-

Posts

14 -

Joined

-

Last visited

Profile Information

-

Gender

Male

-

Location

Ball Ground, GA

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

Thanks!

-

Could I get some opinions on this please? I was looking for something more substantial than my 66 lb soderfors and this is really close. Do you think it would clean up will or what should I look for if I go see it? Commercial link removed per TOS.

-

-

Been looking at info about dressing hammers, now that I know that's a thing. I need to update my description to be more clear, the edges are a little rounded, which seems to be a good thing, but that wasn't what I was actually trying to get at. One side specifically, the top of the face is longer than the bottom so the face slants a little. It is a "round" slant but it looks like someone had been pounding on the bottom of the face mostly instead of hitting flat. I'm thinking that needs to be brought back to flat and then dress the whole thing to make sure I dont have sharp edges. I was reading about the "wood test" to see if you are hitting flat but I think hitting flat with that side would leave a 12 o'clock indention, if I am making sense here.

-

Went looking around at a couple flea markets today and spent a total of $3 for a few odds and ends. The thing I was most excited about was a hammer head I found hiding behind a barrel of shovels. It was rusted up and cost me $1. Brought it home, took a wire brush to it, and treated it with linseed oil. I would have liked to make my own handle but my shop is in the beginning stages and I dont have the tools yet so i ordered one. My question is; the hammer faces are just a little rounded from use. I was thinking of taking a belt sander to it to flatten them out but wanted to see if that was a good idea or not. I dont want to mess anything up. Any tips? Oh, it weighs in a 2 lbs 7 3/4 oz.

-

One more newbie question. I think every other home made forge design I have seen has fire brick and/or some kind of refractory in it. From my reading I get that the fire would stay in the rotor you used since that's where the air is being fed in at... but it still seems like that rotor would get really hot. What's the determining factor on if a refractory material is needed in forge construction?

-

Question Glenn, I read in a post on here somewhere about a bucket of water under the supercharged 55. Could you tell me a little about that? Is the bottom of the blast pipe just submerge to seal it for air and catch anything that falls from the forge?

-

Thanks Glenn, Thats what I was looking for. I am still trying to figure out what I am going to do, I have a few ideas.

-

I have been looking for almost an hour for blueprints for the 55 Forge and its variations. I have looked through the blueprints section and did a google search for this site. Ever link I ran across doesn't work. I just happen to have a 55 Gallon drum laying around to use but I was looking for a little more detail on how to construct it than I found in the original post. I want to build a bottom blast but I'm curious about the Supercharged as I haven't been able to find anything specific about that one.

-

Good to know, thanks Thomas!

-

Iron Dwarf, I did the tap test you mentioned. I found one spot that sounded a little different. On the picture above its the spot about an inch below the hardie hole. I took a video so anyone who would like to hear it can: https://youtu.be/EydfTRddpt4 I read on the forum someone had a "rule" of 1 pound of hammer for every 20 pounds of anvil weight. by that I could use up to a 3 pound hammer on this. Could someone give me an idea of what kinds of work an anvil of this size/weight would be good for? Thanks for all the replies so far folks!

-

Thanks Thomas! Looking forward to learning about it. What about the damaged part on the top? Is that going to cause issues? Should I just not hammer anything on it or not worry about it at all? Location and Pic added.

-

BenM changed their profile photo

-

here's the pics so you don't have to download, still figuring this out... Also, I have read the "read this first" post, and have read to wire brush it but not mill it or anything like that. Any other care tips would be appreciated.

-

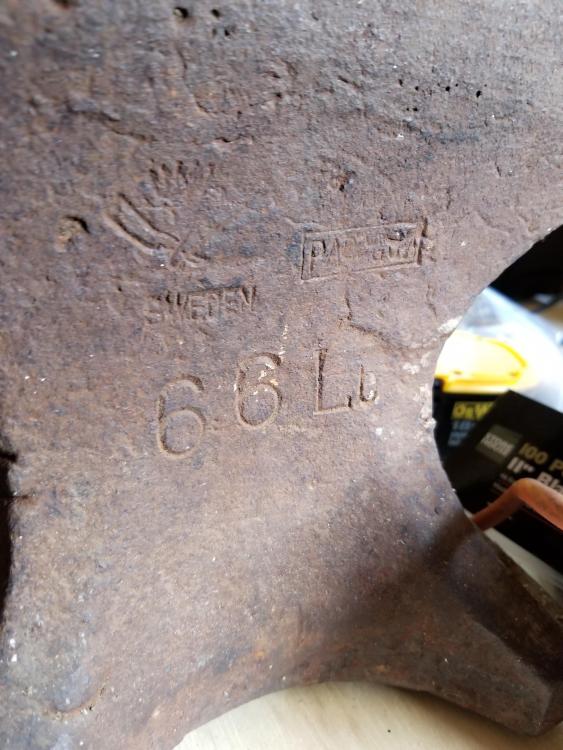

Hello all, Been lurking here for a week or so, Just getting into blacksmithing. My great grandfather was a blacksmith and I have his anvil and vise. I know nothing about anything and wanted to see if there was any information I could get regarding these items. The anvil has "66 Lbs" and "Sweden" stamped on the side. Seems to have a little damage on the top. It has been used as decoration or been in storage for my entire life so I don't know anything specific about it. Planning to use it whenever I actually get started since its what I have. Really just trying to figure out what I'm working with here. Thanks in advance! DL links remove