-

Posts

48 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by Duckwalk

-

-

Hello all, ive been around here snooping for a while and have been in the chat. I just moved to Lincolnton, North Carolina and was hoping someone is near by. Id like to Get some equipment built back up. I just sold everything (again) to help pay for the moving truck. Let me know!

-

I like the part where he used a flatter to make his flatter

-

6 minutes ago, Daswulf said:

How sturdy is it? If you do make hardie tools for it i'd wonder about pounding on the edge. Give it a shot and let us know how it worked. It's already built. If it didn't work out you can always repurpose it.

Might add some support for the hardie side.

-

9 minutes ago, JHCC said:

Duckwalk, I would strongly recommend unspiking that plate from the base and turning it edge-up. You want as much mass as possible under the hammer blow.

I appriciate the advice. The whole thing weighs about 90+lbs. If it does not suffice for what im doing, i will absolutly try turning it up. I also have some rr iron that i use on its end.

-

Just finished making this today. The stand is 4 - 4x6 cut at 35". The "anvil" is a railroad tie plate. 1"thick. I can start making harty tools with rr spikes as bases as they fit perfectly for obvious reasons. This should be more than enough for me at my skill level.

-

Yeah i got the gear case top off. im just trying to find a model number on it. i would assume it has one.

-

-

-

-

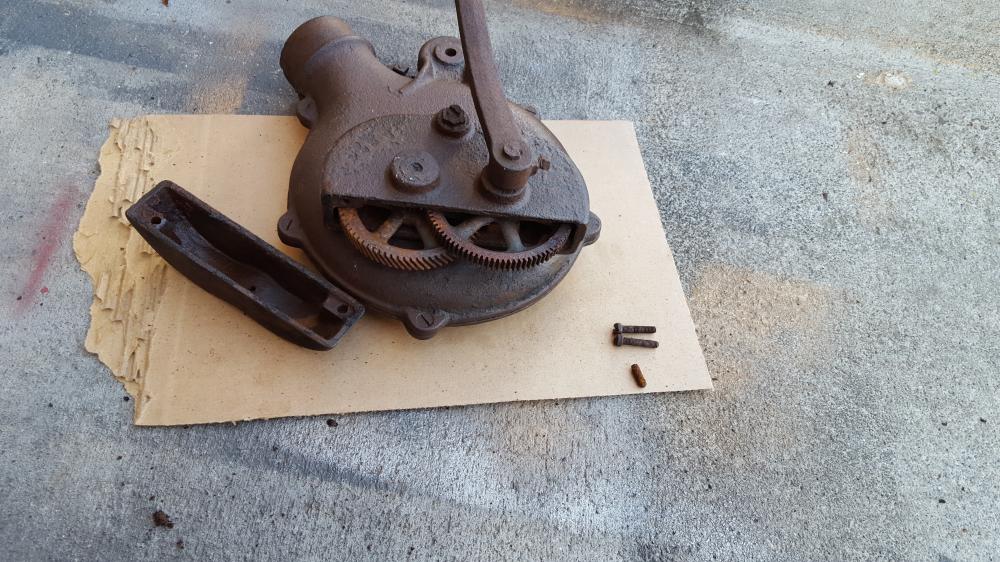

Well, the lid popped right off this morning! The gears seem to be in pretty good shape. Lots of rust between the teeth but thats all it is. nothing a little WD-40 and wire brush cant fix! There was a lose screw on the inside laying on top of a gear. im assuming some sort of locking screw to hold the gear in place?

-

I picked this up today for $30 and well as taken by suggestion from the chat room guys, im letting this puppy sit atleast overnight before i try and torque some screws loose that i have penetrating oil on. I will post the process of me restoring this to like day number one.

http://i99.photobucket.com/albums/l281/sesapex/20151207_132656_zpsonu79hvp.jpg

http://i99.photobucket.com/albums/l281/sesapex/20151207_132706_zpsnh1vxxpk.jpg

http://i99.photobucket.com/albums/l281/sesapex/20151207_132712_zpsglrj3kyi.jpg

-

If you have any balancing issues on the blades (IE: alot of vibration) I read somewhere that people were using rivets to balance them.

-

im not worried about time. ive got a hair dryer on the way but trying to get something non electric as i wont have power running to the shop im building. i dont mind fiddleing with it. i know he has working ones for $75.

-

So im going to a blacksmith collectors "yard" tomorrow to sort through and pick stuff out that i would like to purchase. he has plenty of small working hand cranks for $75 and alot that dont work for im hoping somewhere around $20. What are some things i should look out for? i talked with turbo in chat today and he recomend that i take some pliers, screwdrivers and an adjustable wrench wtith me. Then he had to go, once i get ahold of one that is frozen up or doesnt work, what do i need to look for as far as making sure its worth the $20 or so dollars?

-

Well, building myself a new forge to use. Its been about 6 years since ive smithed and im very excited to get back into it. Here i will post my process of building this forge. here is my firepot and a metal panel ive cut a hole in to set the rotor into. tomorrow i will build a table and will take pictures as i go.

-

This particular blade was a section of leaf spring from an older Nissan truck. unfortunately, this knife was also sold as a result of lack of income. Got a nice job now and i cant wait to get back to it! The handle was just some scrap wood i had laying around. cut the block in half, scorched it then put it on the polishing wheel. turned out rather nice.

-

Started as a teen smithing everything from forks to knives to S hooks etc... and had to sell EVERYTHING i owned blacksmithing related to make some house payments. That was a sad day

Recently starting to build a shop and get some gear to get started again. Getting a free forge from a friend today who got it free in a mill shop bundle purchase. Working on trying to get an anvil still. Just called a friend of mine in the crane business and he is going to get me 10ft of the following cable diameters

Recently starting to build a shop and get some gear to get started again. Getting a free forge from a friend today who got it free in a mill shop bundle purchase. Working on trying to get an anvil still. Just called a friend of mine in the crane business and he is going to get me 10ft of the following cable diameters

3/4"

1/2"

and 2 and 1/4"

-

Well first post here on IFI and i thought id post a picture of a knife i made a while back. This is the knife i am most proud of. The shape made it a bit difficult to heat treat and temper properly. Seems softer around the tip and the bevel areas. Would love to hear some feed back. I am getting my forge tomorrow but still in the hunt for ANYTHING usable to pound on. Im very excited to restart this in my life. I had to sell everything i had made tool wise along with my forge and anvil as i was out of a job and needed money quick for mortgage payments.

Re-Introducing

in Introduce Yourself

Posted

Is there a better place in the forums to post looking for people in my local area?