ron2k_1

-

Posts

10 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by ron2k_1

-

-

20 hours ago, Buzzkill said:

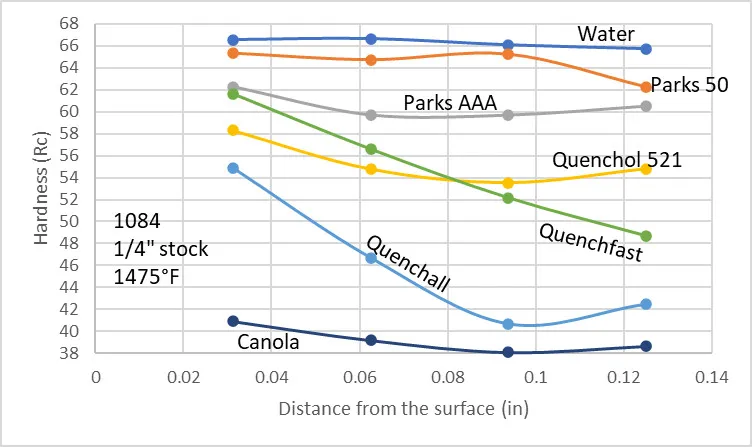

No. That is a chart of hardness of 1084 with different quenchants at the same thickness (1/4") and quench temperature.

We're both right. Yes, he quenched a 1/4 inch stock, but to get the chart, he grounded both sides of the stock to test for hardness at different grounded thicknesses.

Sounds like a plan then. I really still want to test canola and I've heard that hydraulic oils (used for heavy machinery) are good as well, so at least I'll have some sort of slow quenchants for other varieties of steel.

Thank you all.

Rony

-

Hi. So, in another thread I was recommended to cast 3/4" to an inch of castable refractory over rigidized insulation in my forge. A member there recommended Kastolite 30.

I tried purchasing online and the company that sells the 55lb bag, for some reason, doesn't want to ship to Houston Texas.

Are there similar products like Kastolite 30 I can try buying, or do you suggest a supplier that sells online and would ship to TX?

Ron

-

Thanks everyrone. I found Parks 50 by the gallon very reasonable on Amazon with prime shipping. My shipper and I can then workout the logistics to Belize.

On 8/16/2023 at 2:25 PM, jlpservicesinc said:I use Linseed oil in the trailer since it's handy and great for making springs.. So it gets used for nearly all the hardening while in the trailer.

I don't know if it's a fast oil or slow oil....Depending on the steel you used for the springs, Linseed or Canola would be adequate. Dr. Larrin shows that for 52100 or 5160, a medium quenchant is optimum in his opinion (from Knife Steel Nerds)

However, for the type of steels I intend to use (as a beginner), 80CRV2, 1075 etc, he recommend a fast oil (Parks 50 or even the AAA). And his tests shows to not use Canola (the hardening in Canola is outrageous!!). This is a chart of hardness of 1084 with different quenchants

I've always believed that as a beginner, you should set up for maximum success. When I was learning to weld, I was cleaning all my surfaces and clamping everything square. I'm still mediocre, but after some practice I stopped cleaning and just cook rusty crummy joints with 6011/10, and I start weld slightly out of square to end up close to square after shrinking. So I think I'll just bite the bullet and buy couple gallons of Parks and use Canola for leaf spring and those kind of things after some tests.

Ron

Mod note: typo removed

-

So, after reading this (it appears that globalspec is not commercial website):

And watching Knife Steel Nerds discussing quenching oils:

I've concluded:

1. You should not use Canola

2. Parks AAA and Parks 50 is pretty pricey. Importing it to Belize costs 2x due to shipping

So, to avoid paying almost 500 bucks for Parks 50, have any of you found any article or tests done by anyone or yourself on other quenchants like hydraulic fluid?

Ron

Note that this question refers to quenching knives made out of 80CRV2, 1095 and whatever steel leaf spring and farrier rasps are made of (for now) using a gas forge.

Ron

-

It appears that the aspect of a forge is nearly a science on its own. I really regret not asking questions before buying. Vevor actually has a two burner forge, same design, for about 60-70% of the cost of the three burner.

Instead of cutting a 1/3 off it, can't I just shove a fire brick the dimensions of the casted opening of the forge through the "back". Assuming my casting is square, I should be able to cut a fire brick with the opening dimensions and shove as far in as needed. I can coat the fire brick for good reflectivity. Just a thought.

I also have about 1.5 sheets of 1/8" (about 10 gauge) metal sheeting lying around if holes appear eventually. It appears, after buying additional blanket material, I had enough materials at home to build my own forge and avoid paying the Chinese company $250 bucks for their product. We learn as we go...

In regards to the temp, it's a Chinese product and we all know how inconsistent their printed materials are. This is also included with my forge description. Is anyone familiar with that regulator? I heard it's junk and should be replaced. I'd appreciate some feedback on that as well.

Can you expand a little more on this?

5 hours ago, Latticino said:...the "front" door should be set to close with a castable against castable seal, be oriented so in the open position the hot face isn't pointed towards the user..

I can change the hinge door to a system that slides to the side. I have somewhat mediocre fabrication skills. However, the forge body opening already has bent edges (for rigidity I guess), so I'm not sure I can cast on top of that.

-

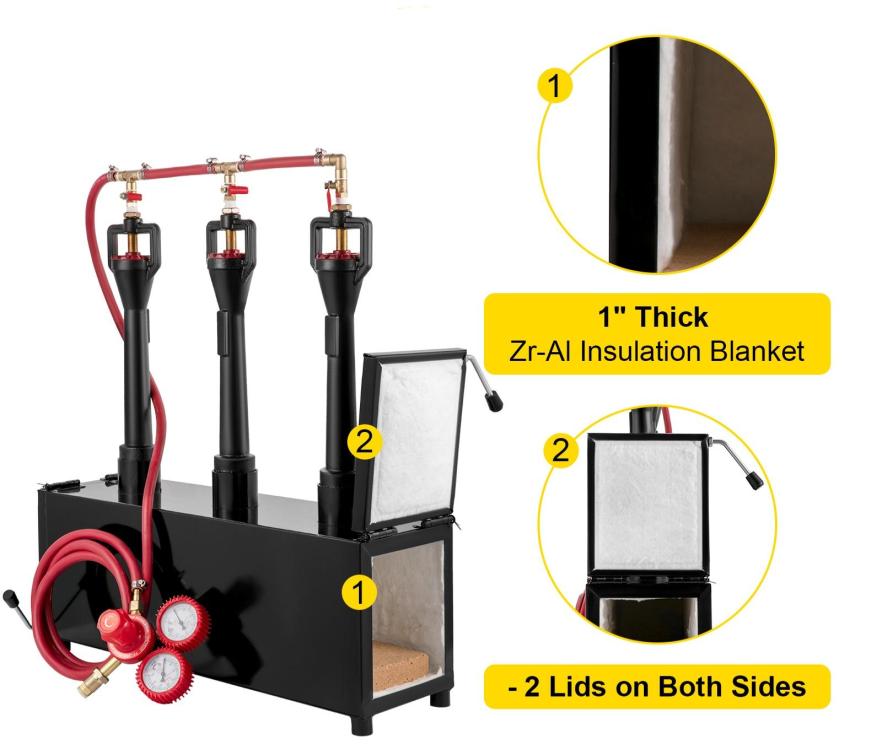

Thank you for the clarifications. And I have one big huge apology to make. I posted the pic of the wrong forge. I already bought it and don't want to mess with it until I have the rigidizer and coating materials at hand, hence why I'm posting pics from the marketing material included with it.

This is definitely it.

Why I bought a three burner thing? Because I'm a knucklehead impulsive buyer and didn't read enough before clicking "add to cart". I wonder if there is anything I can do before putting the castable refractory on the ceiling to keep it in place over time and avoid the sagging you mentioned. I have a lot of expanded metal mesh around leftover from another project and wonder I can't encase the walls and ceiling of the rigidized insulation before plastering the Kastolite...

The air metering here seems pretty remedial and easy to manipulate (in my head at least).

And I hope the valve issue you mentioned may be fixed with this design other than the other. Sorry for wasting your time with the other pic. But, it is not all useless, as now I know in case I purchase or build another one in the future if all goes right with this one.

2 hours ago, Latticino said:Have you checked in with Craig Kovach from Island Forge and Fab? His profile lists him as a bladesmith in Belize. He may be able to help you directly...

Are these members of IFI? I'll see if I can lookup members and if you can reach them privately. I searched high and low on google, facebook etc if anyone was remotely in the hobby for networking and I can perhaps visit them for direct demonstrations. Anddddd I found no one.

-

Thank you guys. This is how the forge would look assembled according to the pamphlet.

[IMAGE]

I'll do as Latticino and Frosty suggests. Please correct me if misunderstood:

1. Get the layers of fabric nice and wet

2. Coat with fumed silica solution as thick as allowed on second layer only.

3. Get it dry for some days

4. Plaster rigidized fiber with refractory like Kastolite 30. Let it dry as per instructions

5. If budget allows, I may use that Zirconia/Silica refractory coating on top of the Kastolite.

From the very few video reviews of the forge, it seems that all I may need to do to make it more decent is add more cushion, replace the regulator and those plastic hoses.

Thank you. I'll report back once I get something hot with it. It'll be used for forging knives and because I'm cheap and a beginner, to perform all the heat treating steps. No forge welding for now.

Ron

-

I have pretty much no rep points to suggest anything here. But may I suggest reviewing Rule 7 tip #5? Links to amazon or whichever website makes shorter posts than posting pics and explaining a specific product, which we may do wrong if not carefully described. Perhaps the tip can be changed to "No affiliated links to commercial websites". Just my 2c.

I just made my first post somewhere else, and I violated this rule as I posted that before reading this. I'm unable to edit. Sorry. I can recreate that post if necessary.

Ron

-

Hi,

First post here. I'm from Belize, and I may well be it's first bladesmith aspirant in couple of months.

I bought one of these vevor forges (not promoting, just giving enough details to my post)

It comes with one 1" layer of unrigidized ceramic fiber, to which I'll add another 1" for added insulation. Here are my questions:

1. Do I rigidize each layer separately before inserting the next layer of fiber?

2. Is this product (100% pure hydrophilic fumed silica powder) still acceptable for rigidizing? I already bought it based on what I read here, but now I'm reading, also here, that it may not be good. I appreciate your input:

3. I'm also considering buying the following as a top coat (65% Zirconia, 31% Silicone, and 1% alum). My questions in regards to this coat are: Is it necessary after rigidizing? Is there a better refractory coat to apply after rigidizing?

Because I'm not buying a commercially designed rigidizer, I don't have instructions and the methods used vary a bit on this forum. I know it is mixed with water and dye and applied with a spray bottle. Can you clarify the following as well:

1. What is the preferred mixing ratio?

2. Is it left to air dry or do you light up the forge?

3. Do you then re-apply other coats once the first coat is dry?

If you have further recommendation on what to do with the forge I bought, please drop them here. I don't mind the reading and I appreciate all the help on the aspect of the forge I can get.

Thank you

Ron

Kastoloite 30, sourcing or alternatives

in Insulation and Refractories

Posted

I had a chat with Atlas Knife and Tools. They say that Kastolite products are for monolithic casts. Meaning, using the castable on its own inside a form and not on top of wool. They recommended using plistix 900 alone on top of the wool. What's your view on that?

Ron