OlioReader

-

Posts

11 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by OlioReader

-

-

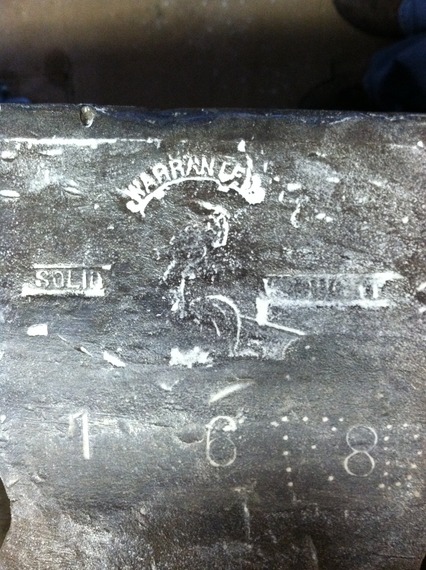

I cleaned up the logo a bit. After reading anvils in america, I am now sure that it is an arm and hammer as black frog suggested. I can't make out the weight under the logo other than a 0 1

According to Anvils in America The serial number of 1127 has it made in 1900 or 1901. There is also a 'C' stamped on the left front foot

I did a rebound test with a 1 inch ball bearing and got 90% across the entire face.

-

I used a rear rotor that was had the ebrake integrated. It's a bit deeper than a std rotor but not as deep as a drum. The center hole is smaller than the black iron floor flange used for the air pipe. I can simply drop the pipe in without using bolts. I then cut doughnut out of steel plate to cover the lug nut holes. It is held by an old steel lawn mower deck, and held up by cinder blocks.

-

Just the one above right now. It didn't get more defined in this round. I'll have to get a bit more aggressive to get it to show more. From what I can see it looks a bit like this (found online)

-

-

-

That is probably it. I bet these were homemade and application specific...

Thanks!

-

Thanks! I'll get some and see how she cleans up!

-

here are the pics I have. There isn't a cooling channel that runs the length. One of the pictures shows a second one that is made out of 1/4 round and it has a break in it that was repaired with looks like a brass solder. It is still a bit wobbly so if the fix was successful, it wasn't used in high torque situations.... I got these at an estate sale with a bunch of other steel dirt cheap. this guy had tons of large taps, dozens of files, cold chisels, antiques wrenches and planes.. I couldn't figure out the hobby that made him collect such a varied shop

-

-

I'm a passionate newbie at forging and finally got my home brake drum forge and railroad track anvil set up before Christmas.

I haven't had much of an opportunity to forge in January ao I've I've had time to peruse craigslist and I found this 96lb anvil and snatched it up. It has great rebound according to the ball bearing test and is flat across the face. The edges are a little beat up but not too bad in my opinion. It has two layers of paint so I can't make out the markings. Anyone have a guess to the potential maker? What is the best way to remove the old paint?

Luther bench vice

in Vises

Posted

I found this fun little bench vice at an estate sale. It is made by the Luther Grinder Manufacturing Co. (Milwaukee). The jaws are 2 1/2", opens up to 3 1/4 inches and weighs 11 lbs. It is in great shape; I just used a wire brush and put 3-in-1 oil on the threads to bring it back to good working order. I still have some rust to take care of, but it seems superficial. I've never seen a bench vice like this and I think it will work great for my small forging projects. I don't have a dedicated space where I can permanently set up my forge/anvil/vice so I won't need to carry my huge 6" jaw machinist vice to the work area.

I didn't find much about the Luther company. My internet sleuthing only brought me to a brief post on the vintage machinery site: " This company is known to have been active in the 1910s and 1920s, and probably for longer. They made hand-powered bench grinders." Not much else out there about them that I can find. Does anyone else have any ideas about the company or when this may have been made?