-

Posts

4,053 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by George N. M.

-

-

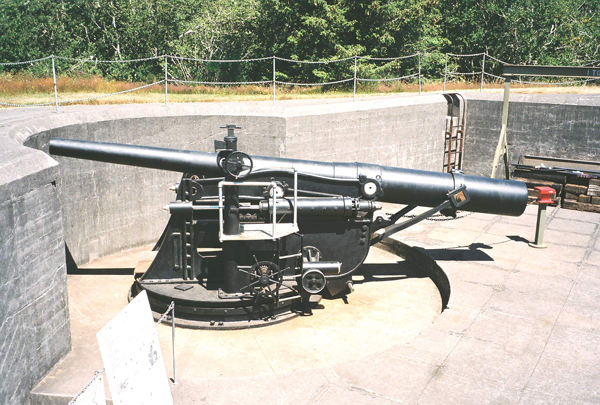

Speaking of historic reproduction artillery here is a reproduction 6" gun on a disappearing carriage at Ft. Stevens, OR aaaaa0mouth of the Columbia River). These were coast defense weapons which were active from the 1890s to WW2. They were loaded in the retracted position, as shown, and then when ready for firing a big counter weight in a well was tripped and the barrel would rise over the parapet for firing. The recoil would bring it back into loading position.

On this carriage (15 degrees maximum elevation) this gun could shoot a shell weighing about 100 pounds up to 17,600 yards (10 miles).

I've worked with a surviving one in San Francisco and it is a LOT of work to turn the big crank to raise the lead counter weight. But it is very cool to trip it and see the gun rise into the firing position.

-

Probably a very good score. Snowplow blades probably are a more complex alloy than plain 1090 because of the need for abrasion resistance. This may make it somewhat harder to work. My suggestion is to cut a 1/4" or so off the end and experiment with how it works and how it heat treats (and keep notes). Try different quenching mediums and break pieces off so that you can examine the grain structure. If it works out you have gotten a piece of high C steel that you will be using for years at less than scrap value.

"By hammer and hand all arts do stand."

-

in a situation like this where you are making things for a specific audience at a specific location you have to be aware that you may, and probably will, saturate the market pretty quickly. We make durable goods and once a person has bought an X they are unlikely to buy a second one. I have done events where I did great the 1st year, OK the 2d year, and barely covered costs the 3d year because the same people were coming back every year and they had already bought the things they wanted from my offerings.

So, you either have to keep coming up with new items to attract subsequent sales or move your stuff around to different outlets where a new group of customers will be exposed to your wares.

"By hammer and hand all arts do stand."

-

This is yet another time that I miss Thomas' input since he had a medieval falconette which IIRC was about golf ball caliber.

G

-

Also, you will often see folk ramming with one hand. You really don't need the force of both hands to firmly place the projectile against the powder charge.

BTW, there are a number of internet sites about how to build a cannonball mortar (no links intentionally). Apparently there is a specific size of compressed gas tank that is used in welding shops that is just the right size and is, of course, good quality steel and stessed for the pressure involved.

G

-

The touch hole is sealed with a thumb to keep air from blowing out of it during ramming to avoid fanning any sparks in the bore. There is a thing called a "thumb stall" which is a leather pad to protect the thumb from the heat of the gun tube.

There is also a safety rammer which has a cone shaped head so that it puches the hands out of the way incase there is an accidental discharge and the rammer staff comes flying out of the barrel. There are re enactment groups that require the person ramming to wear heavy welders gloves while ramming as a safety thing.

There is a big Scottish-Irish festival in Estes Park, CO that I used to demo at (until they started charging crazy booth fees). There was always a group there with period weapons including a bowling ball mortar. They made it out of large piece of pipe with a smaller, heavier, detachable chamber welded to the base. They would fill the chamber with a few ounces of black powder (maybe 1/2 cup) and screw it to the breech where a bowling ball had been loaded. When fired it would launch the bowling ball about 300 yards into Lake Estes. They once hit a rock and the bowling ball bounced about 50' into the air and about 100 yards further. Luckily it landed in the water. If it had bounced in another direction it could have hit folk on the shore. Moral of the story: sometimes you do hit your aiming point and you need to consider what will happen if you do. IIRC after that incident they used an inflatable dragon anchored away from the rock as an aiming point.

The lake is a reservoir and is drawn down in the winter and they'd go out when the water was down and collect the bowling balls for future use.

I don't think that it would be too difficult to constuct a bowling ball mortar if you were a decent welder. It would be safer than a long gun because the powder charges are much smaller and the pressures are much lower. You'd just have to find the right diameter pipe (bowling balls are 8.59" in diameter) and a breech piece (IIRC it looked like the hemispherical end of a pressure vessel welded to the pipe/barrel.

GNM

One of my pet peeves in historical movies is when the cannons don't recoil. Oddly, you will see cannons recoiling much more often in naval movies, e.g. Master and Commander, than you do in movies set on land. As can be seen in the video muzzle loading cannon recoild back 5-6' pretty violently and you do NOT want to be in the way.

G

-

Being an old artilleryman this is something I have always wanted to get into but never have for various reasons. If you haven't watched this Youtube video it will show how full size Civil War cannon recoil when fired with full charges and projectiles:

-

$25 is what I paid for my first forge, a cast iron pan Lancaster rivet/farm forge, in 1978. $25 was cheap then, in 2024 is amounts to Grand Theft Forge. Great score.

"By hammer and hand all arts do stand."

-

If you are in an area that gets lots of miller moths you can put a light bulb a few inches above a pie pan of soapy water the moths will circle the light, hit the water, and drown pretty instantly. It works best at night when there are no other lights in view. You may have to stir up the millers resting on the cieling and walls with a broom or a towel to get them flying.

When they are on the ceiling and walls and are kind of torpid at night you can use the wand of a vacuum cleaner to suck them up.

Millers are harmless but annoying.

GNM

-

A couple of thoughts:

1. Might they be shotguns (aka "fowlers") rather than muskets? How thickk are the barrel walls at the muzzle? If they are "thick" they are probably muskets. If "thin" they are fowlers. Also, there do not appear to be any rear sights. Are there any front sights? I can't tell from your previous pics. If no sights, front or rear, that is evidence that they are not muskets. Measure the bore and see if they are the caliber of common shotgun gauges (10 gauge = .775 cal., 12 gauge = .729, 16 gauge = .663, 20 gauge = .615, etc.)

2. Is there any writing on the lock plates? It kind of looks like in the photos but I can't tell for sure.

3. In the first photo it looks like there is sort of a ridge above your middle finger extending from where the nipple would go in line with the hammer. If so, it appears to me that it may have been made of percussion ignition rather than being a flintlock conversion.

4. I don't see any empty screw holes in the lock plate in front of the locks which would have secured the frizzen (the striking plate that the flint hits) spring for a flintlock. so, that is evidence that the locks were originally built for percussion ignition.

5. the fore ends of the stocks look nice enough that I think they look more like original fowlers than being cut down from military muskets or hunting rifles.

Folk who know more about black powder weapons (I'm looking at you, Irondragon) may have more to contribute.

My sense, for what it is worth is that they are shotguns/fowlers dating from about 1830-1870. If they turn out to be 12 gauge caliber I won't be surprised. I wouldn't try shooting them but i would try to replace the nipple on the one which just has a hole in the side of the barrel.

If you hang them on your wall you can forge some fancy wall hooks for them.

Still, very nice score.

GNM

-

Welcome back Slag. I/we have missed you.

George

-

I have seen a number of large steam engines run on compressed air. I have been told that the problem is that seals and packing will dry out with compressed air where they would not with "wet" steam.

One of my favorite memories of a steam traction engine was when we were at a Sweet Corn Festival and Niagara-on-the-Lake, ON. There was a large traction engine on the main street which had a steam line connected to a 55 gallon drum full of sweet corn. The worlds larges, most complicated, and expensive corn steamer.

GNM

-

But, with percussion locks you are dependent on one more manufactured item, percussion caps. That is one of the main reasons that trade guns for the Native American trade in both the US and Canada stayed with flintlocks for long after percussion ignition was common. Also, there was the idea of providing possible enemies with weapons that were not as good as what you had.

GNM

-

Ed, it is a lovely hachet but I will have to be a bit of a nay sayer. Years ago I was on a camping trip with friends and someone had a commercially made one similar to yours (not as nice). I recall trying it and not being impressed because the weight was not in the head which changed the balance from what I was used to and the head area didn't have enough mass. It didn't "bite" as well as one with a heavier head and lighter handle. Maybe I was using it for something too heavy for it like chopping a limb or something. I can see it as a splitter for straight grained wood or going through a pelvis when field dressing a game animal.

Still, a very attractive job.

GNM

-

Definite pass. Good move not to get caught in a bidding frenzy/competition.

"By hammer and hand all arts do stand."

-

Here is a link to a report of a recent Bronze Age find in Poland which includes bronze sickle blades. I imagine that using a bronze sickle would involve a LOT of sharpening but it must have been worth it compared to the alternative. I recall seeing Neolithic sickles with flint blades set along a curved wooden handle.

-

Welcome aboard from 7500' in SE Wyoming. Glad to have you.

I'm afraid that the link did not open for me.

In my experience swinging a large tool like a sledge or a pick is more about controlling its direction and point of impact rather than brute strength. You let the weight of the tool and gravity do its work and you just guide it to where you want it to go. That said, exerting that control is a very subtle skill that does not come easily.

"By hammer and hand all arts do stand."

-

I have heard that heating to forge welding temps will not "heal" micro fractures in a spring but I do not have any first hand experience. I yield to those with more specific knowledge.

GNM

-

Back in the late '60s and early '70s I had a friend who had an elderly great aunt who lived in the back of beyond, West Virginia and cut her tall grass with a scythe. She complained that you couldn't get goof, American made, scythe blades any more and she had to buy imported Austrian (IIRC) made blades.

There is a great hardware store (Arp Hardware) in Boulder, CO which still stocks scythes along with all the other shovels, rakes, etc.. If you are ever in Colorado Arp Hardware is worth a trip to Boulder. There is very little that a person needs in life other than food and clothing that they don't stock.

GNM

-

There was a similar incident in Laramie in IIRC the 1890s. A lady whose mother was expecting at the time was always told that she had been born when there was an elephant in the back yard. Every word true.

GNM

-

I have seen miners' picks with a similar curve. The idea is that they are easier to swing in the confined spaces in an underground mine. The idea may have been that a curved head is more ergonomic and follows the arc of a swing of the arm.

Others may have more details. There are old Atha Tool catalogs on line that you could go through. Here is a link to the 1912 catalog:

https://ia802309.us.archive.org/22/items/atha-tool-co-catalogue-1912/Atha Tool Co Catalogue 1912.PDF

"By hammer and hand all arts do stand."

-

Yeah, the buggy eyes are reminiscent of Peter Lorre. Also, Marty Feldman. Why the last one?

G

-

Old car springs, either leaf or coil, are a good source of fairly high carbon steel but they have two possible drawbacks. One, they may have thousands of little microfractures from long use of many, many cycles of being compressed and relaxed. These can result in failure points when forged into a blade. The newer the spring the better. A good source are places that do custom suspensions where they take off and discard the brand new factory springs and install some sort of custom kit, e.g. lifts. Second, some newer springs are odd alloys which are harder to work in a home shop. Always, experiment with "coupons" to see how a particular spring will work, harden, and temper. Once you have hardened it you can snap it in two and look at the crystal structure on the line of the break. The smaller crystals the better.

Do you have some particular reason for wanting to make a sickle? Maybe hanging it on a wall crossed with a hammer to symbolize agriculture and industry? ;-)

"By hammer and hand all arts do stand."

-

OK, a couple things: First, rebar is probably not the optimum steel to use for this because it varies in compostion pretty fast along the length of the bar. It may be fairly high carbon at one point and a few inches away it is very different. Frankly, given the amount of work and time you are going to put into this you are risking losing a lot of effort because the sickle may fail at an unexpected spot during fabrication or in use. You may have a nice hard edge at one spot and it will bend like a noodle a few inches away. I think you would be better advised to use something of more consistent content like a spring if you are using scrap steel. Experiment with a sample (a "coupon") to see what quenching medium and tempering process works best. You are more likely to come out with a good, usable tool.

Second, a sickle is nothing more or less than a specialized knife for cutting grain stalks. Grain stems are pretty dulling to a blade because of the silica spicules in the stem. So, I'd think that you would need a fairly hard edge so that you don't have to resharpen as often. The blade is fairly long and thin. So, I think you'd need it to be somewhat springy even though it may not get much in the way lateral forces in use. I'd try for a differential temper with the edge being dark yellow or bronze and the back of the blade a blue.

I don't think work hardening is going to be much of an issue one way or another. Yes, you could get some work hardening on the edge by hammering but IMO that would be of minimal effect compared to proper hardening and tempering.

And, yes, if you do have something with a resaonable amount of carbon, harden it, and then "bonk" it you will likely snap it off. That is why you temper hardened steel, so that it is more bonk proof.

If you don't heat treat it at all you can sharpen it but it will dull quickly in use. Basically, you have made a wall hanger, an object that looks like a sickle but is not very good at doing what a sickle is supposed to do. Yes, prior to easy availibility of steel scickles were often made of wrought iron but I suspect that in use the scickle wielder spent almost as much time resharpening as cutting.

Finally, it is kind of tough to forge a curved blade with the edge on the inside because as you thin the edge the metal wants to curve away from the edge because while the metal is being made thinner the excess has to go somewhere which is spreading out. Yes, it can be done but it takes good hammer control and a feel for how to counteract the tendency to curve away from the edge. You may need to start with the thicker piece of metal than you would for a straight blade because in controlling the inside curve you may need more metal to avoid over thinning the back of the blade. I suggest forging a practice one in mild steel or a piece of rebar and then, once you feel comfortable with the technique, make your final version in good, high carbon steel and then do your heat treating. And, remember, if something is too thick you can always grind or file the excess metal away. There is an old expression of "If a good blade you would win, forge thick and grind thin."

"By hammer and hand all arts do stand."

Catchingrabbits with a forked stick?

in Everything Else

Posted

The tale is an American version of the "Musicians of Bremen", a German folk tale collected and published by the Brothers Grimm is 1819. Versions go back to the Middle Ages. Here is a link to the Wiki article: https://en.wikipedia.org/wiki/Town_Musicians_of_Bremen

GNM