Buchan

-

Posts

19 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by Buchan

-

-

-

Interesting reading, thanks Steve.

-

Yep, just cheaply made rubbish.

Was in the shed tonight, got started on a box with a flap inside. Will have it finished tomorrow and post some pics.

-

For sure, PPE is part of my daily life at work and in the shed, not worth risking life, sight or limb for anything.

I've seen some horrendous injury's on building sites due to lack of PPE, there is no excuse for not being protected.

-

Hello Big gun and Theo,

I have hacked nearly 5 logs the size of the one in the picture, no problems yet.

I will let you know how it goes though.

I heated it till it was non magnetic then quenched in water, would it be better to do this but in oil instead? I have still to read a lot of info on this site but i'll get there yet.

Learning by mistakes is my method.....

Cheers

Iain B

-

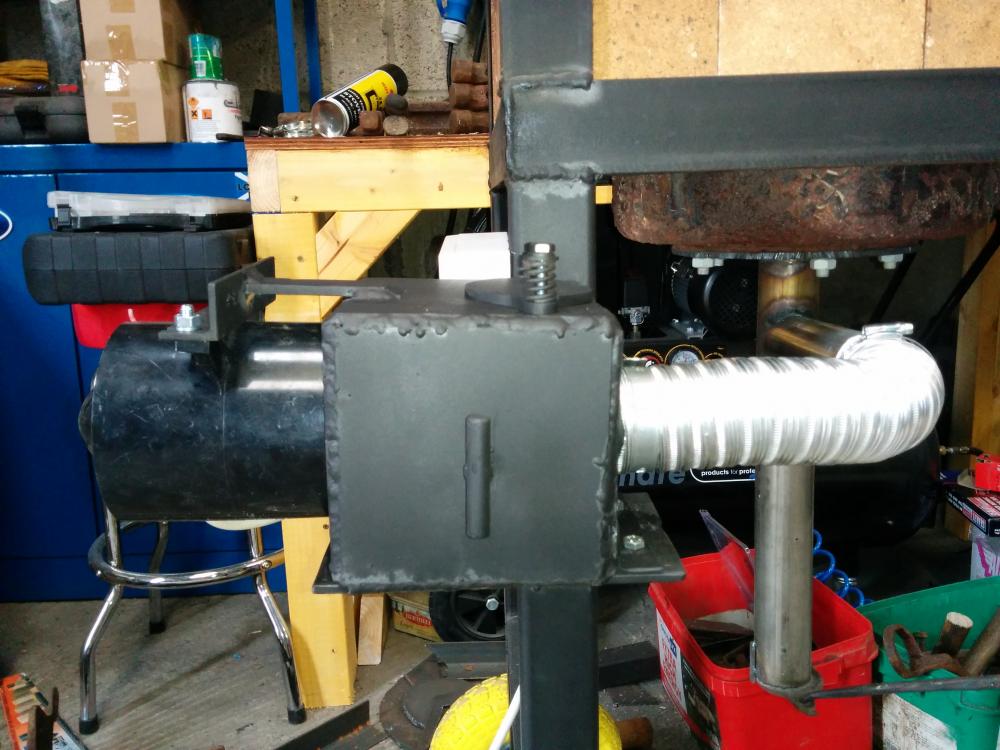

i have a 4" in-line electric fan unit that ill try. because of the smoke that comes back thru the pipe when i light the forge im going to have to make some sort of on/off flap which will also be a reducer from the 4" fan to the 2" pipe on the forge. ill work something out!

The postage to Scotland was the same as the cost of that hand crank blower, its disappointing to say the least. I have contacted the seller to see what he has to say but i'm not going to hold my breath waiting for a resolution.

Everyday is a learning day.....

-

-

.....he quenched it in water.

Cheers

Iain B

Frosty,

Is the inside of your flue pipe burnt out or does it just need swept?

If you had to replace it, could you run twin walled flue up the outside of your house instead of removing the existing flue?

Would be less damage on the wallet that way.

Cheers

Iain B

-

Hello Frosty,

I heated above the ground edge on the file teeth and let the heat run down to the blade.

It doesn't drag to much, as you said I hack it into the log and give it a twist to pop off the kindler.

Cheers

Iain B

-

Hello All,

kindling chopper made from an old 12" file, shaped the blade and bevels in the forge then went over it with the flap disc. i used the propane torch to temper it to a straw/gold colour.

Handle is made from an old hickory hammer shaft shaped with the flap disc.

Good heavy chopper that does the job.

Cheers

Iain B

-

Cheers matto!

-

Hello all,

Had the first burn of my brake drum forge today, used lumpwood charcoal to get a good base going then added 50/50 mix of house coal and coke.

The hand crank blower worked well and I got a good heat going. The thickest material was a 9/16th Allen key which I shaped into a punch, also made a hook to open the ash dump and a spoon for flux from old round stock that was lying aboot.

Great couple of hours messing about!

Is the left over coke re-useable or for the bin?

Cheers

Iain B

-

-

Hi tzonoqua,

thanks for the advice, i'm going to fire up the forge tomorrow. the local garage sells housecoal doubles which is small coal. I use it in the woodburner to make a good base for burning logs.

I will mix some 50/50 with the smithy breeze for the first burn and let you know how it goes, i can always change the mix either way from there.

Cheers

Iain B

-

Hello Frosty, that's great ideas, it wouldn't be a problem to fit a door and change the ash dump. I didn't even consider a backfire could happen, thank you for the insight.

I am a bricklayer to trade so i know how sore it is to be hit by high speed shrapnel from mushroom headed chisels and bolsters! I have in the past just buffed them down and i will do the same with the tools i just bought before i put them to use.

Cheers

Iain B

-

Hello iron dwarf, that's good to know. Looking forward to talking to other members and getting help with some projects.

I'm eventually i would like to make some gates for the house, but the first thing is going to be an axe made from an old ball-pein hammer! (gotta love Gary Huston for his brilliant you tube vids!) Get the old arm swinging again!

-

Hello ThomasPowers,

Yeah, i made the chimney cowl removable so the bricks come out easily for longer stock.

I would really have to de-water our yard as its still miserably cold and wet over here....56 degrees north!

-

Hello, New to the site and new to blacksmithing.

My name is Iain Buchan from the N.E of Scotland and today i finished building my brake drum forge, copied in the most part from Kevin Robinson on you tube.

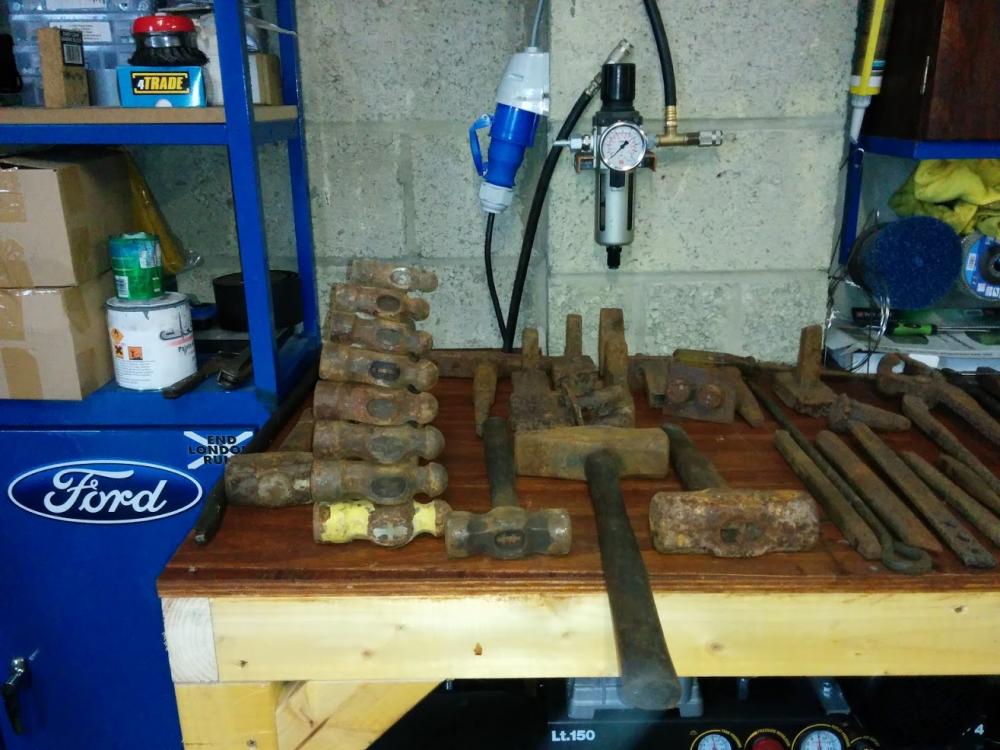

I picked up an anvil and cast stand at a sale last year for £120 and last saturday was at another sale and picked up a good haul of hammers, tongs, hardie tools and a belter of a leg vice for £180! Right place at the right time!

Im waiting on a couple of bags of Smithy Breeze coming so when that arrives ill get to heating some metal!

Cheers

Iain B

color temper chart

in Heat Treating, general discussion

Posted

Colours on steel, thought this might be interesting to someone.

Cheers

Iain B