-

Posts

71 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by 19Branden86

-

-

Thank you very much! Definitely something I hadn't thought of. I appreciate the advice!

-

-

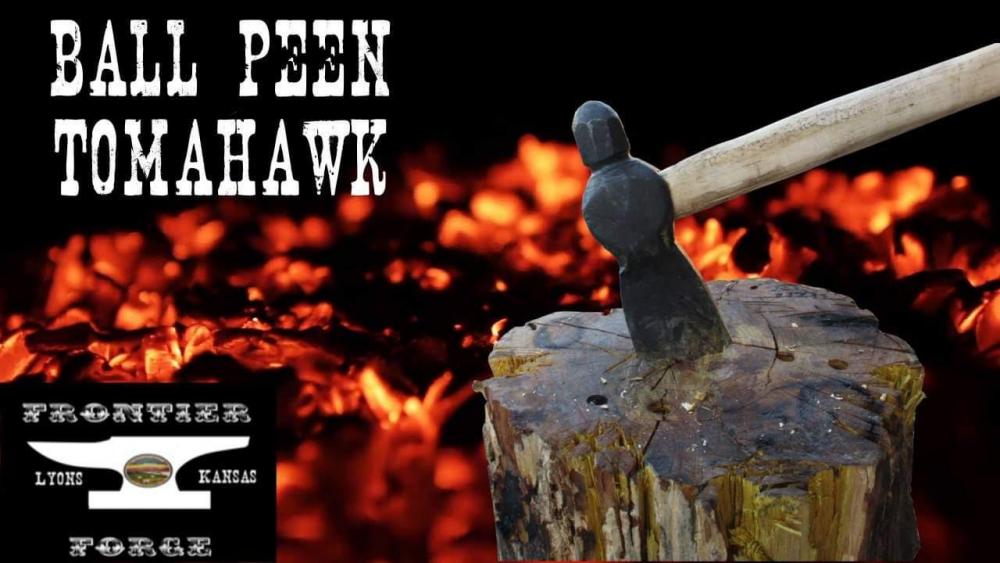

Thank you. It was actually a lot easier than what it looks. Just 2 pieces of round bar twisted in opposite directions and then the ends forge welded together. I have a video of it on my YouTube channel, Frontier Forge

-

-

-

-

-

I've heard that. And I've heard that 52100 is a bear to work no matter what you do to it. I've never worked it before so I couldn't tell you if there's any truth in that.

-

Yeah I kind of try and be cautious about heat treatment. If only one part needs to cut, like the end of an edged tool, chisel or something, for example, I only harden and temper that section. The whole thing is normalized beforehand. I rarely anneal unless I'll be filing on something right out of the gate. I figure just the act of heating it to forging temperature is enough to soften it for hammering on, depending on what SAE grade of steel you are working, of course.

-

Oh, I see. My bad. I thought I had said that in the original post but I see now I forgot to put the ht details in. My apologies, my friend!

-

I only quenched the tip. Only about an inch or so from the very tip. The back is soft so it doesn't shatter upon striking

I only quench the working end of my tools. As you can see on my cold chisel from one of my videos that gets used very regularly at work, the strike end is soft and slightly mushrooming while the cutting end is still as was after quench and temper.

-

Thank you, Dave. I tempered the point to straw yellow. I had normalized the entire thing before quench. Then after I quenched it, I took my little propane torch to it a few inches up the shank and ran the colors. I couldn't tell you if that is the proper method or not but it seemed to work. It holds a point well.

I actually recorded this one as I made it to upload to my YouTube channel. I made a channel in the hopes that I could get some critique of my processess as I'm working. I can make something that looks good but maybe I used a harder than should be way to get the result if that makes sense. And, that's actually how I came about trying that hexagon. I have a pry bar and cold chisel video that a smith from Indiana had commented on trying a hexagon, and that resulted in this center punch.

-

Thank you very much. And I am indeed a beginner. Not quite 2 years into the craft.

-

-

Ausfire, thank you. No, this one I didn't put a crow foot on. I work full time as a welder. The parts I weld are on jigs and as we all know, heat expands, so sometimes they need a little coaxing to get out of the jig. That's what I made this one for. I like the pun you did there

-

-

Hey, thanks a bunch guys. And I like the smart alec answer because I never thought about it like that but it makes sense!

-

I know some people make knives from old files. I have some old Nicholson pipeliner files that have damaged and rolled teeth. I'm thinking about annealing it and grinding down the tang to make a graver (may have to forge down part of the body behind the tang so as to have enough length for an engraving chisel). My question is, would file steel be good enough to work for this application?

Edit: obviously would need hardened and tempered afterwards

-

Forged leaf key chain from 3/16" square bar.

Let me know what you guys think!

You-tube link removed as per ToS, If you want to show a picture, then just post it

-

Thank you very much! It took a few weeks to get everything nice and shiny

-

-

-

Sorry I haven't been posting much. Been busy. Here are a few things I've been working on:

Dinner bell triangle, chain links (I needs my forge welding practice! Haha), Work in progress skinning knife from a piece of 1084, coil spring hold fast tool, and some cabinet pulls. I'd like to do a Suffolk latch in the future if any of you fine fellows have any pointers.

-

Thanks. Further south of Salina. Lyons

Basic Drawer Pull

in Member Projects

Posted

I wanted to do some hammer control exercises that involved drawing out over the edge of the anvil, since this isn't something I do often. I figured a good project idea would be making drawer pulls and isolating the finial material over the anvil edge versus isolating it with a fullering tool like I usually do.