-

Posts

15 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by Happy Fish Forge

-

-

Needed a V shaped hot punch for a project so I scrounged through my limited scrap pile and came up with this very rusty 1/2" drive breaker bar that I picked up at the scrap yard. Cut off about 7" and threw it in the forge. Got the business end to the required shape and decided to heat treat it. Not because it will need it but things are a little slow and I figured why not. Got it past nonmagnetic and quenched it in oil. A file dug into it like it was made of wood. Tried again with the same results. Tried a third time but did a water quench and the file still dug in. I picked up the other half that I cut from and wire wheeled the heavy rust off and there it was just as I suspected "made in China". Another piece of imported crap.

-

I found an old masonry chisel at the scrap yard. Hammered the beat up double bevel into a single for no other reason other than I like the reasonably clean cut the flat side makes. Didn't have any 1" square so I used 4 pieces of 1/2" for the shank. A little time on the belt grinder and it works fine with no heat treatment.

-

I make the analogy of the tools in my shop to the wildlife here in S.C. From bugs to gators, everything has teeth and everything wants to eat you.

Although not actually considered a "tool" the item in my shop that I consider the most dangerous is the propane tank. We recently had a local person die from a propane tank explosion. The investigation results ruled out human error and laid the blame on a faulty tank. Whether he knowingly continued to use a problem tank (people do idiotic things) or it was just extremely bad luck only he knows.

-

Yep, the neighbors and the H.O.A would have a fit. At least they cannot control what I do in my garage so I'm using propane and no hammering at night. Not use to having neighbors but got lucky and we are on friendly terms ... I'd like to keep it that way.

-

After 40+ years of living in the country we relocated (her idea not mine) to a place where the weather is more suitable to our old bones. Prior to moving I had been doing welded scrap metal art and had a sizeable scrap pile behind the barn. The downside at the new place are the rules and one of them is no outbuildings so I hauled 2,700 lbs. to the scrap yard. Recently got into forging and there was a lot of material in that old scrap pile I could use now.

-

Good to know, I've got an old Cocobolo mallet left over from my woodcarving days.

-

-

2 hours ago, gote said:

It is also possible to "bend back" by laying the to be edge on the anvil and strike the tip. The contact surface with the anvil is long unlike the contact to the hammer so the "blunting" is usually very little and can be corrected in the next heat.

Thank you for the advise, I will remember that next time. Actually I was aware of the need to "bend back" prior to drawing out the blade. New to forging I was concentrating on heat and hammer blows and simply forgot to do it.

-

5 hours ago, Frosty said:

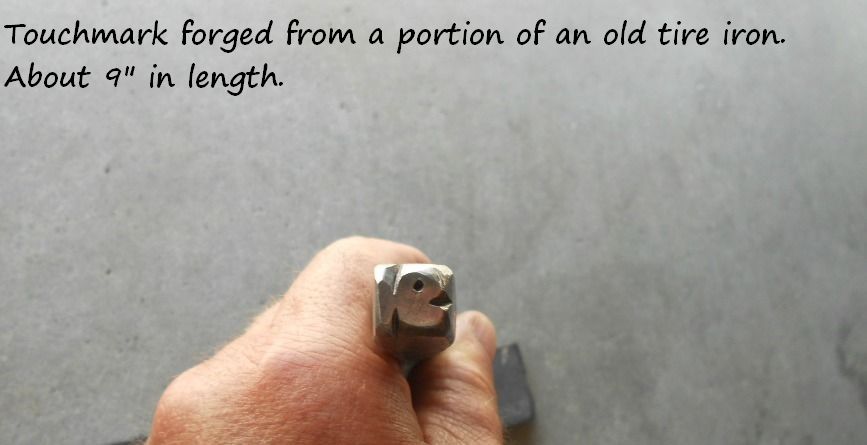

Welcome aboard, glad to have you. That's a great touch mark, I wouldn't change it a bit.

Nice anvil, have you radiused an edge? You need at least one edge radiused so you can set a shoulder without a sharp inner corner making a stress riser.

Going to buy or build your forge?

Frosty The Lucky.

Thank you and I agree the touchmark is fine as is ... everything else needs to be better

Yes, I radiused the edge on the opposite side of where I stand while working.

I built the forge with about a 170 cu.in. interior and one burner. In a corner of the shop I have an old 20lb. propane tank. Removed the valve and filled with water and bleach twice in case I decide to go larger with 2 burners.

-

5 minutes ago, Latticino said:

You are off to a great start. Keep up the good work.

Very nice anvil and stand. What are you using for a forge?

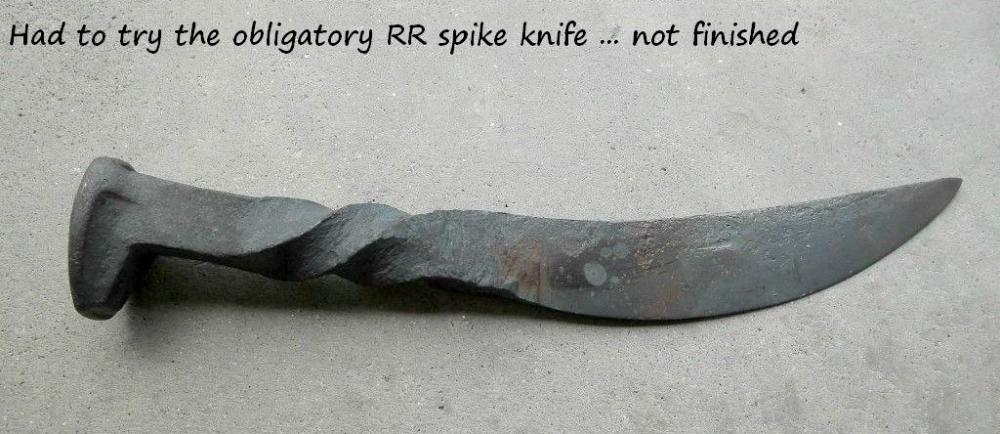

A tip: if you don't want to fight the "upwards banana" curvature of your blades, pre-curve them in the reverse direction before starting your bevels. The steel will always attempt to curve up and away from the edge being thinned out.

Thank you for the kinds words and advice.

Coal was my first choice but that would get us thrown out of where we live so I settled for a single burner propane for now.

Thought i had the upwards banana curve figured out but got lost paying more attention to the half twist.

-

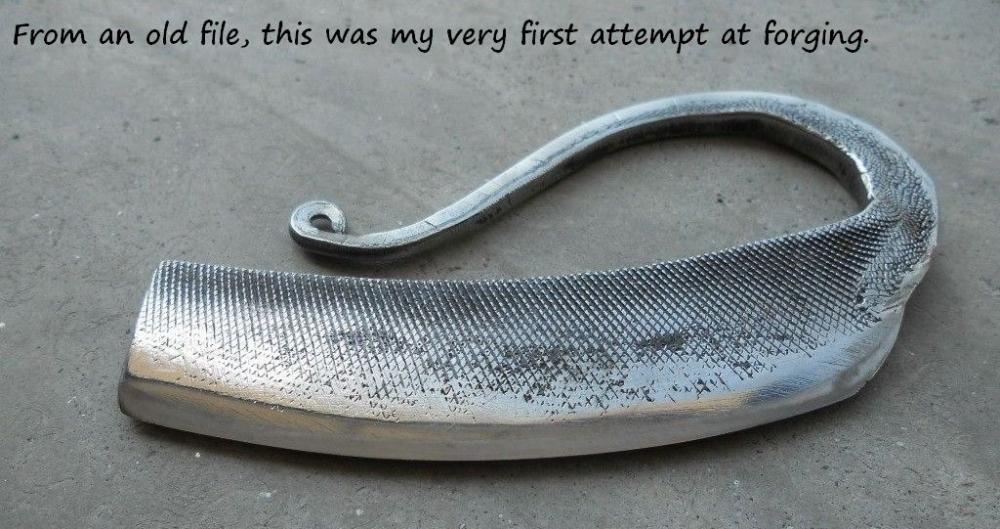

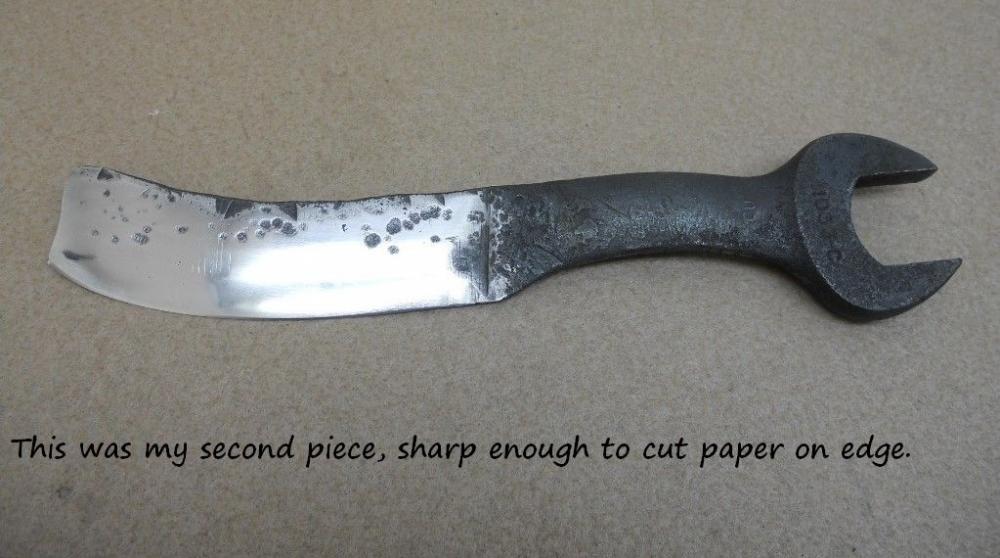

68 years old, needing a new hobby and thought I'd try my hand at smacking steel. I had limited welding experience many years back but never forged a thing. After 6 months of trying to find a decent used anvil I bit the bullet and bought new, pricey but worth it ... at least in my humble opinion. Built a base for it and made 3 pairs of tongs. The first 2 pairs are not very pretty but serviceable the third is a little better. I gave a try at creating a touchmark and it came ok, when I gain more experience and the work gets better I may even get to use it.

-

I live in my garage, I only sleep in the house.

-

2 hours ago, ausfire said:

Blobs of mig weld, but there are other ways. Hollow punches work well too.

Thank you.

-

Nice little critter, what did you use for his eyes ?

Show me your anvil

in Anvils, Swage Blocks, and Mandrels

Posted

I've recently changed hobbies and sold the anvil but I didn't have any issues with the hardy or pritchel holes, both were smooth.