-

Posts

80 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by Joël Mercier

-

-

Old stock new files from Nicholson if you can find them. Otherwise, Simonds USA or Nicholson Brazil are ok.

-

Over sanitizing brings other issues as well. Our immune system is weakening over the years. Of course, this isn't a good reason to risk food poisoning but let's just be reasonable...

-

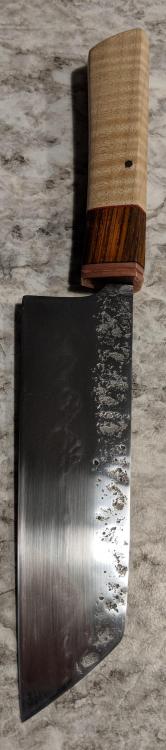

I had no problem with it until the "kitchen knife unsuitable for the kitchen" part. An obvious lack of tact IMO. Less suitable, maybe, but downright unsuitable is an opinion and not a fact.

-

Oh well, one would think someone would take the time to properly wash his 300$ kitchen knife. Anyways, this question was brought up during the knife design with the client which is also a friend of mine.

I hope we can now close the can of worms. No more unthoughtful opinion about a kitchen knife supposedly unsuitable for the kitchen on someone else's thread. Thanks

-

1 hour ago, SLAG said:

Check out Salmonella, E. coli, Campylobacter, Chlostridium tetani, etc. food poisoning.

Don't get me wrong it is a beautiful knife.

But it is NOT suitable for the kitchen.

Especially not a commercial kitchen.

It's going to have regular use in a kitchen, not a professional one that is. First, the textured part is quite high and most food won't touch or barely touch it. Second, this is not a butcher's knife in any way. Third, we often see texture in Japanese knives and nobody complains about it.

All in all its just about common sense...

-

I like pretty much everything about them, including the story. They look like real performers that are going to be used for generations.

-

In my book, if it cuts well, holds it's edge and doesn't chip, you have a good blade

. The rest is ergonomics and aesthetics.

. The rest is ergonomics and aesthetics.

-

end of story.

end of story.

-

That's a good question. I am following.

-

Thank you sfeile! And I am left handed too

. This was a commission for a friend's girlfriend. Both right handed of course.

. This was a commission for a friend's girlfriend. Both right handed of course.

-

3 hours ago, JHCC said:

Very nice, indeed. That might just be the inspiration I need to finish mine (that’s been sitting half-finished on the shelf for months).

This is the nicest compliment I've received about my work. Thank you very much sir!

And thanks Lou! Much appreciated.

-

Thank you DuEulear!

-

-

Fine work, and I agree on the slicer part. It seems scary sharp just by the look.

-

I'd just make a bucket that's harder to flip. A 6'' pipe welded to a 2'x2' steel plate is what I use.

-

Here's a small video of my tempering setup. I temporarily put the solid state relay out until I insulate the inner wall. I am very please of how this cheap PID completely leveled out the temperature. Notice the duty cycle light blinking, it has a self ajusting duty cycling.

-

This is nice on so many levels! Thanks for sharing!

-

We've got all kinds of answers

. It's mostly personal preference and technique. IMHO a 8"gyuto style is the best all around and a 6-7" santoku is best for veggies(if you use the right technique).

23 hours ago, BIGGUNDOCTOR said:

. It's mostly personal preference and technique. IMHO a 8"gyuto style is the best all around and a 6-7" santoku is best for veggies(if you use the right technique).

23 hours ago, BIGGUNDOCTOR said:This is a butcher's knife

-

4 hours ago, Lou L said:

Does anyone have any suggestions for removing the crud and scale after the heat treat?

If you're not in a hurry, let it soak in white vinegar overnight.

If you are in a hurry, a bench grinder with a wire brush will do.

If you ever get warps (there will most likely be some), you can try to correct them right after the quench while its still too hot to touch without gloves. If you want to take your time, fix the warps between 2 tempering cycles while its hot.

-

If your main concern is warping, i would normalize them before quenching. Annealing makes the steel softer but a good thermal cycling helps more with the warps.

-

Zknives database has interesting info on H1 steel. Spyderco uses it for their diving knives. According to them, it has the best corrosion resistance. From my understanding, it has to be work hardened to obtain useful hardness.

It's a shame H1 isn't made available.

-

-

107# PW I paid 200$ CAD. Had one edge completely busted. Rings great and very good rebound though. I managed to dress the edge without removing too much steel. Around 1/4"

-

56 minutes ago, Will W. said:

Joel

The only reason i didnt recommend aeb-l or nitro-v is because i dont know much about either steel, never worked with them. I have worked with both steels i listed though, and got quite a nice edges on both. Perhaps not razor edges though. I tend to only recommend that which i have worked with myself. Sounds like Aeb-l would make a nice razor, however.

I hope I did not offend you. I didn't work with those steels either but I did read a lot. In fact my gf says I spend too much time reading about knives and steels

Chisel ground santoku

in Knife Making

Posted

A hand forged Japanese blade sold commercially by a high end cutlery dealer in Montreal. You guys sure like to gang up on people.

So now tell me, why would such a respected and esteemed institution sell a knife that's unsuitable for the kitchen?