Irzy

Members-

Posts

12 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Irzy

-

I think I got it dialed in now. Thank you to everyone that has posted here. https://drive.google.com/file/d/0B6YXAegBrncVd0RxbTN1R3VuMDg/view?usp=drivesdk

-

I do have at my house an electric blower (for winterizing the pool pipes)... 3.0 hp 120-volt three-stage bypass motor with long life brushes, producing 130 cubic feet per minute open flow and 160 inches of sealed pressure. If I right this up to it, Would this be too much air?

-

Frosty, Can you take a look at the video and see if the flame looks any better? I started off at less than 1psi and stopped at 10psi. I am assuming it is still a bit too rich but I think it has improved some. https://drive.google.com/file/d/0B6YXAegBrncVUTJoQ1VwQ0hfRmc/view?usp=drivesdk

-

Frosty thank you for the info. As for the CO2 this was just a test fire and the forge was inside the garage for only a few minutes. Any extensive burning is done outside. My mixing tube is a 3/4" x 6" black steel with a 3/4" to 1" reducer. I just went out and bought new MIG tips that are smaller as well as a 3/8" to 1/4" reducer with all new 1/4" fittings to allow more air in. Tonight once the kids go to sleep I'll get to tinker around and try to dial it in and get more torch less dragons breath

-

-

As the title states I have just finished building my first forge. I have tested some 3/16" A36 angle in it as well as 3/4" A36 round bar. It seems to work but I do have a few questions. My main question is how do I know if gets hot enough for Forge Welding? I eventually want to make some Damascus. First off my forge is a single burner propane forge made out of an old 20lbs propane tank. The front opening is 5"x3". The burner I made myself from 3/8" black steel with an 0.030" MIG tip. The spec called out the MIG tip threared into a 3/8" brass male spigot which is threaded into a 3/8" black steel coupling. This coupling is secured inside a 3/4" to 1-1/2" reducer. This design stated that OD of the 3/8" coupler and the ID of the 1-1/2" reducer allowed for enough air flow to be pulled in and an air regulator not required. I followed this design and have a 0-20psi regulator hooked up on my propane tank. I have a video I took when I first fired the forge and placed in the 3/16" mild angle. By looking at the video and flames coming out of the opening can anyone advise me if my setup would infact work for forge welding? If not any suggestions to slight modify my setup? Turns out my videos are too large. I will attempt to link them https://drive.google.com/file/d/0B6YXAegBrncVSFJOeDJUNkQ4Umc/view?usp=drivesdk https://drive.google.com/file/d/0B6YXAegBrncVelJQeU9rN0o4ckU/view?usp=drivesdk https://drive.google.com/file/d/0B6YXAegBrncVbkFzLUVPV0tDekU/view?usp=drivesdk

-

Thanks!! And I will check out those videos

-

Thanks for the info. I watch Alec Steele videos daily. I was going to start on the leaf but don't have any of the fullers required to add in the details. Excitment got a hold of me and I just wanted something tangible at the end of the day.

-

-

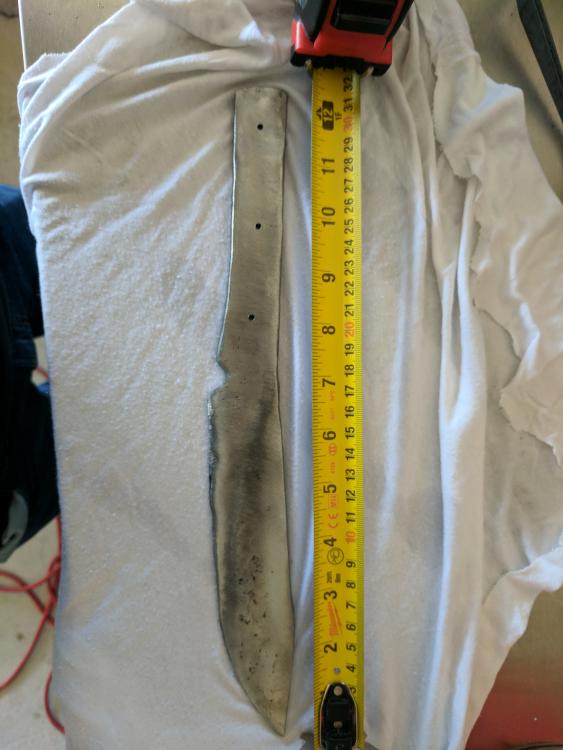

Hi everyone! I just started smithing literally days ago. Never hammered on steel or knew anything about it. Being obsessed with the show Forged in Fire I set out to build a propane forge and start practicing. This morning I lit the forge and placed in a piece of 3/4" round (no idea of the grade but it does weld easily???). Took me about 4hrs but I got a rough knife shaped object out of it. I kind of let steel do what it wanted too until a shape appeared. I found it fairly difficult to move the steel and make a flat from the round bar. Any suggestions to help improve? Maybe ways or places to strike that you have found to draw material out more easily (width I was able to figure out but lengthing was almost impossible). Many thanks and I hope to participate in this forum more often as I grow as a Smith.

-

I switched to fresh every 12hrs or so. The last attempt was in there for around 3hrs with new. Nothing occured Thanks, I'll give the 6% a go before welding it on. So far she's turning out pretty good. Just need to weld and swap out the regulator with one that is high pressure.

- 4 replies

-

- galvanized

- zinc

-

(and 1 more)

Tagged with:

-

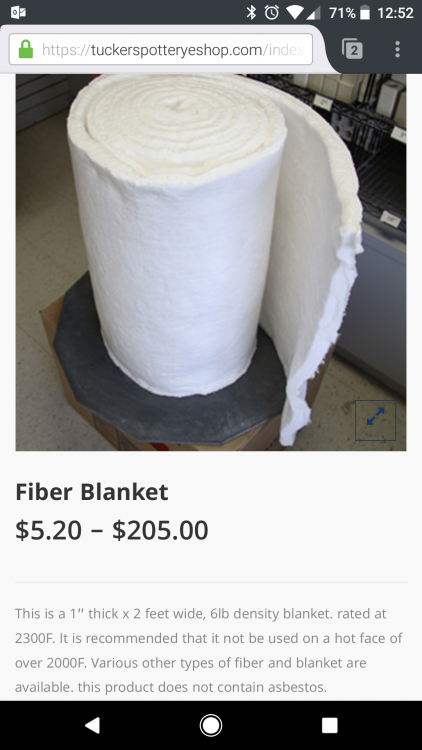

Hi All, New here and I could not find the proper thread as I am sure it has been fully discussed. So I do apologise for bringing this up... Again I am in the process of building my own forge (never hammered on steel before). I have a 2" pipe that is Galv. That I want to use for my burner intake (hardware store only had up to 1 1/4" in black steel. I have placed the pipe in vinegar for 48hrs so far. Over the first 24hrs there were lots of recations and you could see the zinc being stripped. Now though, there is no more reactions and no more foam on the top. I am assuming the pipe has been stripped but it still looks like it might have Galv. Still on it??? How do you know for sure? I have attached some images. The last is the pipe post vinegar 48hrs and scrubbed with a SS wire brush.

- 4 replies

-

- galvanized

- zinc

-

(and 1 more)

Tagged with: