-

Posts

90 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Nick Owen

-

I made a thing! Copper Elf/Iron Dwarf

Nick Owen replied to Nick Owen's topic in Blacksmithing, General Discussion

Yeah I figured that after I had poured it in It has made a nice little bowl for it to move towards, if it causes problems I'll just shovel it out. Worked a treat yesterday though. Yesterday I was just bumbling about with very little confidence to know what to do/try even after watching videos but I feel pretty well equipped to combine skills and try a host of things. Lots of things that I need to make to make my own life easier and Iron Dwarf was on hand to fill my boot with practice steel at a great price to do it with John hit the nail on the head with coaching as well. He allowed me to set my own standard and had the patience of a saint as I cackhanded some parts. Low pressure. Lots of fun and skill. It was 28 C when I left at about 5 (according to my oh so reliable car thermometer). God knows what it was by the forge but it was nowhere near as bad as I thought it would be. I probably wouldn't have been much more comfortable with the heat in my own house. Busy minds have less time to gripe. -

Hi, Thanks forum people for the advice over the last few days/weeks to help me get set up! I just got back from Glendon Forge and had a great day shaping my first steel into shapes (intentionally this time!). John (Copper Elf) and Dave have helped me out loads. John was patient with my rather haphazard and dainty hammer swing and took me through upsetting, isolations, twists, drawing out, hot cuts, hot sets and so on. I wish I had taken a few photos of the process but I'll post up some photos of the finished articles. I think most importantly I've come away with the confidence and skills to redo the projects to a better standard.. you'll see the obvious mistakes below Great guidance, a really fun day and worth every penny I started off with an S hook and got up to a keyring, bottle opener, toasting fork and a fire steel. Not the most beautiful you will have ever seen but I know I can and will now do better! Thanks to Dave (Iron Dwarf) as well, he has hooked me up with a great forge (that I got plenty of practice with today) that is super simple to use and worked tirelessly ( ) on his bank holiday Monday to also built me a solid anvil stand to perfectly fit my double bick . I really couldn't ask for better guidance and support so credit where it is due to John and Dave. I will be back! Excuse the mess in the background, my garden is part jungle, part construction yard as I'm remodelling the house right now! I think John will appreciate the reference after a good chat today.

-

Platform on the side of an anvil

Nick Owen replied to Nick Owen's topic in Anvils, Swage Blocks, and Mandrels

I set the forge up today and managed to get a really good heat out of it. I have however realised that my left arm is just not used to the kind of strength required to swing a heavy hammer. I can't move my left thumb any more.. :S Must use smaller hammer. Must ease into it -

Platform on the side of an anvil

Nick Owen replied to Nick Owen's topic in Anvils, Swage Blocks, and Mandrels

Well I'm unlikely to say no anvil stand is my true love though -

Platform on the side of an anvil

Nick Owen replied to Nick Owen's topic in Anvils, Swage Blocks, and Mandrels

Yes. My casual switching between imperial and metric doesn't go unnoticed. I'm a child of the metric generation but Hardy holes are always discussed in inches -

Platform on the side of an anvil

Nick Owen replied to Nick Owen's topic in Anvils, Swage Blocks, and Mandrels

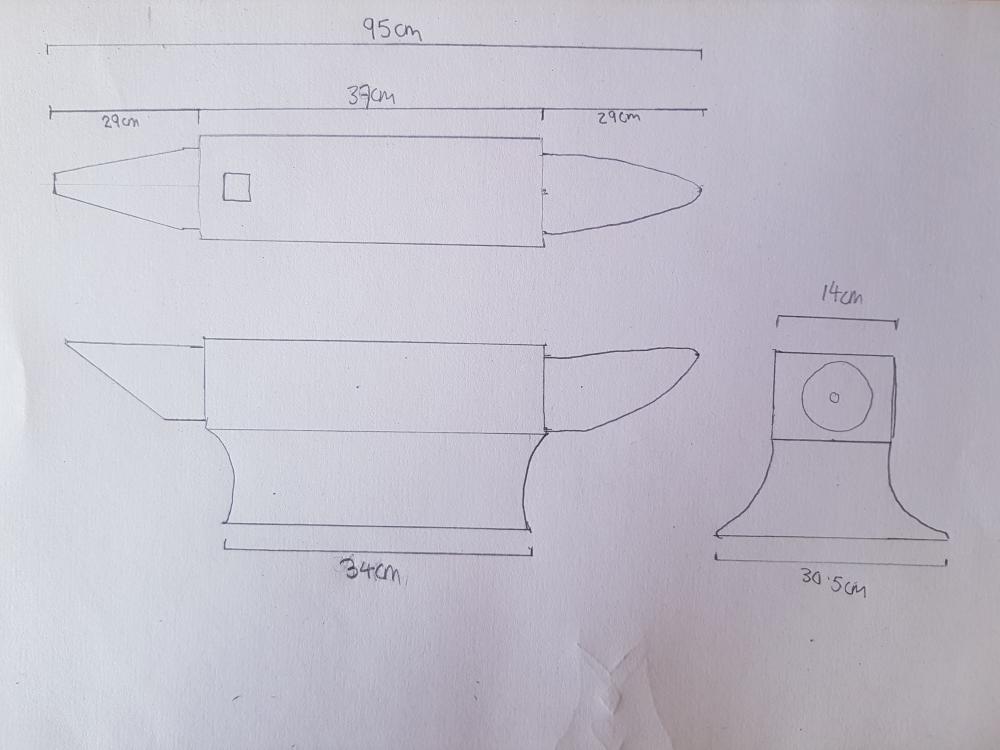

Derp. Missed those off of the sketch! The anvil is 32.5cm tall. The big Hardy hole is 1.25inch square, the small 0.75 inch. Is that the right measurements? -

Platform on the side of an anvil

Nick Owen replied to Nick Owen's topic in Anvils, Swage Blocks, and Mandrels

I'll be pulling all of the stops out to damp it out calking, magnets/chains and making sure it's securely down. I'm an end row house so my garden joins on to six others and I don't want mad neighbours -

Platform on the side of an anvil

Nick Owen replied to Nick Owen's topic in Anvils, Swage Blocks, and Mandrels

All in good time Drawings are not to scale, just rough outlines but hopefully these measurements should be useful? Excuse the mess in the photos, I'm completely redoing my kitchen so the outside is being used as storage and construction yard She's loud too... Think I might have to do the anvil work inside the extension on I'm going to drive my neighbours loopy -

Platform on the side of an anvil

Nick Owen replied to Nick Owen's topic in Anvils, Swage Blocks, and Mandrels

That would really be something if we could! I'm sat here scratching my head at the idea of it and I don't like the original 4x4 wood stack that I was going to go with.. For anyone in England looking for a great source of help, Iron Dwarf is your guy. Will post up photos and reviews of his solid fuel forge once I get it up and running My cup floweth over from the font of useful information I've already cracked from his head -

Platform on the side of an anvil

Nick Owen replied to Nick Owen's topic in Anvils, Swage Blocks, and Mandrels

I'm sure the company I rent my car from would understand Fair wear and tear damage that is.... -

Platform on the side of an anvil

Nick Owen replied to Nick Owen's topic in Anvils, Swage Blocks, and Mandrels

I don't think I have anything strong enough to take the weight and I don't want the weight to pivot on the lip of my boot. My weak little car will probably crack all the lining or worse :S EDIT - Nevermind... I got it out... turns out I'm strong enough, my neighbours are not.... -

Platform on the side of an anvil

Nick Owen replied to Nick Owen's topic in Anvils, Swage Blocks, and Mandrels

Yes. No hidden pun. Two guys lifted it into my boot for me and I had reasonable confidence that I could get it out with the help of a neighbour... unfortunately even the fittest of them can't shift it so it's just sat in my car waiting to put someone's back out This is one of the more ridiculous questions I've asked but I was wondering if anyone had any bright ideas to get it out? Back work clearly isn't my strong point or that of my nearest and dearest Got the black one, but it is now stuck in my boot and I have no idea at all as to how to get it out... -

Platform on the side of an anvil

Nick Owen replied to Nick Owen's topic in Anvils, Swage Blocks, and Mandrels

Will find out later today but pretty sure it will be the black one -

Platform on the side of an anvil

Nick Owen replied to Nick Owen's topic in Anvils, Swage Blocks, and Mandrels

Is there an easy way to get the wood to stick in all directions vertically? I don't really have resources to hand to build a metal brace at the moment. -

Platform on the side of an anvil

Nick Owen replied to Nick Owen's topic in Anvils, Swage Blocks, and Mandrels

Don't know but it was sure pretty! That one had a great ring and rebound too. Will take photos of it when I go to collect my one on Saturday... I assumed that the black one would be the one that was £399 but I'm guess that was actually meant for the 'extra large' one. Could probably talk them down to £300 on that one but there is just no way I would get it back to my house or carry it through my house to my yard! (I have no read entrance to my garden). I couldn't even lift one side of it without using both hands and a lot of heft. Can't wait. Metal, tongs, hammers, safety gear is on its way... should be picking the forge up from Iron Dwarf on Saturday morning and the anvil should be coming back with me on the way home as well... The only thing I need is to build an anvil stand which I might do by stacking, gluing and screwing 2x4s together. I don't think I'll be able to wait for that to be built though, I can imagine I'm going to do something stupid like try and forge at floor height on Saturday night. -

Platform on the side of an anvil

Nick Owen replied to Nick Owen's topic in Anvils, Swage Blocks, and Mandrels

She's appealing to me all the more. Managed to get it for £220 which is almost bang on $300. Not a bad price as eBay comparisons go around here. I have reserved both so will double check ring and rebound when I collect on Saturday. Might see if I can buy a ballbearing on quick delivery for the purpose -

Platform on the side of an anvil

Nick Owen replied to Nick Owen's topic in Anvils, Swage Blocks, and Mandrels

I like your reasoning I think I might just go with the black one because I like it better.... shhh I've had two black motorbikes, first was Black Bess and the second was Black Betty (bam ba lam) so anything black, shiny, likely to cause injury and cost more than I have money for appeals to me -

Platform on the side of an anvil

Nick Owen replied to Nick Owen's topic in Anvils, Swage Blocks, and Mandrels

I've just received a reply back from the place and I could have either for the same price. Any advice on which one to pick. If I recall the black one had a bit of a better ring to it but I can't be sure now. The black one does look in better condition and I guess the two horns are nice. I have asked for some extra photos of the black one as I can't recall if it has two hardy holes or one hardy and one pritchel hole. Obviously on photo inspection it's difficult to say but any advice would always be appreciated. -

Platform on the side of an anvil

Nick Owen replied to Nick Owen's topic in Anvils, Swage Blocks, and Mandrels

Interesting! That at least gives me some idea where to start, I had no idea what to name it when I was searching -

Hi, I'm looking at buying the anvil in the photo (not for the price listed on top...) and it has a little platform that sticks out of the side. Total noobie question what is it for/called? You can just about see it sticking out on the back right hand side. Apologies for awful photo but the guy at the rec yard was already looking at me funny because I bought my own hammer and kept tapping away at it and bouncing things off of it so I just rushed through photos For information purposes I think that the 'extra large' tag was actually meant for the beast behind that you can't see.

-

That's my thinking. Will hit the local scrap dealers and see how open they are to me poking my nose in and pulling out leaf/coils. I will have to watch some videos on how to remove them, I'm really not a car person If I spend a while just turning them into a stockpile of workable stock I will have something to practice against so I'm not hammering away money for other things

-

Some great ideas, thanks guys! There is a local metal working place that a work buddy used to work with so might pop in there but I think they mainly deal with gates/fences so probably only mild steel available. Garage sales aren't really much of a thing over here. We do have car boot sales but never really sure what to buy that would be good. I imagine that tools probably have some good steel in and they are often plentiful. Not likely that I'll be able to whip out an angle grinder and do a quick spark test in the local school field I guess I was just a little disappointed at the price of flat stock 1055/1095 for blades. £30 for 600mm seems pretty steep, especially if you're going to mess it up in the early stages

-

Evening ladies and gents, I was hoping that some of you might let me into your deepest secrets and let me know where you source your steel from? I've been back through some old forum posts but it seems a lot of the links are now dead or not as relevant as they once might have been. The 'high grade steel' ebay/website seems like easy access to 1055 and 1095 but was hoping someone might know cheaper sources? On a side note are there any great places to scrounge steel from as well? I'm guessing the scrap yard is a pretty honest bet but maybe there are some other good sources that I'm ignorant of?

-

One of your forges is my preferred choice right now. I just need to find a time to come over (it was me emailing you ) I think that just for the fact that you are happy to demo is a great selling point. Just can't wait to get set up!

-

Hunting them down is my top priority right now