Patman

Members-

Posts

15 -

Joined

-

Last visited

Profile Information

-

Location

Ruston Louisiana

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

IT passed well was a 100%+ on rebound from one end to the other.

-

Here it is just picked it up today, fresh from the wire wheel with a coat of oil brought it inside for some pics better lighting.

-

HAHA yeah better lighting in here for pics it is in my game room so she did not care help me turn the table for better pics of the other side..

-

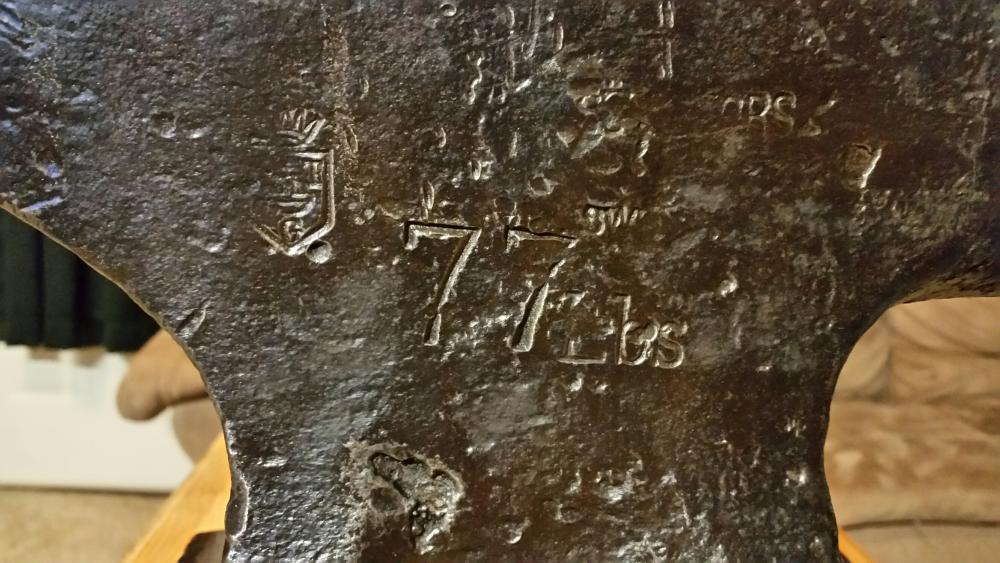

Yes I did, the Trenton though was covered with mud and rust could not make out a serial number. Here are some pics of the Soderfors cleaned up.

-

Well I am the proud new owner of the Soderfors Anvil, the ball baring would bounce back 100+ % from one end of the Anvil to the other. And the small pall peen did the same, decent ring and reflected back to the same height I would drop the hammer from with light strokes. Little deeper ring in the center with a high pitch ring toward the ends like a bell.

-

Okay well going see them this weekend providing the roads are not closed due to flooding, we are getting a ton of rain here. I did find out the Mousehold has had edge repair so you guys were right on the money with that one. I will be sure and snap many pics.

-

So bang for the buck would it be better to get one of these anvils or one from the Centaur Forge especially for a beginner like myself. I see the NC 112 lbs. Cavalry Anvil, for not much more then what I am about to spend on one of these older anvils, and I am not into the nostalgia thing I am more for practical and use. The extra weight would be a plus, but is there a major difference between what would be classified as a blacksmith anvil vs a farrier? Or would the 70 lbs be better for a beginner vs the Cavalry very new here so do not know the benefit of one over the other.

-

Well I feel better prepared to go look at these, I will do what you guys suggested in my testing I will post what I find and the one I buy thanks again so much for the help.

-

Thanks for all the quick responses and help greatly appreciated.

-

Well cost would not be an issue of the resurface since they would do it for free. Gov. projects as we call them are allowed here if done on own time and no charge..

-

Will do planning on going next weekend I will post them here. Is there any serial range and stuff I should particularly be looking for on the Trenton?

-

Just read up on the ball bearing test that should be doable since I have several around the house in the 1/2 and greater size from old tractor pto bearings will try that on each one. Thanks for the help, so looking for fractures and cracks or welds where it appears to have been repaired. I work with a company that does turnaround work in refineries and such and the QC manger here told me he could build/resurface one if needed we have all the preheat and equipment here they weld on large pipe and such doing boilers and reformer work. Any suggestions on that, he was thinking of preheating the anvil welding a buildup "if it needs one" then using wire wrap to let it cool very slowly.

-

The Fisher

-

I live in Ruston Louisiana, and no I have not seen them up close yet only this picture suppose to go look at them either this weekend or next I am working in central part of the state so not home to go to this guys house to see them yet. I know of the ping test with a hammer but I am very new sorry what is ball bearing test?

-

I am looking to purchase one of these anvils from a local farmer in my area could use some help on which one is the best deal/buy. Just learning have not even built my forge yet, but planning on using it primarily to forge knives, and such. Thanks