Custom for now). Now I make lots of skull and troll cross pendants, runes, bottle openers, and other weird things. I always have people asking when I am going to make knives since they all think we all are just waiting to be on FIF. I've made a few blades, and a few forge welded hawks.. In time I want to make more of this stuff, but for now I enjoy more artistic things. Most of what I make I end up giving away, but do have a few people who I sell stuff to on a regular basis. Some of my work will also be at a Oddity and Curiosity expo in Chicago in a few weeks with a friend who needed something smaller to sell on his tables... His art is quite expensive I guess..

I look forward to spending more time picking through threads here... I also lurk on Reddit but don't post too often. My main outlet these days is my Instagram account here: https://www.instagram.com/olydemon/

-

1 hour ago, tkunkel said:

Olydemon, Nice work with your Damascus opener! Skulls and tentacle are pretty neat also. Could you explain how you did the texturing on the tentacle? Thanks for sharing. Tom

Thank you!

The tentacles I learned from a smith named Hanna Gutke through a YouTube video. . I'll post the video as here as her tutorial is pretty good and funny. Basic steps: Make taper, Mig weld dots, Punch dot centers.

https://www.youtube.com/watch?v=giS_d4nu9VM

-

Finally joined up to share some bottle openers I have made. I've been a long time lurker usually ending up here looking for info on forges and anvils.

The damascus one was my first attempt with making my own layered stock. I used band saw blades and strapping. The texture didn't end up staying so I polished it again as seen in the shiny image and later heat tempered it to a rainbow pattern. I didn't have a great image of that, but could dig it up later.

The weird bearded skull/tentacle one was made as a response to a challenge from a friend to make a "Skull with a tentacle". I ended up giving it to him as a gift.

The last one was made out of 303SS and it cracked on me so I went with it and made an opener I think looks sorta like a crab claw. I have access to 1" round bar in 303ss, but It was such a pain to forge i may just let the stuff go to the recycler.

What did you do in the shop today?

in Blacksmithing, General Discussion

Posted

Thanks!

Your suggestion is actually exactly what I am thinking about for a multi tentacle piece out of smaller diameter material. I didn't think about doing it for this one, but looking back, maybe I should modify it.....

A cheap buz box from horrible freight or used off craigslist would be all you need for this... Maybe even Flux core.

Thanks too! It was a ton of work for sure. I said I wouldn't do it again, but I probably will...

I also like Vaughn's idea too. I'll update if I revise this one...

That is some seriously nice work!