-

Posts

114 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by mutant

-

-

Hi Ron, I'm a total beginner here as in I've only forged two things so far. I live on Long Island and was looking for classes as well. I used to attend an Art School in Manhattan called The School of Visuals Arts or SVA. They offer blacksmithing classes and they're held in Brooklyn at the teacher's studio. It's not cheap, but it's the closest I've found. I have not taken the classes so I can't tell you if they're good or not.

I'm in the process of converting a tiny part of a shed I built into the worlds smallest smithy. The goal is to be able to forge inside over the winter and be as quite as possible since my free time is only late at night.

- m

-

Yes I know - that's the learning part and not being the last furnace he builds.

-

By Crom! A sword worthy for a king!

-

Well, I say you did a great job. Use it and have fun. I'm sure it has benefits and short comings. No biggie, it's not going to be the last furnace you ever build. Make, learn improve! Keep us informed, I live for this kind of stuff.

-m

-

Very cool looking with 3 hardy holes. Maybe it was for production? A different hardy tool in each hole to speed up the work?

-

Thanks all for your input! I guess I should have explained the what and why. My smithy space will be very small and in part of a shed. I'm taking all the necessary safety precautions for fire and ventilation. My free time is mainly late at night so I need to be indoor and as quite as possible. I'm insulating and sound proofing the part I'll be working in with rock wool. The sound wasn't too bad, but I think the rock wool will help a lot.

I would love to build a side draft but I already have a rivet forge that i'll be using. I saw a thread where someone had the same forge as mine that they refurbished. It had a round hood and the sides where half inclosed. They even made a mouse door in the back for longer pieces. Mine just has a small wind screen. That's where my inspiration came from.

9 hours ago, Frozenforge said:Find some large pieces of cardboard, single layer like a cereal box and start bending, cutting till you get the final size and shape you need. You can actually make a miniature version out of paper to get the concept down. Then go full scale with the cardboard then get the appropriate guage sheetmetal that you can hand form and use the cardboard as a pattern.

Great idea! I actually started to do this.

-

Oh - I live on Long Island, NY.

-

Thanks for the feedback and suggestions!

-

Hey all,

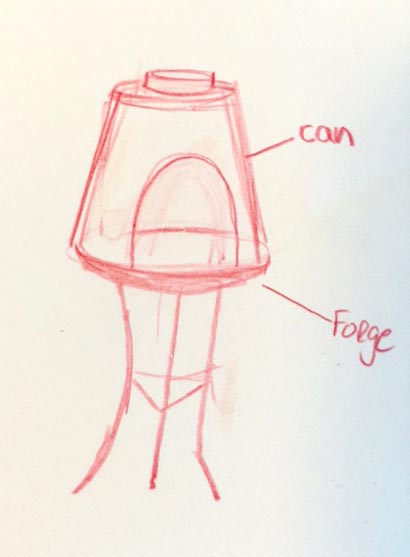

I'm setting up a little smithy and need to fabricate a hood and shield for my round rivet forge. My skills with sheet metal are non-existent, plus, the cost of ordering sheets the size I need is kind of expensive. I was thinking I could modify a metal garbage can but the issue is they are galvanized. I was wondering if I gave it a coat or two of BBQ paint, would that solve the problem? I attached a sketch since a pic with worth a thou.

Thanks for helping a newbie out-

-m

Devil Forge Single Burner

in Gas Forges

Posted

Like you, I almost pulled the trigger on one of their forges just to get up and running. I decided not too only because I've built a furnace for melting aluminum for metal casting. I have leftover kaowool and refractory cement plus, I have some experience with burners as well. I liked the bare bones approach of their set ups though and the price seem right.

Keep us informed about it- I'm still interested.

-m