Kevthefire

Members-

Posts

17 -

Joined

-

Last visited

Profile Information

-

Gender

Male

-

Location

Dunstable England

-

Interests

Harley's, Bushcraft, quark theorems (I lied about that to sound clever)

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

So I went the cheap arsed route and as advised I replaced the skateboard bearings with some ABEC9 ones adding another £4:99 to the cost of the build (£12:00 now) it runs quieter and tracks true so just a can of paint and i’m done. apart from making a 6” wheel and an adjustable work rest :-) cheers for the advice that i’ve received along the build.

-

Cheers for the ...well interesting reply Mark Thomas lol, I think part of the noise was one of the small rollers was catching on the platen plate every revolution. Thanks for the information on bearings, the new ones i’m Looking at are abec9. so I ran the grinder for half an hour sharpening everything I could :-) and here’s what I found: 1/ the heat generated softens the contact adhesive I glued the wheels together with.. 2/ the cheap Chinese belts don’t last long and have thick joints that bump the work piece every revolution 3/ I platen wheel shafts are too short, causing the nuts to back off. solutions are: redo wheels with epoxy resin and new abec9 bearings (£4.99 for 8) or take the plunge and buy a set of nylon wheels from Poland (£70 posted) buy better belts :-( replace the wheel shafts..

-

Hi Frosty, yes the crowning has helped I think, the rhythmic sound could be a duff bearing or the joint in the belt going over the wheels, i’m Going to order some sealed bearings tomorrow after measuring the sizes. I ran a couple of old knives on it and they shaped/sharpened up well

-

Hi Frosty, yes the crowning has helped I think, the rhythmic sound could be a duff bearing or the joint in the belt going over the wheels, i’m Going to order some sealed bearings tomorrow after measuring the sizes. I ran a couple of old knives on it and they shaped/sharpened up well

-

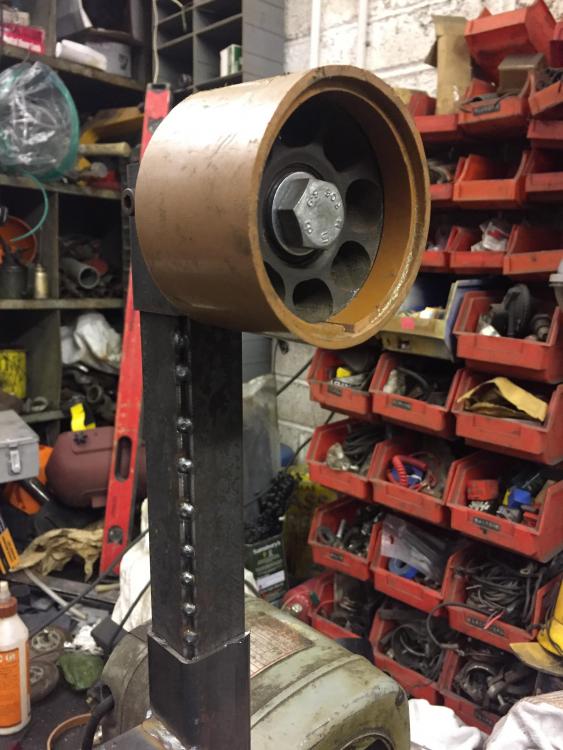

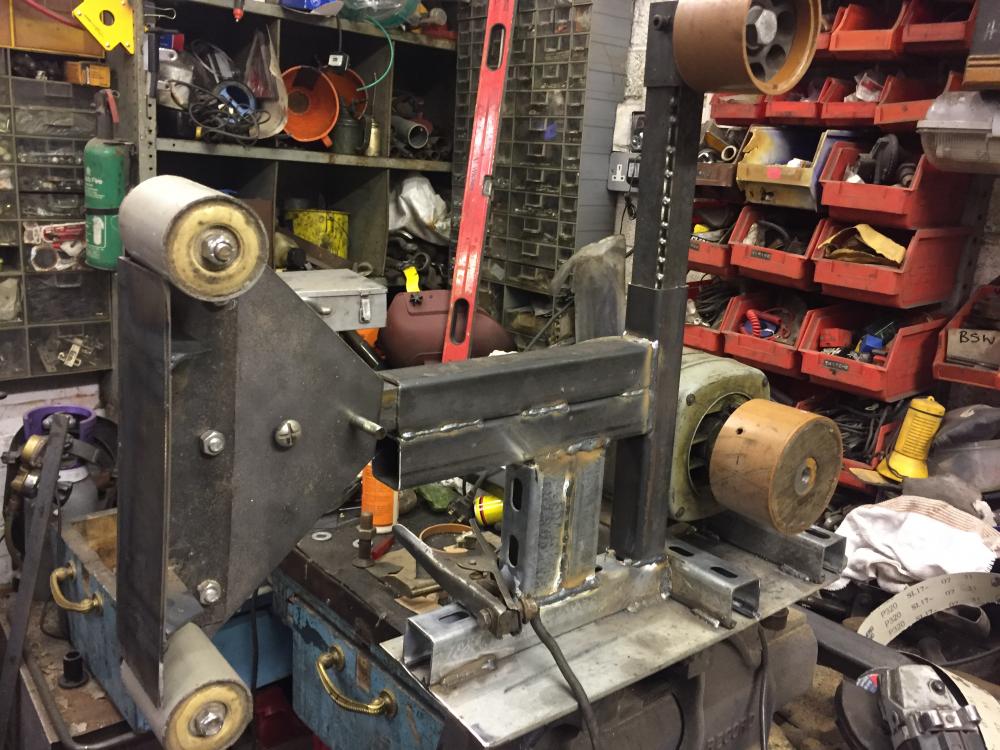

Today crowned the adjuster arm and made a lever to pull the tension arm in for easier belt replacement. Test run.. a little noisy but I’ll replace the skateboard bearings with something a bit better. I’m happy with the grinder that has only cost me £8:00 ( for the 6 belts from China incl postage) video below :-) cheers Kevin 69E3BED9-23EC-407A-80F5-291155FA821D.MOV

-

Cheers Frosty, I’ll use contact adhesive to stick another layer of pipe on then turn a crown to it on the lathe :-)

-

Ok.. did a test run tonight. 1/ the platen needs to be thicker or reinforced to prevent flex 2/ the box sections that slide into the frame on both platen and belt alignment pulley both need grub screws to prevent any movement... onwards and upwards :-)

-

-

Yes... tomorrow when I make it lol

-

I had a bit of a delay due to waiting for some 2x72 belts to come from China, 6 assorted belts for £7.09 including shipping.. they’ve arrived so now onwards again, I converted the 4” waste pipe pulley to a fixed wheel for the motor buy turning a shaft up on the lathe with a hole to fit the motors output shaft. I drilled and tapped the shaft and put in a grub screw to hold it onto the motor shaft I then welded up the frame parts that I could now cut to size with the belt roughly in place. I had a pulley wheel off a Land Rover belt tensioner that I was going to use for the adjuster wheel but a quick search revealed that I had no tubes to fit it, so I cut and glued some 4” pipe to fit. I also needed some box section to fit inside the box section I had built the frame from, another bodge required... 2 bits of angle iron ground to make a touch fit and then welded together... Tomorrow i’ll Get on with the tension wheel adjuster for belt alignment but i’m Please so for and it’s only cost the price of the belts from China :-)

-

What size is your motor wheel? Did a bit more today, started to make the platen and plate assembly, from 3mm plate, I hope it doesn't flex ( I'm thinking that when the platen and plate are bolted together it won't have any flex)

-

My tire hammer finally finished - video

Kevthefire replied to Stitch's topic in Power Hammers, Treadle Hammers, Olivers

Nice job, I look forward to seeing metal bashing videos -

Thanks for your thoughts, I have looked at plans to get ideas and see how to adjust belt alignment but I want to build my own grinder not copy someone else's .. and I enjoy making things for myself :-) "Far better it is to dare mighty things, to win glorious triumphs even though chequered by failures, than to take rank with those poor spirits who neither enjoy much or suffer much, because they live in a grey twilight that knows not victory or defeats"

-

Hi Frosty, I'm completely winging it, I think the motor is 3/4 hp, what diameter wheel do you have on your motor?, I'm waiting for some more steel before I can carry on .. cheers Kevin

-

I want a belt grinder but I can't afford one.... i know I'll make one with the stuff I have laying around, I have an old hoover electric motor and some bits of metal to start the frame, and some skateboard wheels. i turned the skateboard wheels down on the lathe to fit into some plumbing waste pipe, 2 skate wheels into each wheel, then for a bigger wheel I got some sewer pipe, I turned down 2 disks to fit inside the pipe from some oak floorboards and drilled them to fit some wheel bearings in... I've ordered some belts from China and I just need to make a drive wheel to fit the motor and loads of other stuff but I'll keep updating as I go ...