-

Posts

21 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by sand

-

-

That sucks, it's happened to me so many times.

Interesting. Thanks for the info. When I get it unstuck I'll post more pictures.

-

I think it's Iron Age magazine.

-

-

Yes, The rear does move up the notches.

It's quite stuck at the moment but nothing a little(or a lot) of WD-40 won't fix.

It's not for sale at the moment. Maybe later, if I decide to sell it I'll let you know.

-

-

Now that I see the picture more clearly (I was using my phone before) the blades are definitely on correctly, It's all in the aerodynamics of the blades, if the blades were reversed the blower would not blow, the air would follow the curvature of the blades and move toward the center. As it is now, when the blades spin they push the air up to the edges of the blower and toward the tuyere.

-

Are the blades spinning to the left or right?

-

The blower blades don't move the air in the direction They are spinning. Being an inpeller, as the blades turn they suck air in through the hole on the side of the blower and consequently the air comes out the other side. So even if the blades look like they are pushing the air in a certain direction they are just sucking air in.

-

I don't think I would ever sell it, even if i got enough for a new anvil. I like old things too much, I have a house full of antiques. My house is an antique.

-

Hello and welcome from another new member of this awesome site. If I remember correctly Wayne Goddard wrote about it in his book The $50 knife shop. (this is the book that got me into blacksmithing) He calls it cable damascus. There is a whole section on the matter in his book (chapter 6), so depending on the material the cable is made of, I believe it should be possible.

-

I'll make sure to round the edges a bit I don't trust myself enough with a hammer yet to say I wont hit them.

-

There is no way It's going to stay unused in my house

-

It's a 200# fisher I picked up at an antique store. I'm friends with the owner and whenever he gets blacksmithing stuff he calls me. He said I have something you might like. When I walked through the door there it was. It does not have a mark on it. looks like it was never used. It still has the red eagle anvil sticker on it.

-

-

Yeah I was looking into doing that, I think it would be great.

-

Hello everyone. After lurking for a while I have decided to join. I got started blacksmithing like a year ago. After picking up a book on the subject at the local library and reading it I said to myself "I'm doing this" and off I went in search of tools and it turns out they were all in one place, The Windmill Ranch. The gentelman living there sold me all of his old blacksmith things the forge anvil hammers tongs everything he had for one low price. I could not resist I loaded up the truck and set it all up in the back yard. Since then I have been at it every day I can and I love it. I have tried bladesmithing, ornamental iron, and just hammering way and see what comes of it. I love evey aspect, its just to much fun. I guess I will end this before I get caried away. I think this will be a great palce to share ideas and get aquainted with other smiths.

-

This is my forge, its a little rusty but it gets the job done. Still needs a fire pot (I am using a piece of enameled steel and some clay for one at the moment.) and a hood, but since the forge is being used outside the hood is not that necessary in my opinion. I got it from the Windmill Ranch in Stockton Ca. along with everything you see here.

-

Hey guys this is my first post. I thought it would be appropriate since my first anvil was a Hay Budden. Serial # is 84002 though the 2 is stamped sideways, it also has 2 more two's stamped on the waist above the serial #. The weight stamped on the anvil 133# I have not taken the time to weigh it for the actual weight but from what i have heard they are stamped with the correct weight give or take a couple pounds. I got it from the Windmill Ranch in Stockton Ca. along with my forge and tools, they were all used by the gentleman that sold them to me. I purchased them all for $125.

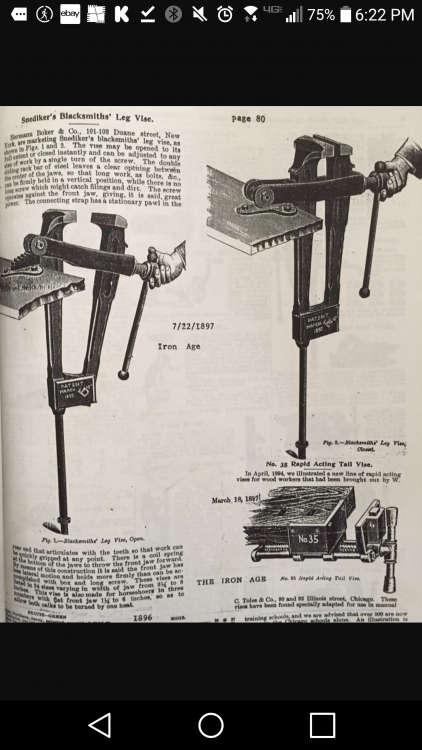

Never seen one like this

in Vises

Posted

While looking for the source of the image I used I saw that one was posted here but I forgot to look for it again. Good looking out. I'll look for it. Thanks