jester forge

-

Posts

16 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by jester forge

-

-

5 hours ago, Charles R. Stevens said:

Well, a 2mm ammo can comes to mind...

as dose a drum on a stool (remote) as many old school forges had a barel on a stand, cold out the bottom hot up tord the top.

i imagine an old radiator would work...

I have a 55 gallon drum I can cut down about half and I can use the other half for an anvil stand hmmm I agree with the ammo can idea but I only have a 30 cal ammo can and I'm using that for its intended use. Thanks for all the great ideas.

-

Ok thank you I'll post pics when I'm done( if I'm not ashamed of my welds lol) for the water tank for the tueyere what can I use?

-

-

1" ID

-

9 minutes ago, kubiack said:

I don't think you are going to be happy with sand as the base material. It will most likely fuse with the burning fuel and cause to much build up. I used dirt in my side blast at first and every time I used it the dirt around the fuel had fused with the clinker and coke into a shell. It wasted quite a bit of fuel and I had to replace 1/4" of dirt when I cleaned out and rebuilt the fire. I found a source for some coal ash and have been much happier with it. We have loam soil here and I think the sand was the main contributor.

Thank you I was worried about that

-

1 hour ago, Charles R. Stevens said:

How big is the tyere? Coal or charcoal?

1inch . Anthracite coal

-

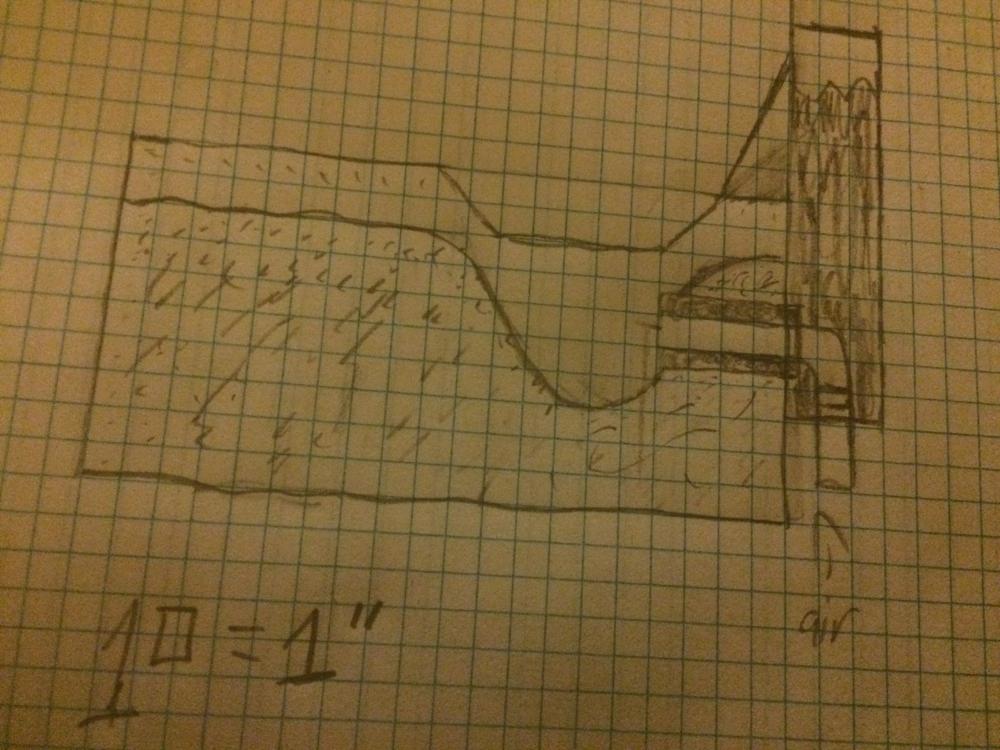

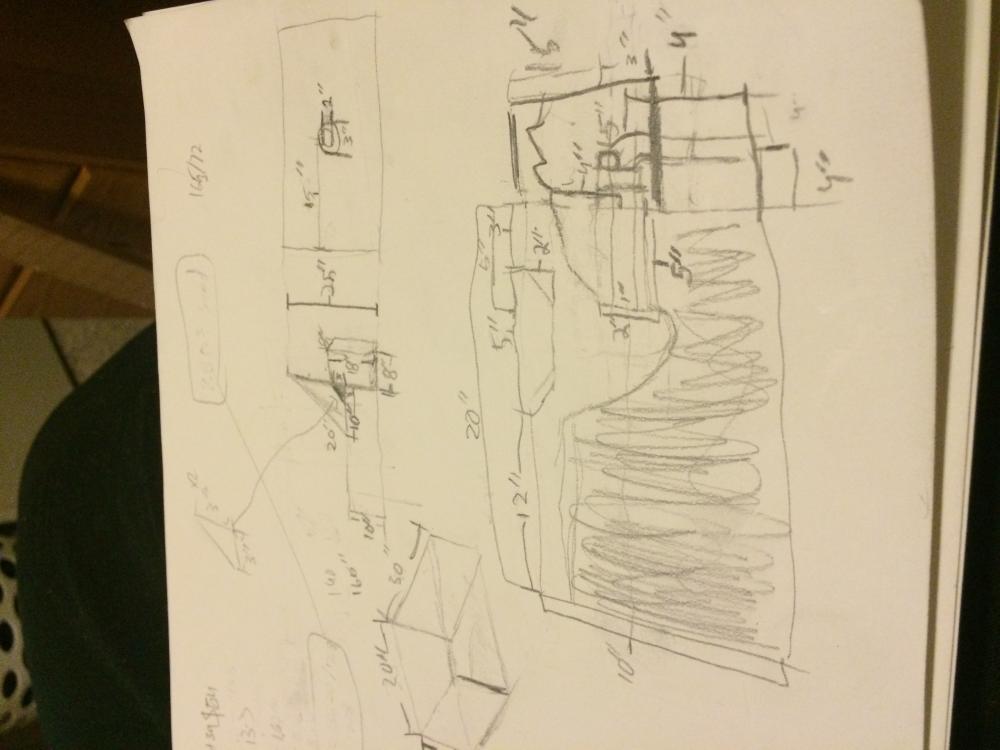

I just drew that real quick the other night to figure out dimensions and stuff i just haven't been able to transfer it to my graph pad yet and what scale do you guys usually use for the graph paper I'm real bad about that I always make it to big or small

-

30 minutes ago, Glenn said:

Photos or a drawing would be helpful.

We need to know where and how deep the fire is to be placed.

Are you going to use a water cooled twyere?

Yes I'm going to use a water cooled tueyere the drawing I have isn't the best it's a little sloppy and hard to read but here it is it's not to scale and some of the measurements might be off the middle of the air pipe will be up 6" from the bottom

-

I'm building a side blast forge out of 1/4" steel. It's 10" deep 20" wide and 30" long the fire will be 4" down and 5" away from the back wall. I will fill it with sand my question is will play sand be okay. And for the water tank would I be safe to use a galvanized bucket or will it get too hot

-

Yea the anvil is at a good height for me the vise I just use to bend small stock for hooks and small stuff like that

-

my vice

my vice my first blower

my first blower the forge

the forge my new blower

my new blower rail anvil

rail anvil tongs

tongs tongs

tongs  scrap

scrap fuel

fuelsorry for the side ways pics

Welcome aboard, glad to have you. You may not know how not to forge a knife but you certainly know one thing not to forge one from.

One small point, we LOVE pics: shop, tools, projects, pets, family, scenery, most anything you'd let your 7 yr old daughter look at.

Frosty The Lucky.

-

The main thing I need is a couple more tongs. But I'll make those

-

Once I get my phone fixed I will post a couple pics but until then. I have a brake drum forge a railroad track anvil. my blower is a hand cranked tiger blower that I restored. I'm looking at a hay-budden anvil on craigslist I'm just waiting for the funds. Haha!

-

I'm new to the forum I've looked around a bit but this is my first post. I'm new to blacksmithing I have made a knife out of unknown steel and it turns out it doesn't harden so I guess I'll use the rest of that bar for other stuff. Any tips for a beginner it would be appreciated.

Side blast

in Solid Fuel Forges

Posted

I already have most of it built I just need the cooling tank and sand or dirt it's cost me 25 dollars so far I had most of it in my " steel depot" haha.