-

Posts

42 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by the_white

-

-

hello guyz,

I have come across this on internet and i tough i should share. It's an auction of a lot of blacksmith items in Baden Ontario. Here is the link with pictures and everything.

http://www.theauctionadvertiser.com/cgi-bin/slsearcx.pl -

I found this add on internet. It is located in kitchener ontario. Blacksmith vise 4 inches 80$. I find the price is good but i got one already.

blacksmith vise - Kijiji Kitchener / Waterloo -

why did you remove the prices that were under each description of the item?

:mad: :mad: :mad: -

I think it looks pretty but you should make it so you don't use any new part composite like those screws. It kills the medieval of it. Still looks good!

the_white :D -

Are you going to make him a sheet?

It's a pretty nice knife

the_white :D -

thanks frosty :cool:

the_white :D -

I would!

the_white

I'ill tell you today when ill see you! :p -

The guy sold the whisper mama. It's not really complicated, it looks like it but it's not that bad.

the_white :D -

I was thinking doing a 18'' long forge with 8.5 ID forge. It gives me a 1021.41cu/in inside if I'm not mistaking. I wanted to have a longer forge to be able to heat variable length of stock. But if I do so I need to put 3 burners in if I use 3/4'' burner like you said. Would it work at 2 burners at a bigger size of pipe? Or am I better to build a 12'' forge wich gives 680cu/in.

the_white :D -

Here is a website I found with a lot of knives designs with simple images. Tough it would be nice sharing:rolleyes:.

New Page 6

If you click on the different menu on your left of the page you will see there is different groups of knives and it will give you more drawing.

the_white :D -

Yeah you are right. I didn't think about it to much when I gave my measurement. It's even better. Just bought 2 7'' stove pipe. I will put them together like you said and I will get 14'' that will be just good when I will add my Kaowool like insulation.

the_white :D -

ok so I bought 2 4 feet sonotube, one is 8-1/4" inside diameter the other is 10-1/4" I.D. I was thinking 10" and 12" but I tough maybe it would cost to much gas for nothing. I didn't choose the length yet but I'm thinking maybe 18" with what you guys wrote. I didn't count the in.cu ill have inside yet but I will and I will adjust so I can have max 2 burners.

the_white

P.S It's Friday now, just finished work and I have to wait until Monday to do the road trip to go buy the stuff I need to build my first forge..... I'm already going nuts, I just wish they were open on weekends. -

ok thanks guys.I'll think about it.

the_white :D -

For the forge itself I was thinking doing like you said, 6 inches diameter inside. 34"-1" blue ram and 2" of kaowool like insulation. My question now is what length of forge should I build? I know it depends what you want to forge. I was thinking doing it 24" to 36" long. Considering the stuff is pretty expensive i want to buy the minimum I need. I was thinking to put 2 burners with a valve i can chose to close to run on only one burner. Any advise on that?

thanks

the_white :D -

In the same line of idea's I sent a message to the salesman of Vesuvius with the spec sheet of kaowool blanket to know if they have a similar product.

( http://www.thermalceramics.com/pdfs-uploaded/datasheets/americas/514-205.pdf)

He sent me this http://www.fabricationspecialties.com/pdf/cerwool.pdf

(I had to find a link on the internet so it's not exactly the one he sent me but I think Vesuvius blankets were bought by ThermalCeramics so this link should be appropriate. I didn't see a lot of changes in it).

I just want to make sure I can use that product has outside layer. I -

thanks for all the help!

thanks for all the help!

the_white :D -

Here is a link of what I'm talking about.Catalogue - SuperVent 2100 (JM) (JM002-E)

If you look under technical pipe data it explain it's a pipe 300 series stainless steel 0.016'' thickness has inner layer. Then there is 2'' of insulation and another layer of type 430 stainless steel 0.015'' thickness. I don't know if the pipe is similar to what you were speaking of. I was thinking buying that, cut it and remove the insulation and put both my plastic refractory and K-wool insulation. The only concern i have is it's only 2'' in between the inner layer and outside layer, and you advise me to put 2-3/4'' total materials thickness. Since it's stainless steel I was wondering if i could let the inner layer inside has a permanent layer.....just thinking about it while I wrote those lines I guess it would melt..... :mad:

.... Maybe you could link me a picture of the product you are speaking of, I think i got it wrong.

.... Maybe you could link me a picture of the product you are speaking of, I think i got it wrong.

Another one for you Frosty you said I should take the Technical Specification Datasheet Level 3

I called in today and it's not a regular stock for them. The guy suggested to take this one instead, saying it's regular stock and better. Here is the technical sheet Technical Specification Datasheet Level 3

Here is the MSDS http://www.vesuvius.com/lwwcm/techspec.nsf/22EE9E9F8C03F3CB85256B0A0052C63E/$FILE/LES10072-5.pdf?OpenElement

Here is the instalation procedure http://www.vesuvius.com/lwwcm/techspec.nsf/50394B7A8D0C1EDF85256CE2005B44F4/$FILE/LES1301.pdf?OpenElement

Here is the drying and firing http://www.vesuvius.com/lwwcm/techspec.nsf/DBF338AF0301A95085256CE50068D5D3/$FILE/LES1801.pdf?OpenElement

It is worth BLU-Ram HS @ $ 40. 61 / per box of 25kg. (Canadian price)

Do you think this stuff would be good? --------->>>>> thanks again

the_white :D -

You can look in blueprints sections Blueprints | articles.

Here is all the websites I found searching through internet!

Plans Available

Building the new forge

Building the forge

http://ironringforge.com/

BP0115 5th Wheel Forge | Blueprints 100-200

I Forge Iron Blueprints

Zoeller Forge

Free Gas Forge Plans

Riser's Small Propane Fired Forge

Ron's Forge Page

DIY Propane/Natural Gas Forge

Freon Tank Propane Miniforge

http://metalcast.boorman.us/reil_1.htm

Forge Making

Air tank Forge Build

Most of them are linked to a forge plan, but some you have to look in the website because they actually have more then one plan.

YAY my time to help back!

the_white :D -

Look on Refractory supplier - Refractory products - Ferrous and non-ferrous foundries maybe they have a store near you. I search a lot for a retailer and this is the good one I found.

the_white :D -

Ok thanks for all the information. It's a chance I work in building supplies store

, I will try and see if we have any damage insulated pipe to get it cheap.

, I will try and see if we have any damage insulated pipe to get it cheap.

the_white :D -

I'll have to read it again but I think I understand your concept (hehe main language is french

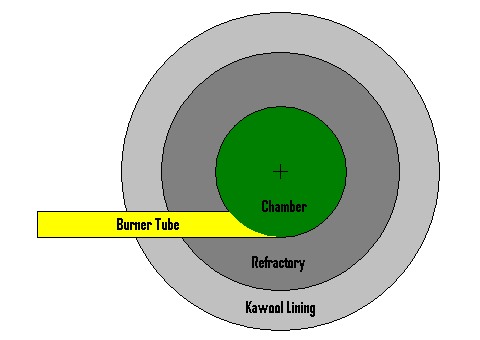

). I was thinking of doing my forge inside an air tank or something. So if i do it in between 2 sonotubes, after I remove the cardboard, will I be able to make it tight enough to the k-wool that it won't move all the time. For the image burner position, you have to remember i took this image on a foundry based plan which heat at the bottom when the foundry is at the vertically, which I'm not gonna do so I am probably going to but in sideway like most people do.

). I was thinking of doing my forge inside an air tank or something. So if i do it in between 2 sonotubes, after I remove the cardboard, will I be able to make it tight enough to the k-wool that it won't move all the time. For the image burner position, you have to remember i took this image on a foundry based plan which heat at the bottom when the foundry is at the vertically, which I'm not gonna do so I am probably going to but in sideway like most people do.

the_white

P.S you guys reply so fast I had to refresh before posting just after reading at longer frosty post hehe. -

Ok good to know. But is it pourable like a cement so I can make the inside of my round forge layer?

Thanks for your time!

Thanks for your time!

the_white :D -

Great reply has always frosty. My only question is the product you linked Technical Specification Datasheet Level 3, is it a cement? I read plastic refractory...

I ill see if they have it in stock tomorrow. If they do I'm planning on going to buy the stock Monday. It's on the Quebec side near Montreal. I'm from Gatineau so if anyone near ottawa region need some stuff, now is the time to talk!

the_white:D -

Thanks for the price check information. Only thing is I'm doing a propane forge, I think you are speaking of a coal forge pot. Your information are still valuable to me, I will translate them on my project.

the_white :D

A knife.

in Knife Making

Posted

Good job, I like the sheat!