-

Posts

41 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by Hephaestus Smith

-

-

Hi here is a very easy and quick forge table, made from an old builders trestle,

step 1 slide out the top bar and put this to the side, this will be the table top.

step 2 , cut the upright at the hight you want, i went for 32"

now we have the upright and a H piece,

Step 3, cut the bar joining the uprights and disregard (this is the only waste also this is often 1" square tube and might fit your hardie)

, this will leave you with 2 uprights and a H

Step 4, take the piece we slid out on step 1. and cut to required depth of table. i went for about 28"

step 5, take the H piece and cut of the longer side of the H, (Keep these safe as they are very important for the final step.) then insert the " not a H any more" piece over and square it up of the front bar. you can weld it or tech screw it.

-

Thanks for all your comments, this was my first project other than fire side tool sets, and trivets. As i said at the start i am new to the whole forum concept, I really hope all you old timers know how much it means to people like me, that there is some where to ask questions.

-

hi Thanks for all your help

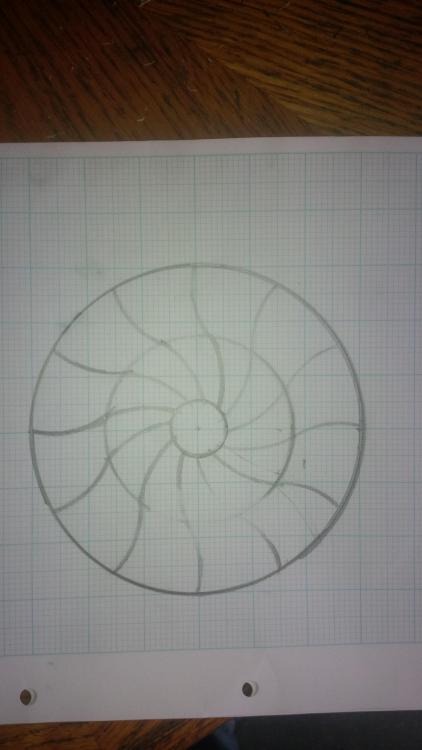

On 23/3/2017 at 0:49 PM, J said:hi all, thanks for all your advice it is much appreciated, i ended up making a simple roller with some left over scaffolding and a car jack. i also changed the design and used 30x6mm for the outer rim and 12mm square for the rest, here is a few pics of the project. Thanks again .

-

Hi Lads, thanks a million for all your replies, i think i will give VaughnT 's

idea a go, i live in Tipperary, Ireland so there is no workshop that could do it locally, with out fleecing me. we dont really have an equivalent of Harbor Freight here, Thanks again,

-

Sorry about that, its 1/2" stock not 12",

-

Hi All i hope i am doing this in the correct way, i am new to forums, i need to form a 1.5m (about 4' ) diameter circle out of 12" square stock, i need it to be as close to perfect as posible. at the moment all i think of is to cut a template out of 3/4" ply and try to bend some 30x6mm flat stock around it to make a form, but at 30 quid a shot for the ply and 12 for the flat bar its quite an expensive form for a 1 off, any ideas would be massively appreciated.

Thanks in advance.

Very easy forge build using old scafolding (pic heavy)

in Solid Fuel Forges

Posted

Step 6, take the 2 pieces you cut of in step 4 and weld half way along, place on your sheet, and cut around. i used 3mm mild steel but i have used 2mm before.

step 7, insert the 2 uprights, stand up, and cut out for your fire pot.

Step 8. weld on some edging to suit( and pieces of 100x 5mm around the hole i accidentally cut too big) throw in your fire pot ready for the final step.