Melw45

-

Posts

173 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by Melw45

-

-

Nice poker. That Dragon and twist would make a cool walking stick handle.

Thanks fo e sharing.

Mel

Than

-

13 hours ago, ausfire said:

Very cool. I can see tbem on the office shelf in a auto shop.

Mel

-

So is the anvil hollow?

Mel

-

Well this is on hold for now. The grinder and the rest of my shop are packed up because of the move.

I will post whin I get back to it after the move.

Thanks for looking!

Mel

-

That turned out very nice. I bet the church is happy with it.

Mel

-

On 08/26/2017 at 10:32 AM, Tommie Hockett said:

I may have missed it. So i do apologize if I did. But what kind of metal are you working with that you need a respirator?

ie; galvanized?

I am setting up a 2x72 grinder/sander. Breathing metal dust might aggravate my asthma. All joking aside metal dust is bad juju!

I am still waiting for the mask. Last tracking had it out for delivery then changed to incomplete address.

I called the usps and used the tracking number to schedule a delivery and gave the robo phone machine my correct address.

Here is hoping it worked.

Mel

-

Dylan

Thanks for that lead.

Mel

-

Wood

What are you useing for the engine?

Looks like a neet project.

Mel

-

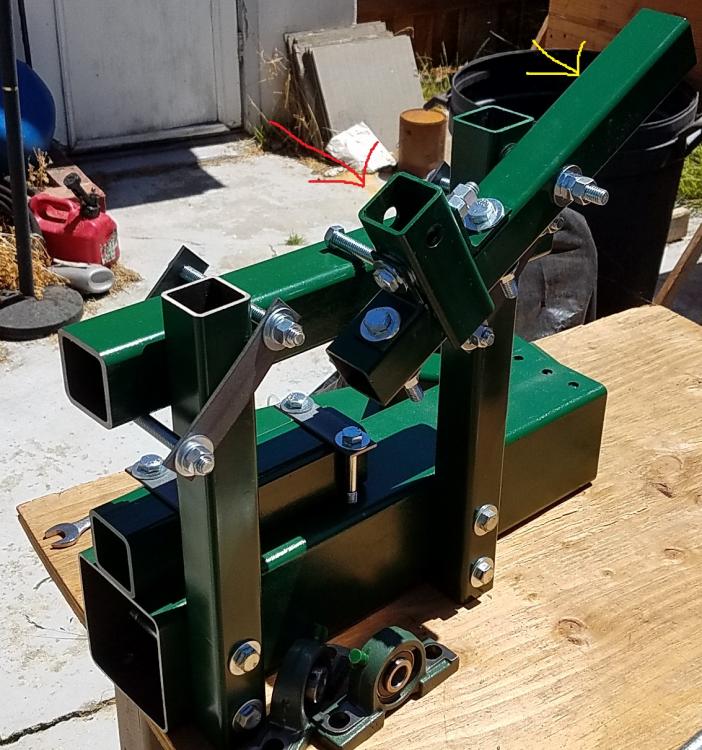

Update on this project.

Went by Harbor Freight and picked up a linked v belt and a grease gun for the bearings.

I was able to use a 25% off coupon.

Now all i need is to get some abrasive belts. Any one have a good supplyer for the belts that wont brake the bank?

Thanks

Mel

-

Judsson

Nice railing.

Mel W.

-

That looks beefy. What is the HP on that motor?

Mel

-

Frosty

How about some photos of yours?

Mel

-

-

I have one of these masks on order.

I will be looking in to converting it to a blower based fresh air system If that is not feasible I may have to shave.

.jpg.22916d26f679f2c5914b8ac38b566b2b.jpg)

Mel

-

-

I just tried the new bearings. Clamped them down and with a wack on the shaft they lined up ant turned free.

Looking good now.

Mel

-

The new pillow blocks arrived today.

I will be clamping them down to see if they have the same problem.

I will post how it go's later.

Mel

-

Lbs

I like your hammer. I showed it to my wife she said it was pretty.

Good job!

Mel

-

23 hours ago, Scrambler82 said:

Self aligning Pillow Blocks... ($$$), nice !

Just a quick thought, why not cut a plate, 1/4"thick, and use it to reinforce the tube wall, mounting platform, under the pillow blocks; you could mount it inside of the tube.

I can't believe the thin wall of the tube will hold up, just me so of course I over build everything, just thinking out loud, not meant to tell you what to do or go against anyone plans.

Good Luck with the new parts.

I might add a plate to the top. I would like the bearings to be further apart. They seem to be to close. I have heard of one guy that said he was breaking drive shafts. I think he might have had too much spring on the tension arm.

Mel

-

21 hours ago, Judson Yaggy said:

Electric or gas? If electric be careful, last I knew 6hp motors only existed in Craftsman brand fantasy shop vacs.

Gas.

Mel

-

My wife ordered me the step pulleys and i have ordered new pillow blocks.

The new one are self aligning

Mel

-

Only one available. So i bought all they had.

Silly guys wanted $99.00 for the rest.

On 8/21/2017 at 10:33 AM, JHCC said:Excellent! Now to hook it up to your power hammer!

Have to build one first.

That is a idea though.

Mel

-

Yesterday I went to harbor freight for some tie downs. Did get them.

They had some open box items marked down over 90%.

I scored a 6hp motor for $8.00. I guess it was a surprise to the guy that rang me up.

He did not seem happy about it.

Still sold it too me, reluctantly.

Mel

-

22 hours ago, Frosty said:

Ooooooh, nice little bench mill! I almost never need one but when I do, I have to make something else.

Frosty The Lucky.

I was pleasantly surprised as to how nice it was. I bought it new from harbour freight years ago. My uncle came by to look at it after I got it set up.

He is a machinist and i think he wanted it to be bad.but it tested out very good, flat and true.

When i moved it in we had 5 guys to get it out of the truck and on the stand. I moved it out with a hoist by myself. The wife standing by in case of catastrophe.

The worst thing was the wheel of the hoist stopped in a crack in my driveway. Needed a pry bar to get it out. The funny part was getting my wife to sit on the trailer tongue to stop it from rising. Pushing that mill uphill just was not going to happen. I had to convince her it was not a comment on how much she weighed just leverage.

Mel

I am back and new shop start.

in Building, Designing a Shop

Posted

Finally getting settled and have some time to start on my new shop building.

My dad and I got the foundation dug out and will get the forrms in over the next few days.

That is if it doesn't snow.

Mel W.